Mining electro-hydraulic control filter element cleaning device and cleaning method thereof

A cleaning device, electro-hydraulic control technology, applied in separation methods, chemical instruments and methods, fixed filter element filters, etc., can solve problems such as large resistance loss, reduced filter performance, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

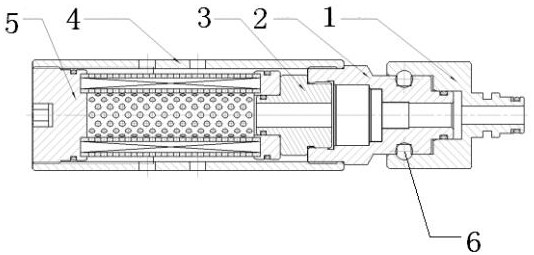

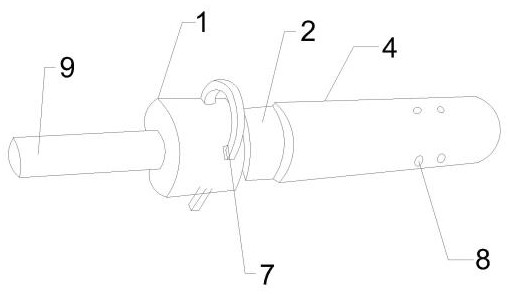

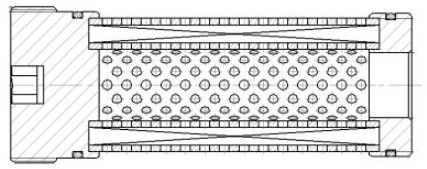

[0025] The specific embodiment of the present invention is: as Figure 1-3 As shown, a mining electro-hydraulic control filter element cleaning device includes an adapter 1, a connecting assembly, a housing 4, and a filter element 5. The body 4 is fixedly connected through a connection assembly, and the other end of the adapter 1 is connected to a mine filter element flow test bench 9, and the connection assembly includes a connection head 2, a connection sleeve 3, and a fixing piece 7. One end is provided with threads, one end is threadedly connected with the filter element 5, and the other end is threadedly connected with the connector 2, and one end of the connector 2 is concaved inward to form a card slot, and an internal thread is provided in the card s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com