Combined matrix for sewage treatment of subsurface wetland and treatment system

A sewage treatment system and subsurface flow wetland technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc. Damaged and clogged, reduced sewage purification efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

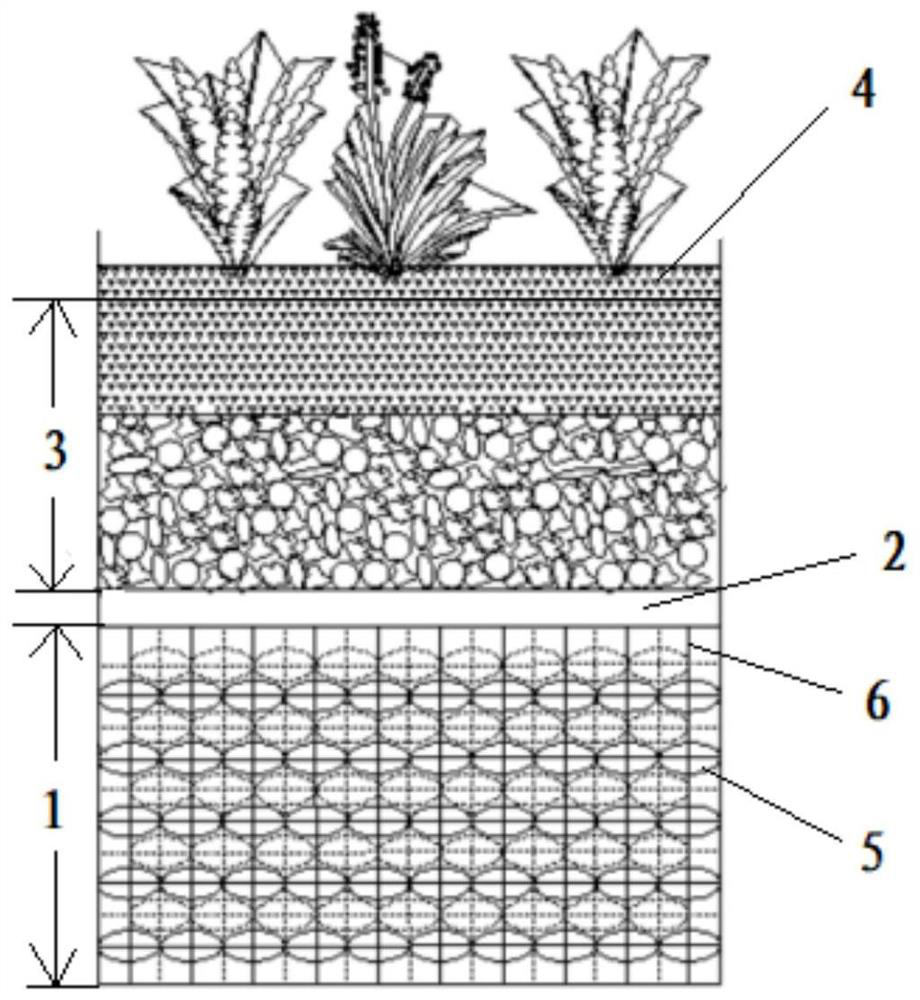

[0068] A subsurface flow wetland sewage treatment system, comprising a combined matrix, a planting layer 4 is set on the top of the hard packing unit 3, and plants with degradative properties for sewage are planted in the planting layer 4; sewage flows from the combined packing unit 1 , flows into the planting layer 4 after flowing through the isolation unit 2 and the hard filler unit 3 . Among them, the composite matrix is:

