Drainage assembly of washing device and washing device

A technology for washing devices and drainage components, which is applied to washing devices, other washing machines, textiles and papermaking, etc., and can solve problems such as drainage difficulties in drainage pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the washing device is any one of a washing machine and an integrated washer-dryer. Further, the washing device may be any one of a drum washing machine and a drum washer-dryer. Of course, the washing device can also be other similar products for washing the objects to be cleaned. For example a dishwasher.

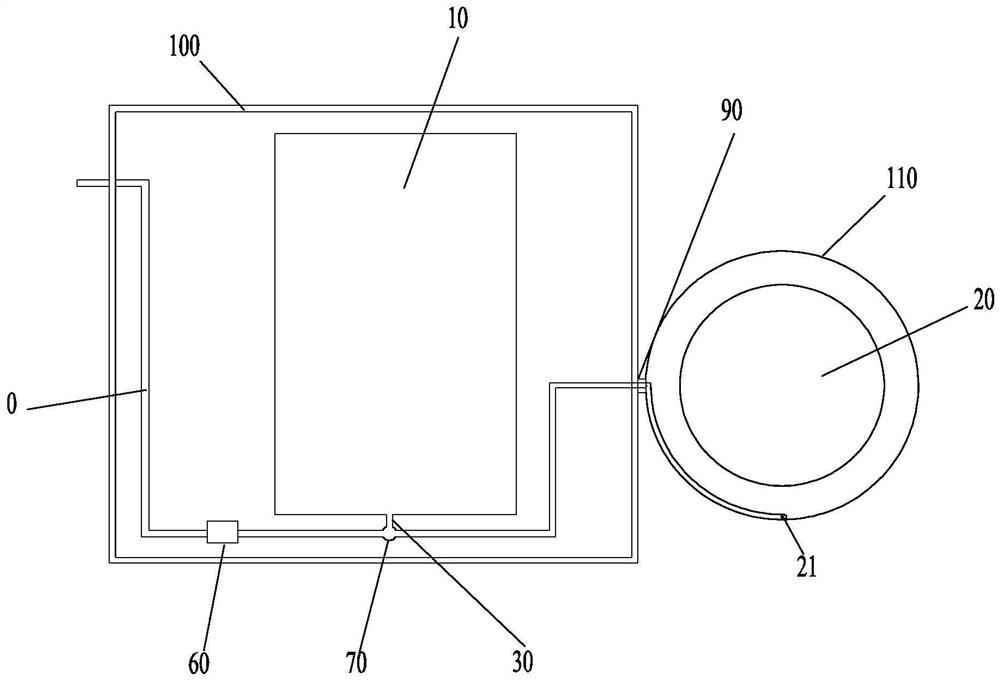

[0032] like figure 1 As shown, the drainage assembly of the washing device is arranged in the washing device. The washing device includes an outer cylinder washing chamber 10 and a door body washing chamber 20. The drainage assembly of the washing device includes an outer cylinder drainage pipeline 30 and a door body washing mechanism drainage pipeline 40. , the main drainage pipeline 50 and the drainage driving part 60. One end of the tub drain line 30 communicates with the tub washing chamber 10 . The door body washing mechanism drainage pipeline 40 is in communication with the door body washing chamber 20, and the height of the highest poin...

