Apparatus for the separation of plasma

An equipment and plasma technology, applied in filtration separation, separation method, semi-permeable membrane separation, etc., can solve the problems of no filling, no usable amount, different liquid filling channel rates, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

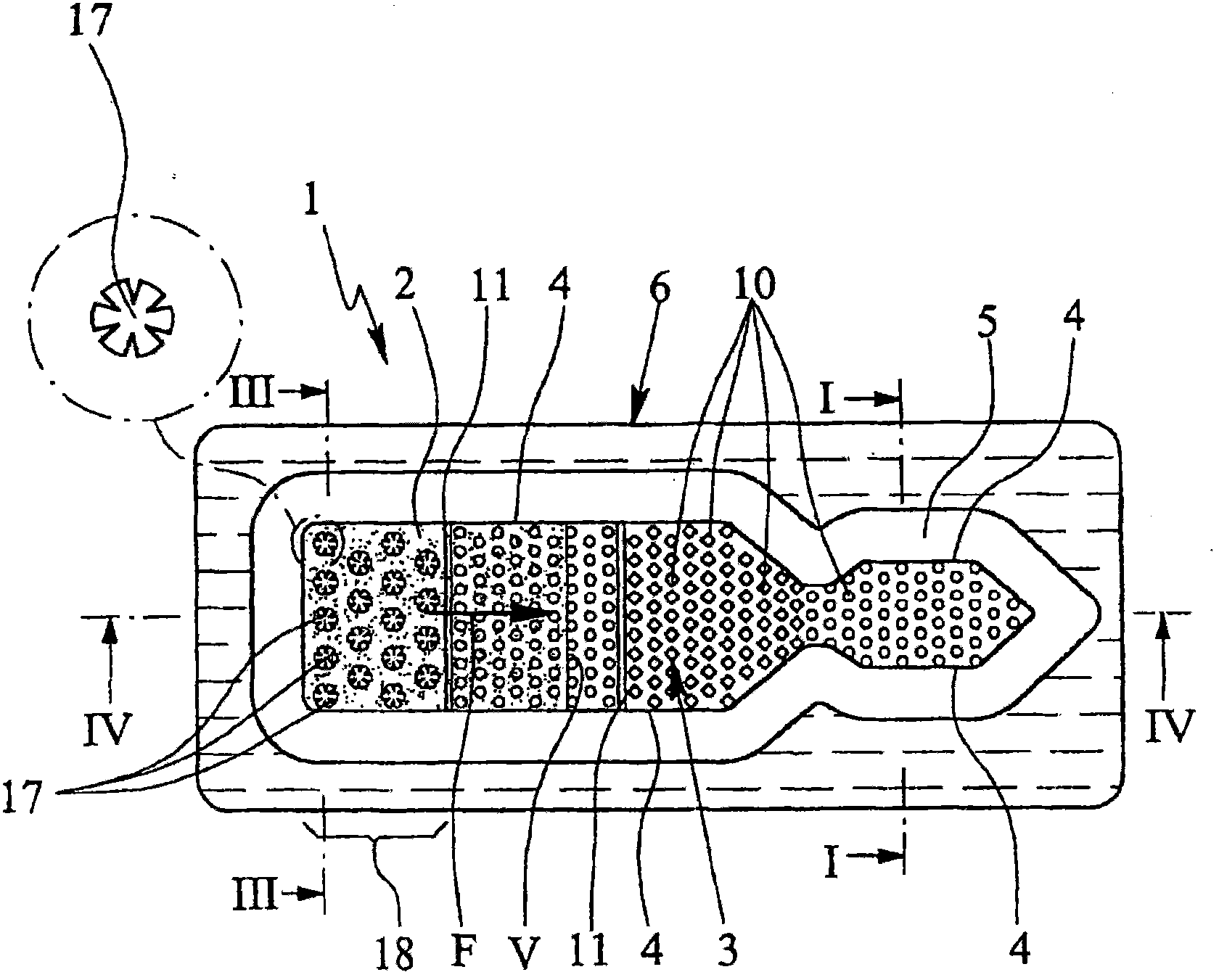

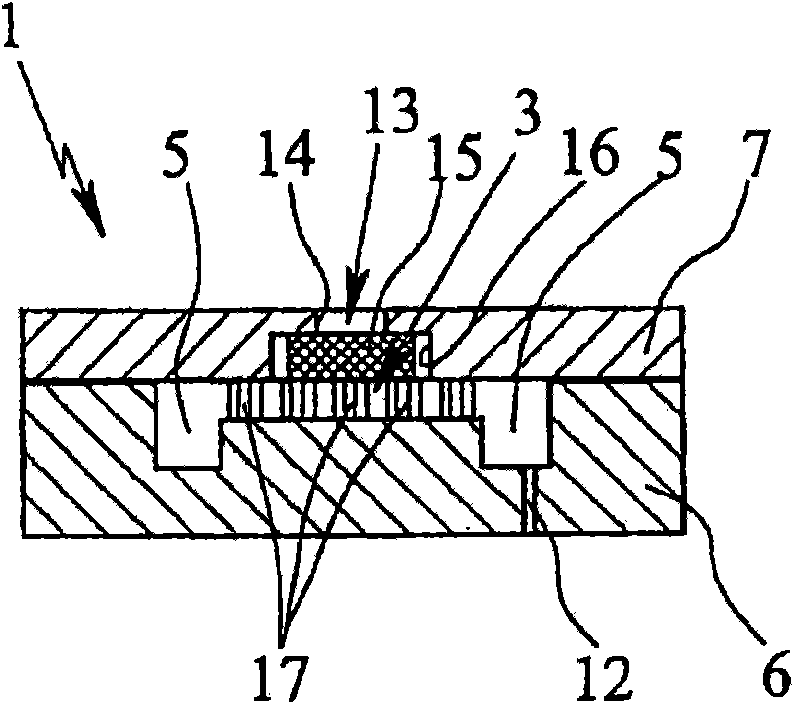

[0031] In the drawings, the same reference numerals are used for the same or similar parts, but corresponding or comparable properties and advantages can be realized even without repeating the related description.

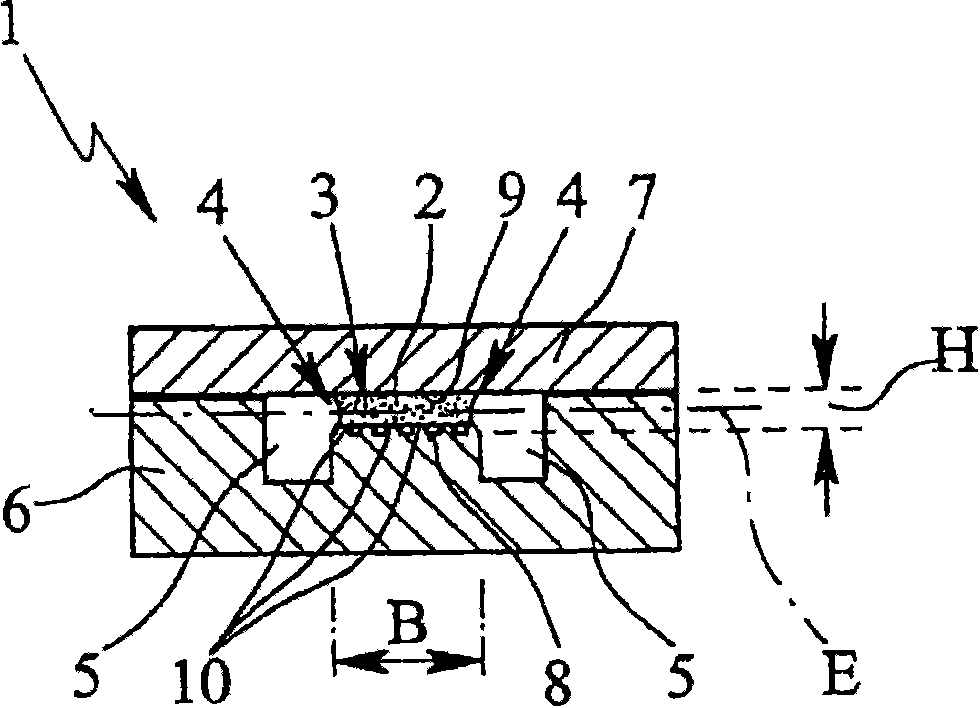

[0032] figure 1 In a schematic section, a first embodiment of the proposed device 1 for absorbing and / or analyzing a sample liquid 2 (in particular blood plasma or the like) is shown. The device 1 has a channel 3 which draws sample liquid by capillary force. Channel 3 is open at least on one narrow or longitudinal side 4, in figure 1 In the exemplary embodiment shown, both narrow or longitudinal sides 4 are open.

[0033] Finally, adjoining the open side 4 is a recess 5 , which in the embodiment shown is preferably groove or groove-shaped.

[0034] Thus, a lateral liquid barrier (and thus a flow obstacle that cannot be overcome by capillary forces) of the sample liquid 2 is formed in the channel 3, and the sample liquid 2 can follow the open side 4 in the channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com