Knife rest punching equipment for professional roller skates

A technology for drilling equipment and roller skates, applied in drilling/drilling equipment, metal processing equipment, applications, etc., can solve problems such as being unsuitable for mass production and easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

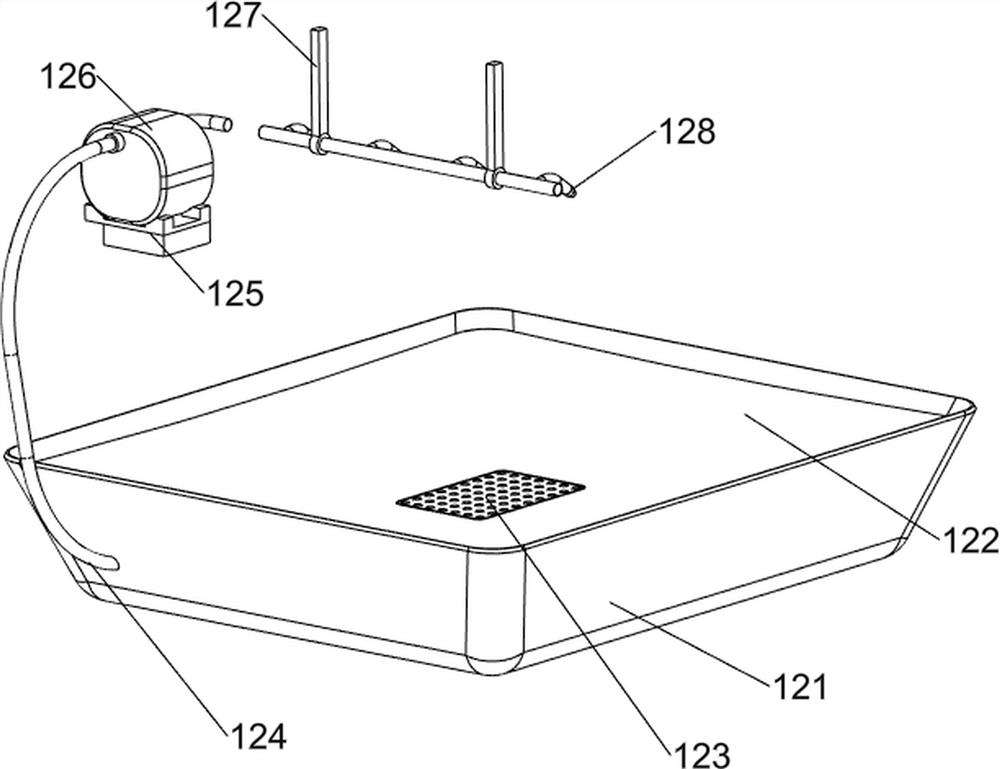

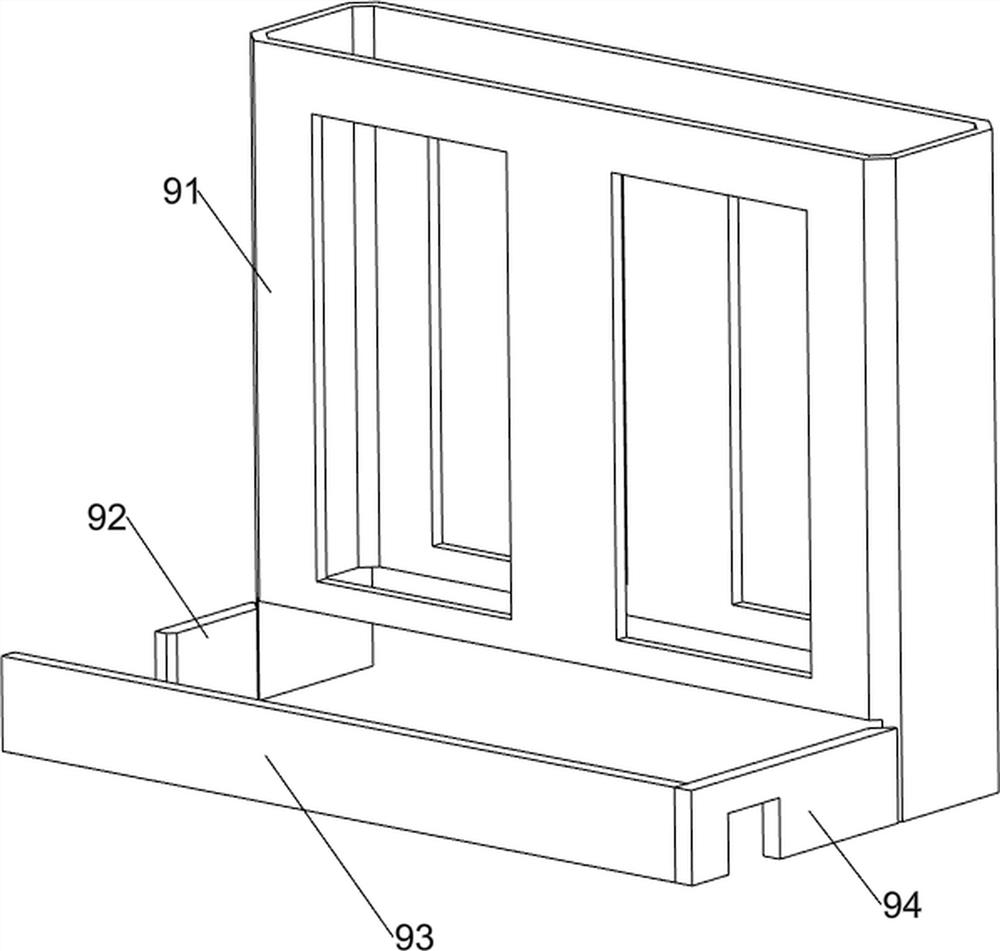

[0025] A professional wheel skating shoe with tool holder, such as figure 1 , figure 2 , image 3 with Image 6 As shown, including a bottom plate 1, a shelf 2, a drill bobbin 3, a drill 4, a cylinder frame 5, a non-standard gas cylinder 6, a block 7, a placement plate 8, a discharge mechanism 9, a retracting mechanism 10, and a mounting device 13, a bottom plate. 1 is provided with a shelf 2, and the upper portion of the shelf 2 is provided with a drill 4, and the drill frame is uniformly provided with a drill 4. The top of the shelf 2 is provided with a cylinder frame 5, and the cylinder frame 5 is provided with a non-standard cylinder 6, non-standard gas cylinder 6. The bottom and the cylinder frame 5 are connected, and the block 7 is provided on the right side of the drill bit 3, and the shelf 2 is provided with a plate 8, and the rear side of the plate 8 is provided with a discharge mechanism 9, and the lower portion of the shelf 2 is provided 13, shelf 2 The retracting mechani...

