Waste gas filtering device for automobile coating workshop

A technology of exhaust gas filtration and coating, which is applied in the direction of dispersed particle filtration, gas treatment, and separation of dispersed particles, and can solve the problems of affecting the exhaust gas treatment work, slow exhaust gas flow rate, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

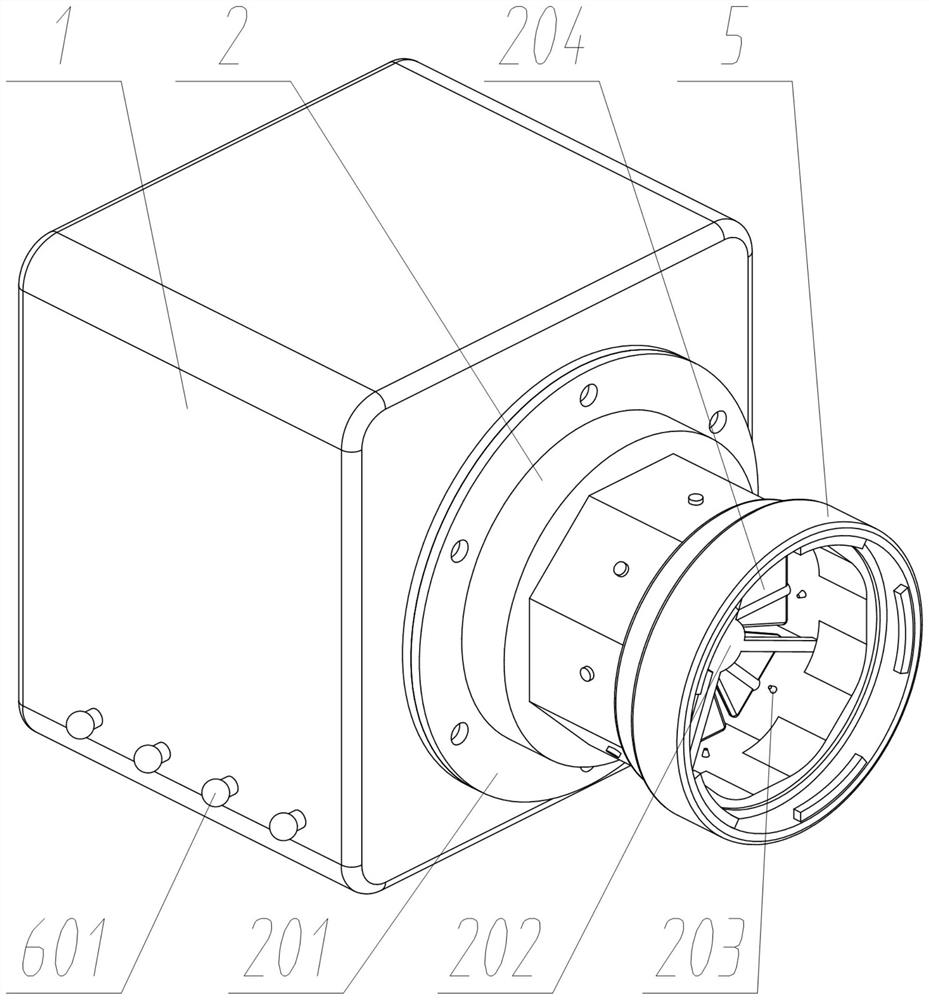

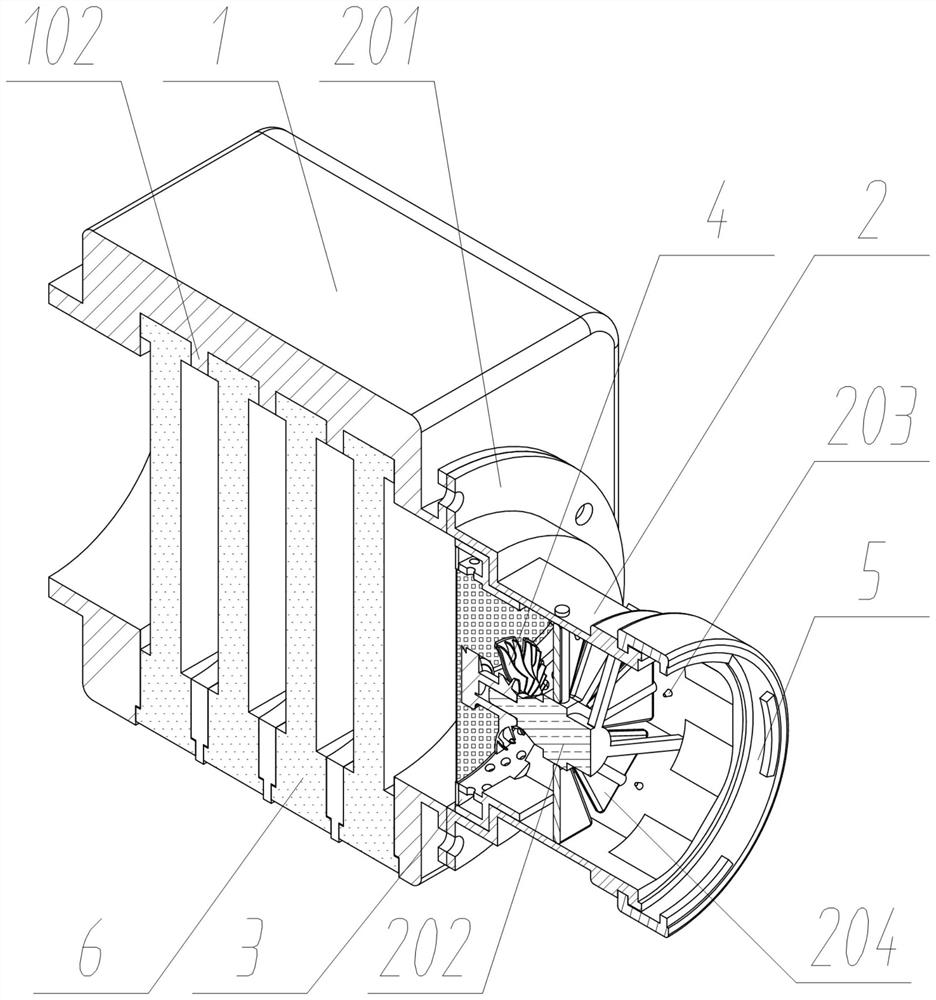

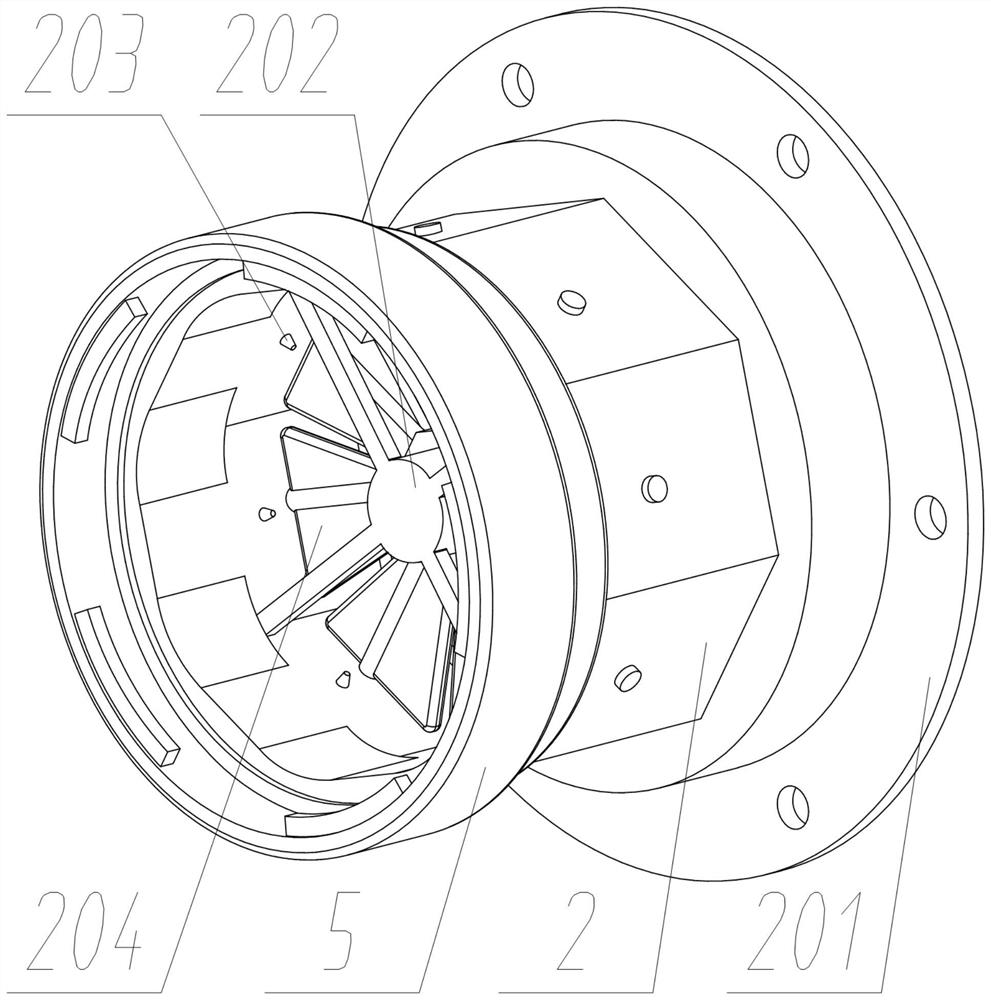

[0026] see Figure 1 to Figure 9 , a kind of embodiment that the present invention provides: a kind of waste gas filter device that automobile painting workshop is used, comprises filter box 1; Filter box 1 front part is fixedly connected with a group of suction tube 2; One-way fan 204 connected by hinges; a set of ash filter tube 3 is meshed and connected to the rear side of the suction tube 2, and a set of ash filter net 302 is connected to the rear of the ash filter tube 3; The impeller 4; the front part of the suction cylinder 2 is rotatably connected with a set of connecting rings 5; the inside of the filter box 1 is slidably connected with four sets of exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com