Seam beautifying agent filling production line

A technology of beautifying agent and production line, applied in the field of beautifying agent filling production line, which can solve the problems of increasing the overall filling time, easy dripping of raw materials on the tank, and reduced efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

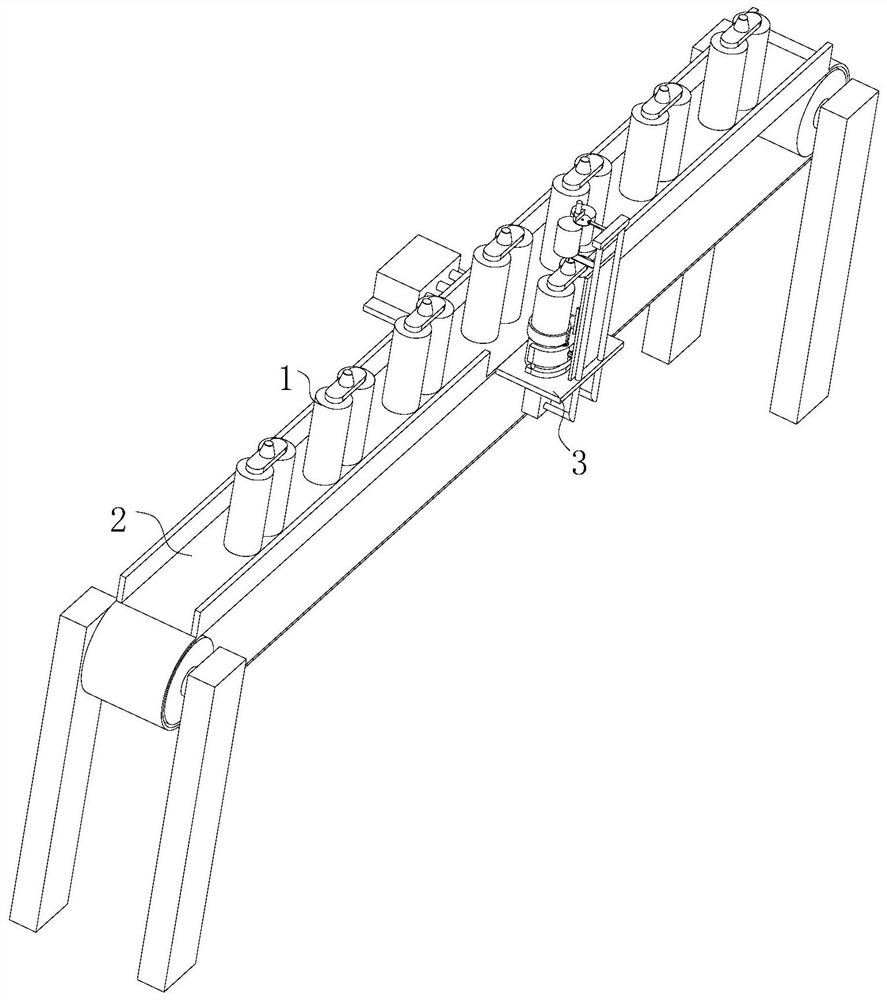

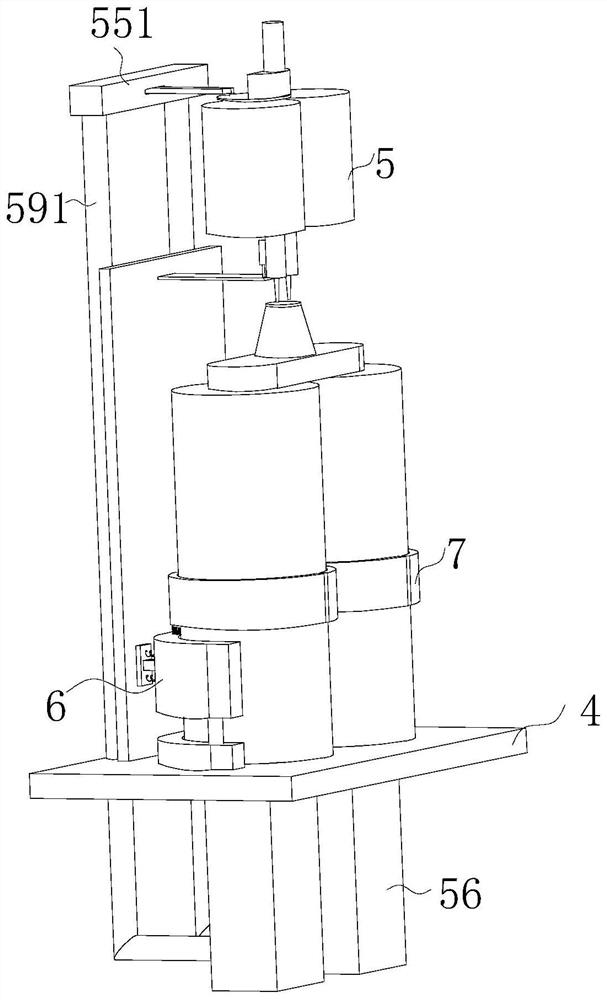

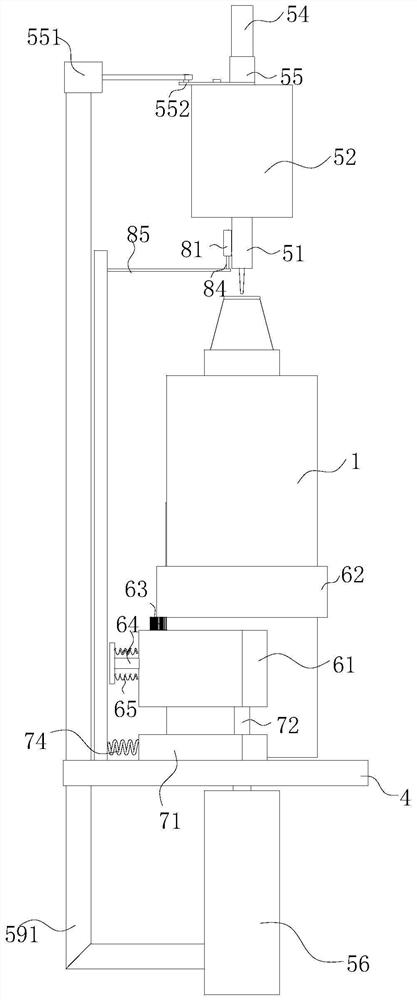

[0031] see Figure 1-11 , a beautifying agent filling production line, including a conveying line 2 for transporting two-component beautifying agent tanks 1 and a filling mechanism 3 fixedly arranged on the side of the conveying line 2, the filling mechanism 3 includes a mounting seat 4. A clamping unit 6 , a cleaning unit 7 and a filling unit 5 are fixedly installed on the mounting base 4 , and the filling unit 5 is used for the two-component cosmetic agent tank 1 fixed by the clamping unit 6 . The tank body is filled at the same time and the filling is completed at the same time; the cleaning unit 7 is used for synchronous cleaning of the two tank body surfaces of the two-component cosmetic agent tank 1 when the filling unit 5 is filling.

[0032] The commonly used two-component beauty joint agent is formed on the basis of a single-component beauty joint agent, and it usually consists of two components, AB and AB. At present, in the production of two-component beautifying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com