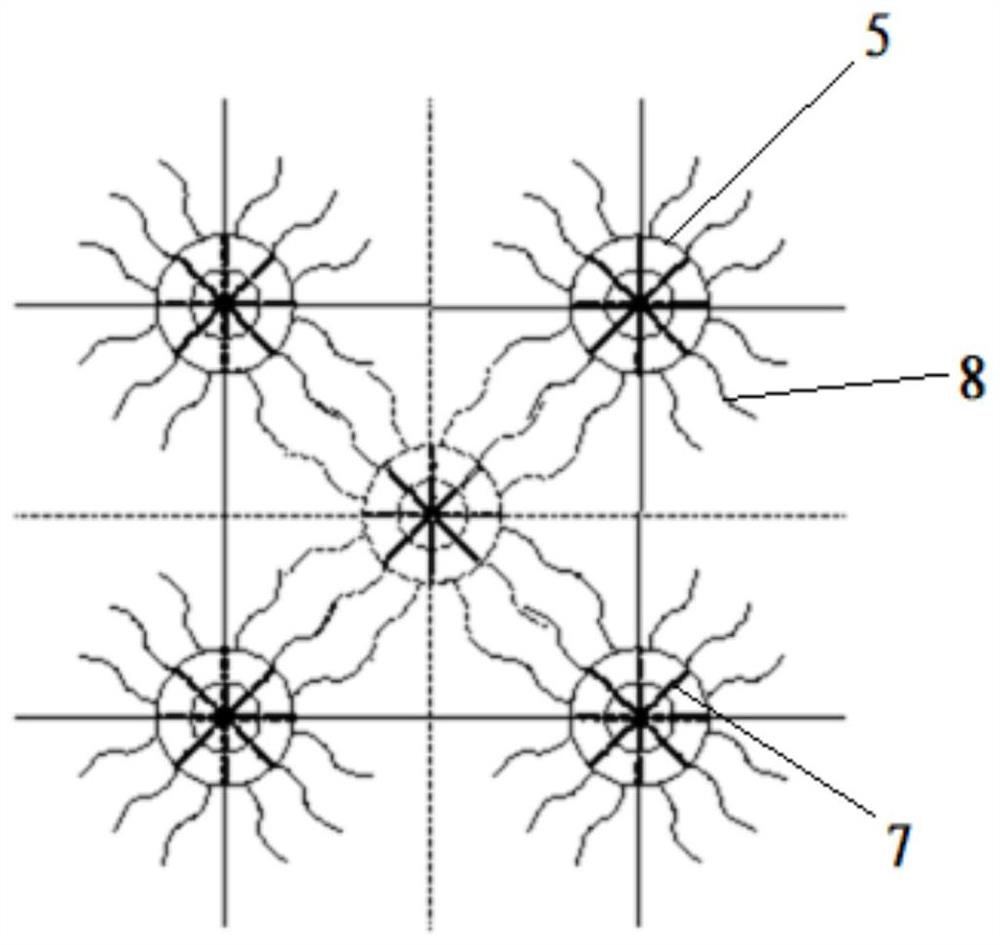

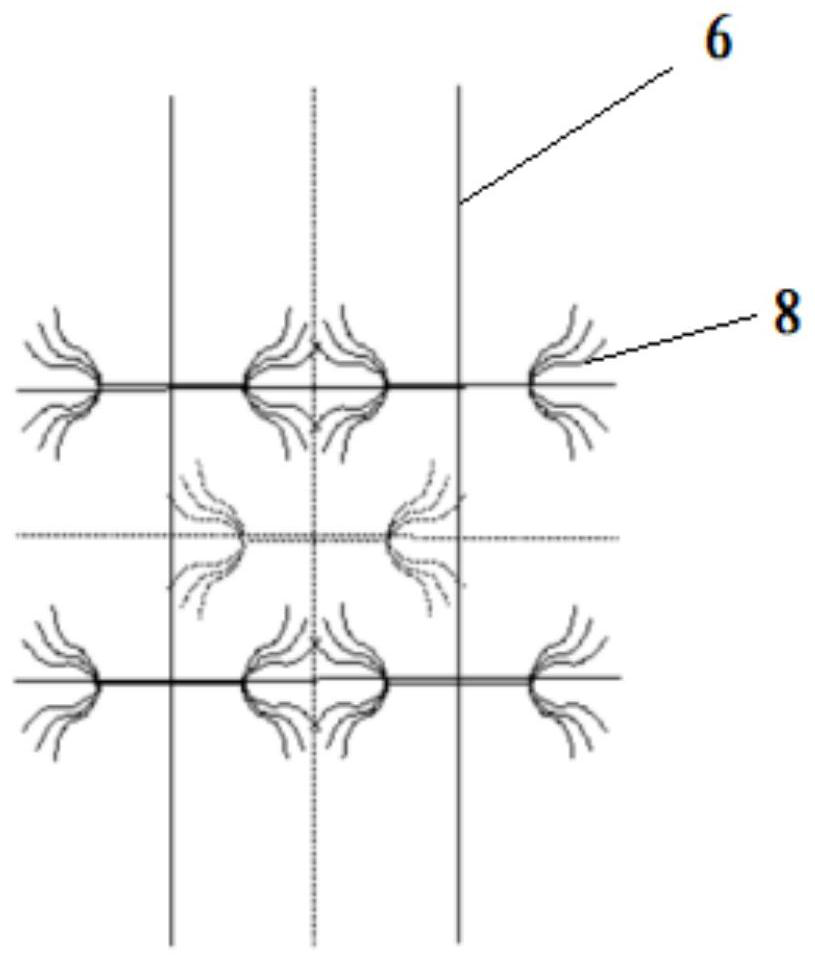

[0069] like figure 1 , figure 2 As shown, a combined substrate for sewage treatment in subsurface wetlands, including combined packing unit 1, isolation unit 2 and rigid packing unit 3 arranged in sequence, the sewage water flow direction is from bottom to top, combined packing unit 1, isolation unit 2 and rigid packing units 3 are sequentially arranged from bottom to top according to the flow direction of wetland sewage; the combined packing unit 1 includes a multi-layer skeleton structure and several central ropes 6 arranged perpendicular to the ske...

Embodiment 2

[0075] A subsurface flow wetland sewage treatment system, comprising a combined matrix, a planting layer 4 is set on the top of the hard packing unit 3, and plants with degradative properties for sewage are planted in the planting layer 4; sewage flows from the combined packing unit 1 , flows into the planting layer 4 after flowing through the isolation unit 2 and the hard filler unit 3 . Among them, the composite matrix is:

[0076] A combined substrate for sewage treatment in subsurface wetlands, including a combined packing unit 1, an isolation unit 2 and a rigid packing unit 3 arranged in sequence, the direction of sewage water flow is from bottom to top, and the combined packing unit 1, isolation unit 2 and rigid packing The unit 3 is arranged in order from bottom to top according to the flow direction of wetland sewage; the combined packing unit 1 includes a multi-layer skeleton structure and several central ropes 6 arranged perpendicular to the skeleton structure; each ...

Embodiment 3

[0082] The method for treating sewage in the subsurface flow wetland sewage treatment system in embodiment 1-embodiment 2 comprises the following steps:

[0083] (1) The sewage is introduced into the subsurface flow wetland, the sewage enters the combined packing unit, and the microorganisms grow in the combined packing unit. The growth period of the microorganisms is 21 days. After the microorganisms grow, the microorganisms degrade the pollutants in the sewage, and at the same time The cage structure in the combined packing unit intercepts the suspended particles in the sewage;

[0084] (2) The sewage treated by the above-mentioned combined packing unit enters the rigid packing unit after passing through the isolation unit, and the pollutants in the sewage are filtered, intercepted, adsorbed, and undergo chemical reactions through the rigid packing unit to achieve the purpose of sewage purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com