Chamfer detection tool for brake pad steel backing and detection method of chamfer detection tool

A technology of angle detection and steel back, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large detection errors, poor detection efficiency, and lack of detection tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

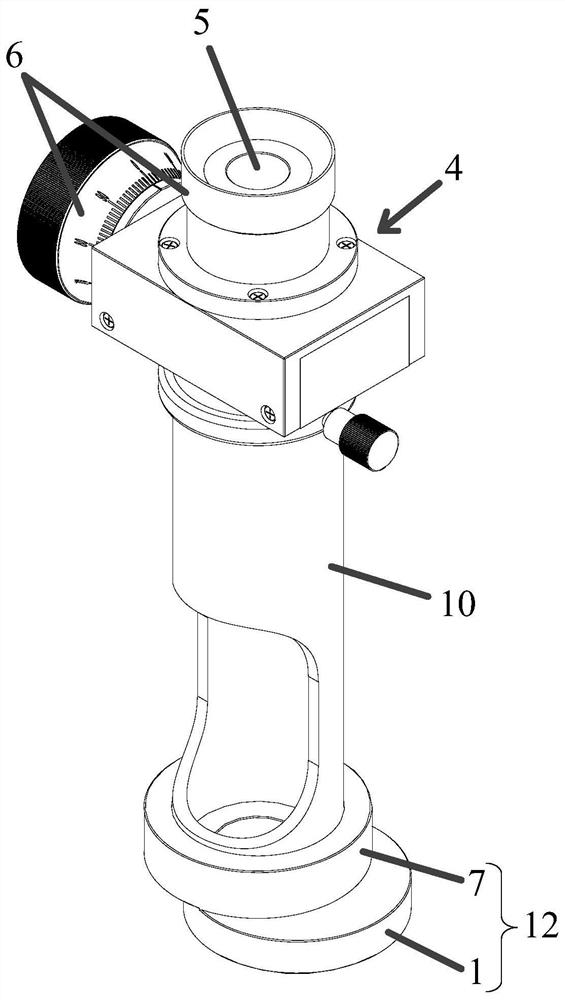

[0046] A chamfering inspection tool for the steel back of the brake disc is recorded, such as figure 1 with Figure 4 shown, which includes:

