Wheel hub accompanying loading device for automobile manufacturing and machining

A technology of automobile manufacturing and loading device, which is applied in the field of automobile manufacturing, and can solve the problems of high operation difficulty, affecting the stability of wheel hub disassembly and assembly, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

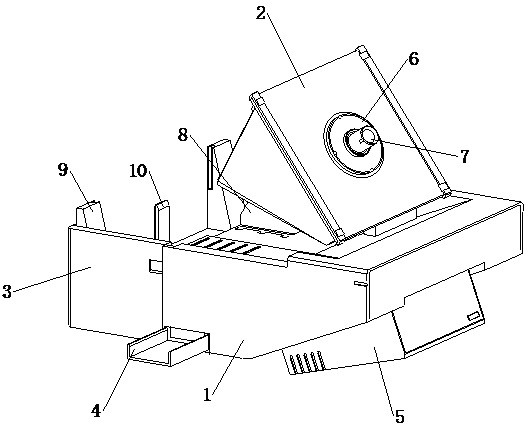

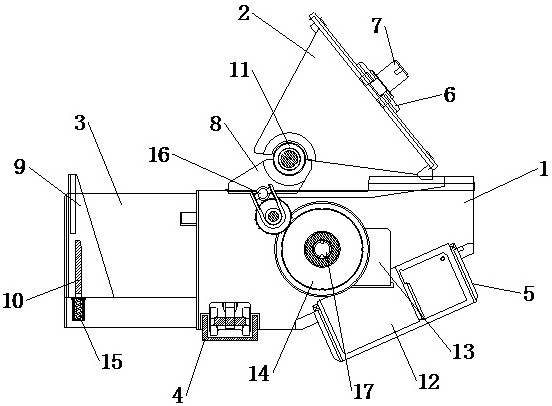

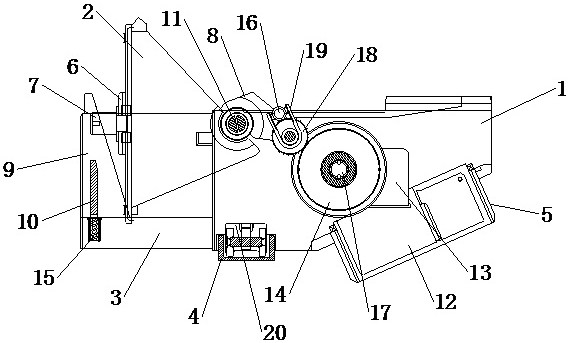

[0030] combine Figure 1-Figure 6 , the invention discloses an accompanying loading device for automobile manufacturing and processing hubs, comprising a loader base 1, a hub base 2, a rail plate frame 3 and a wiring box 5, the hub base 2 is adjacently arranged on the upper end of the loader base 1, and the rail plate The frame 3 is plugged and arranged on the back of the loader base 1, and the wiring box 5 is fixedly arranged at the lower end of the loader base 1;

[0031] A bearing shank 6 is embedded in the middle of the front of the hub seat 2, a shaft roller 24 is installed through the bearing shank 6, an assembly shaft head 7 is inserted into the shaft roller 24, and an air cylinder is mounted on the inner side of the hub seat 2. 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com