Embodiment 2

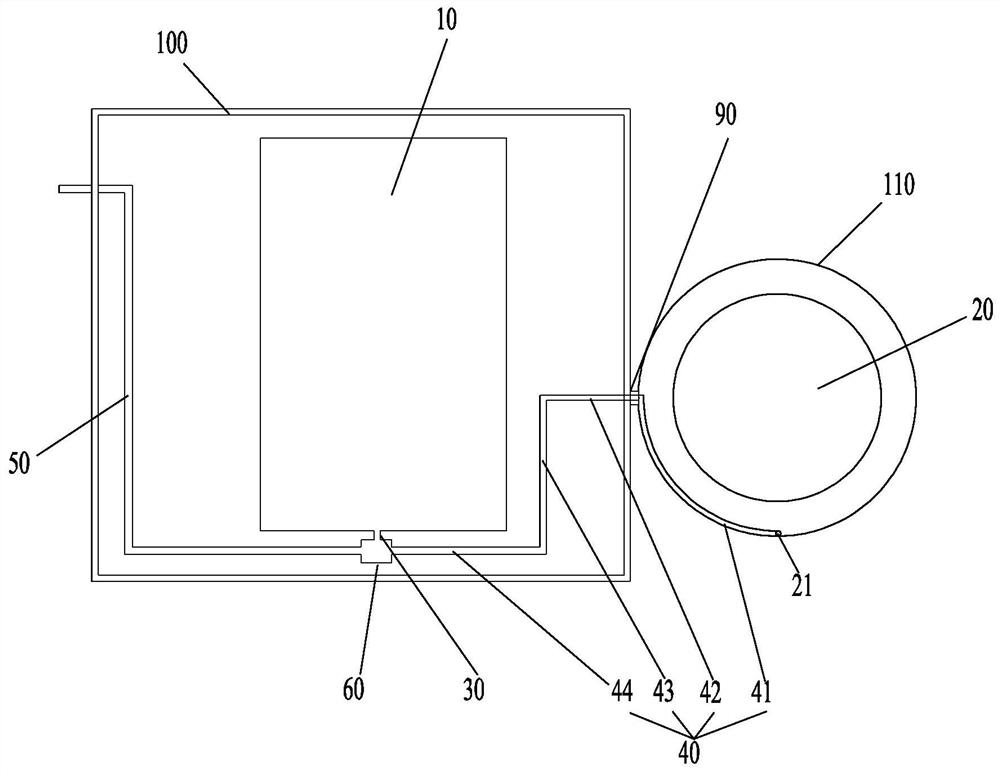

[0049] The difference from Embodiment 1 is that the arrangement of the drainage driving member 60 is different.

[0050] Specifically, such as figure 2 As shown, the drain assembly of the washing device in this embodiment does not include the three-way valve 70 . The drain driving part 60 communicates with the drain pipeline 40 of the door body washing mechanism, the outer cylinder drain pipeline 30 and the main drain pipeline 50 respectively. That is, the drain driver 60 serves as a three-way instead of the three-way valve 70 . This not only ensures the smooth connection of pipelines, but also reduces components and saves costs.

Embodiment 3

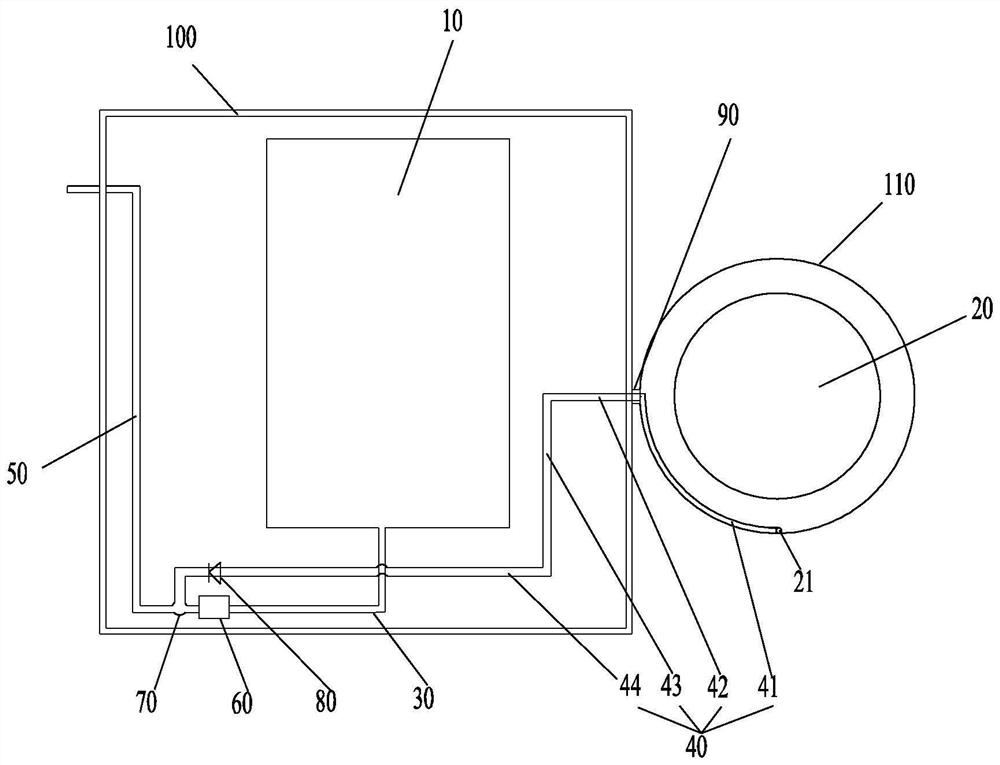

[0052] The difference from Embodiment 1 is that the arrangement of the drainage driving member 60 is different.

[0053] Specifically, such as image 3 As shown, the drain assembly of the washing device further includes a three-way valve 70 . The three-way valve 70 communicates with the drain pipeline 40 of the door body washing mechanism, the outer cylinder drain pipeline 30 and the main drain pipeline 50 respectively. The drain driver 60 is disposed on the outer cylinder drain pipe 30 . In this way, the three-way valve 70 is located downstream of the drainage driver 60, and the door body washing chamber 20 can directly communicate with the atmosphere through the door body washing mechanism drainage pipeline 40 and the main drainage pipeline 50, which is conducive to the formation of a siphon effect.

[0054] like image 3 As shown, the drain assembly of the washing device also includes a one-way flow member 80 . The one-way flow member 80 is arranged on the drain pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com