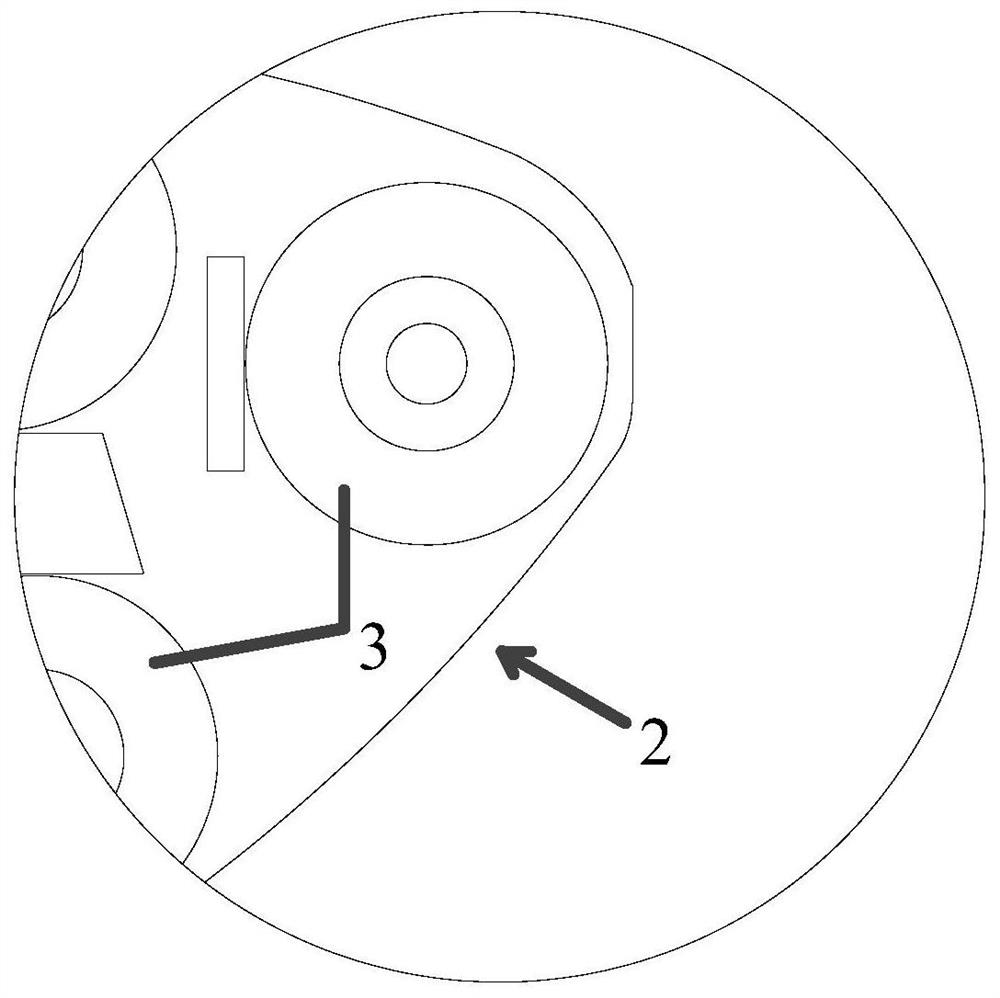

[0047] Embedded base 1, said embedded base 1 is as figure 2The shape of the friction block embedding groove 3 for embedding the friction block on the brake pad steel back 2 shown is matched;

[0048] Offset top seat 7, such as figure 1 As shown, the offset top seat 7 is fixedly arranged on the angle detection microscope 4, and is arranged non-concentrically with the embedded base 1 so that the angle detection microscope 4 is chamfered toward the outer contour of the friction block insertion groove 3 ; The embedded base 1 and the offset top 7 are integrally structured, and the two form a fixed outer diameter centering device 12;

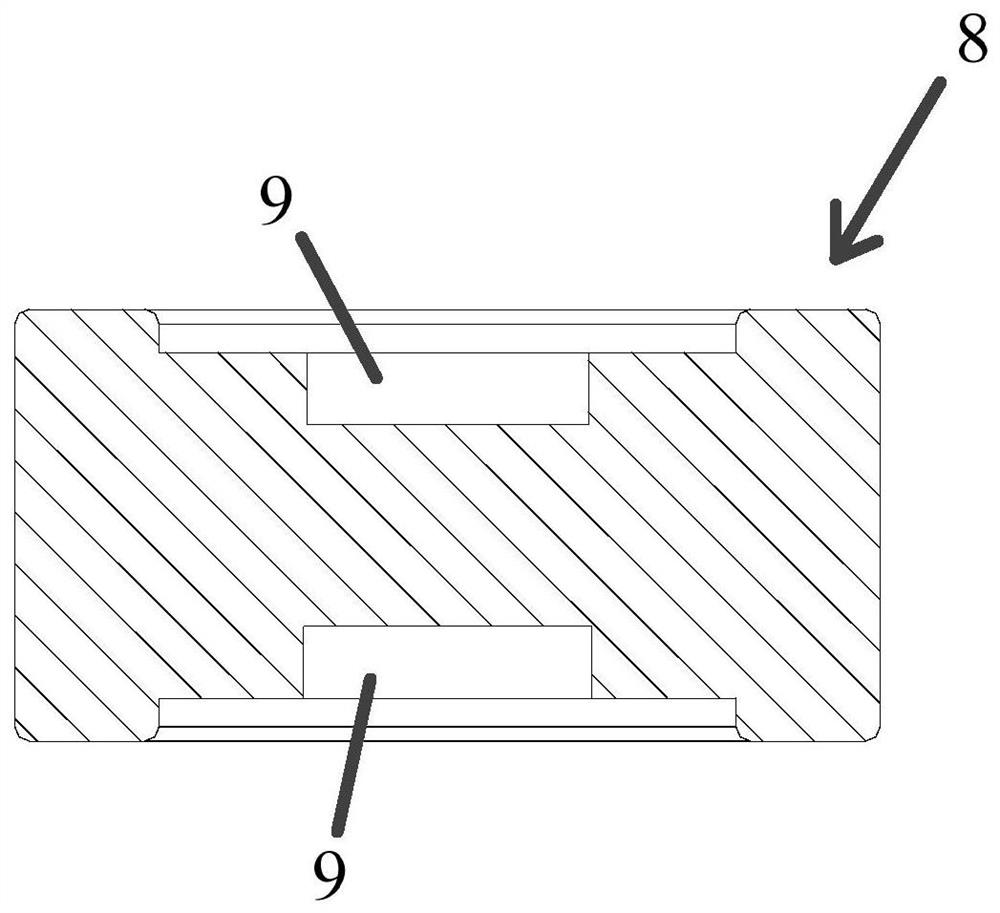

[0049] Angle detection microscope 4, such as figure 1 As shown, the angle detection microscope 4 is used to detect the chamfer diameter of the friction block embedded groove 3, which includes: a convex le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com