Little bear iron sheet manufacturing equipment

A technology of iron sheet and equipment, which is applied in the field of bear iron sheet production equipment, can solve the problems of high labor intensity, low labor intensity, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

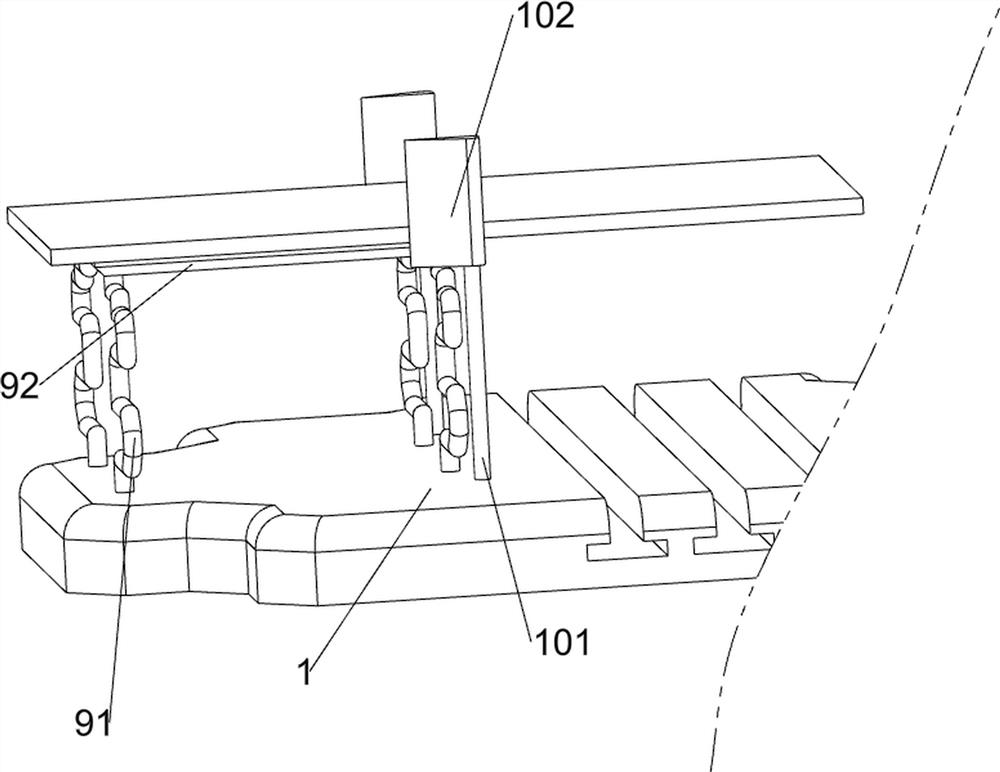

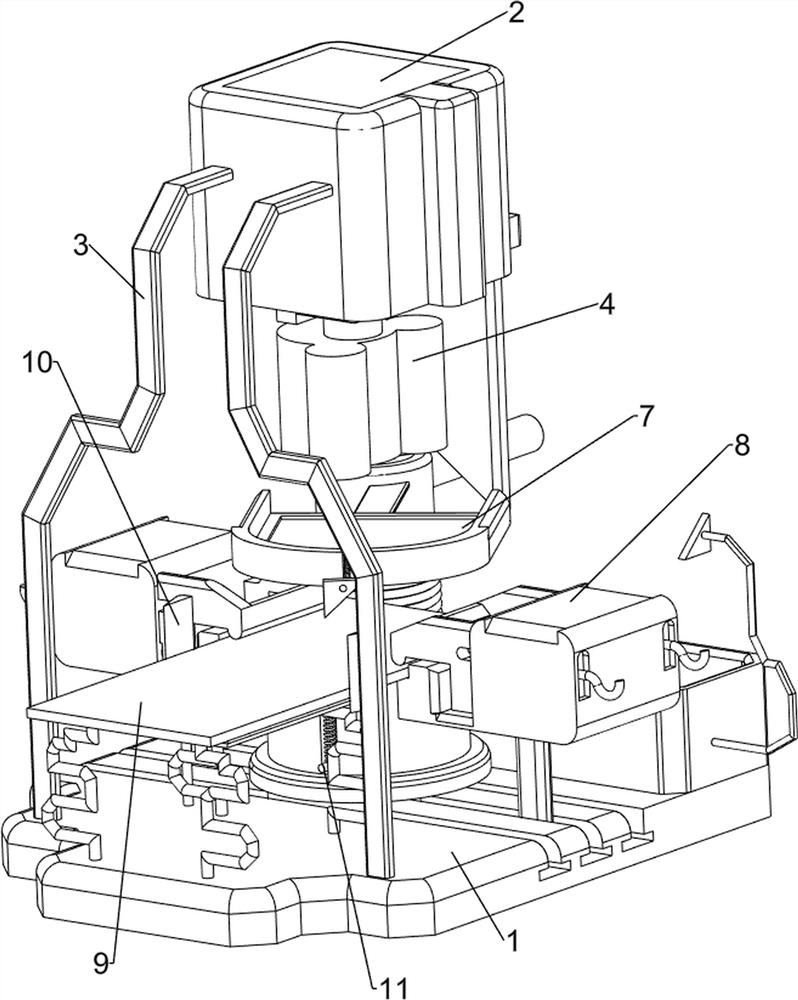

[0059] A bear tin making equipment, such as figure 1 and figure 2 As shown, it includes a base plate 1, a cylinder 2, a first support frame 3, a pressing column 4, a clamping block 5, a forming column 6, a discharge mechanism 7 and a clamping mechanism 8, and the left and right sides of the upper part of the base plate 1 are connected with the second A support frame 3, a cylinder 2 is connected between the rear sides of the first support frame 3, the end of the telescopic rod of the cylinder 2 is connected with a lower pressure column 4, the bottom plate 1 is slidably connected with a block 5, and the upper side of the block 5 is connected with a The forming column 6 is connected with a discharge mechanism 7 on the telescopic rod of the cylinder 2, and the left and right sides of the bottom plate 1 are all slidably connected with a clamping mechanism 8.

[0060] When the device needs to be used, the user can pull the clamping mechanism 8 to the outside, then put the iron she...

Embodiment 2

[0062] On the basis of Example 1, such as image 3 As shown, the discharge mechanism 7 includes a first wedge block 71, a support column 72, a first spring 73, a fixed rod 74, a discharge tray 75, a second wedge block 76, a charging box 77, a second support frame 78 and The third wedge-shaped block 79, the first wedge-shaped block 71 is connected on the expansion rod of the cylinder 2, the support column 72 is connected with the rotary type in the base plate 1, and the first spring 73 is connected between the support column 72 outside and the base plate 1, and the support column 72 The rear side is connected with a fixed rod 74, the right side of the support column 72 is connected with a discharge tray 75, and the rotation type in the discharge tray 75 is connected with a second wedge-shaped block 76, and the rear side of the bottom plate 1 is connected with a charging box 77, and the charging box The right side of 77 is connected with a second support frame 78, and the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com