Embodiment 2

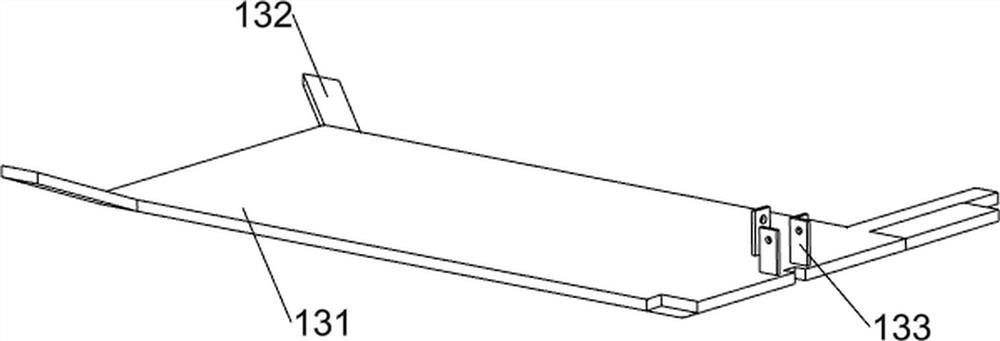

[0031] On the basis of Example 1, such as Figure 4 , Figure 5 with Figure 7 Shown, further comprising a feed mechanism 11, the feed mechanism 11 comprises a bevel gear set 111, a second shaft 112, spur gear 113, the third rack gear 114, a second guide rail 115, the second connecting rod 116, the third spring 117, the slider 118, 131 at the top right side of the guide post 119, the push plate 1110 and support frame 1111, a second mounting plate provided with guide rail 115, a third rack gear slidably connected to the guide rail 114 on the second 115, third tooth Article 114 is provided with a rear side of the second connecting rods 116, two rear gears rotatably supporting connection with a second shaft 112 between 133, 112 is provided with a second spur gear 113 on the shaft, a second shaft 112 and the right connected to a bevel gear set 111, bevel gear set 111 is formed by two bevel gears between the rear side of a shaft 106, two bevel gears are connected to the right rear side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com