A kind of quick turnaround prefabricated steel structure and its construction method

A prefabricated, steel structure technology, applied in the field of machinery, can solve the problems of insufficient strain elasticity of the overall structure, insufficient strain resistance capacity, complex connection structure, etc., and achieve the effects of fast splicing and installation operations, saving resources, and flexible overall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

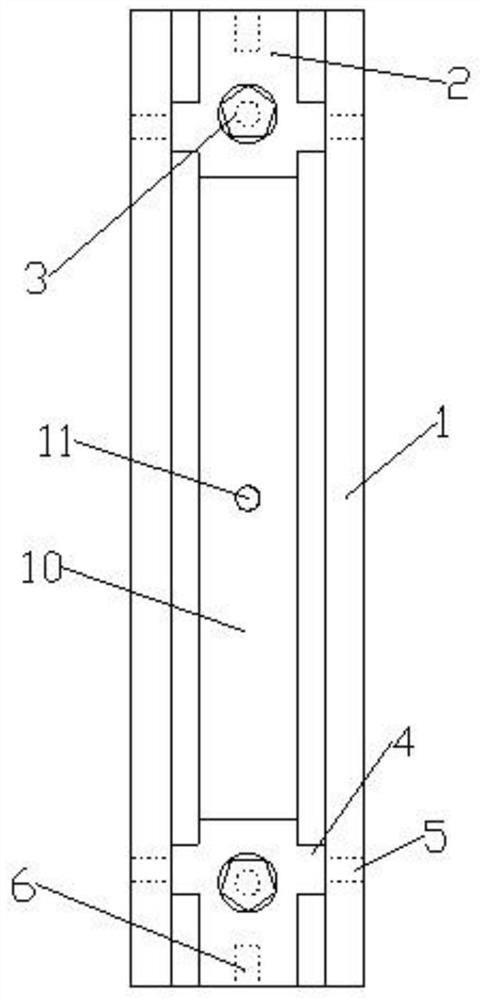

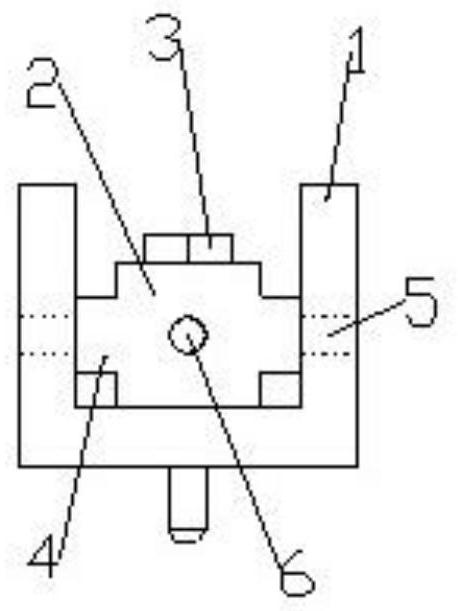

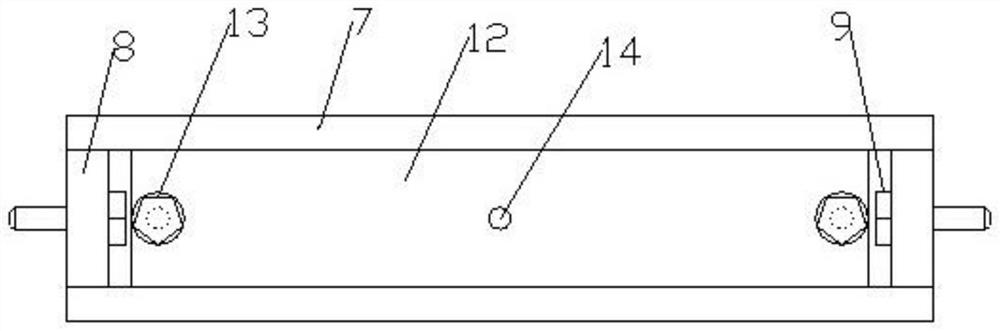

[0036] like figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, a quick turnaround assembled steel structure, including a first standardized main body part 1 and The second standardized main body part 7, the first standardized main body part 1 and the second standardized main body part 7 are both "凵" shaped channel steel structures, the height and width of the first standardized main body part 1 and the second standardized main body part 7 are equal, the width and height of the first standardized body part 1 are equal, the width and height of the second standardized body part 7 are equal, the groove depth and width of the grooves opened on the first standardized body part 1 and the second standardized body part 7 All are equal, the cross-sections of the grooves opened on the first standardized main body part 1 and the second standardized main body part 7 are all square structures, and the grooves opened on the first standardized main body part 1 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com