Movable car roof ladder applied to heavy public service rail car

A rail car and movable technology, which is applied in the direction of railway car body components, transportation and packaging, etc., can solve the problems of insufficient space for electrical cabinets and brake cabinets, affecting the opening of electrical cabinet doors, and insufficient height of car body assembly, etc., to achieve good results. Practical application value, avoid redesign, easy to take off and hang the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

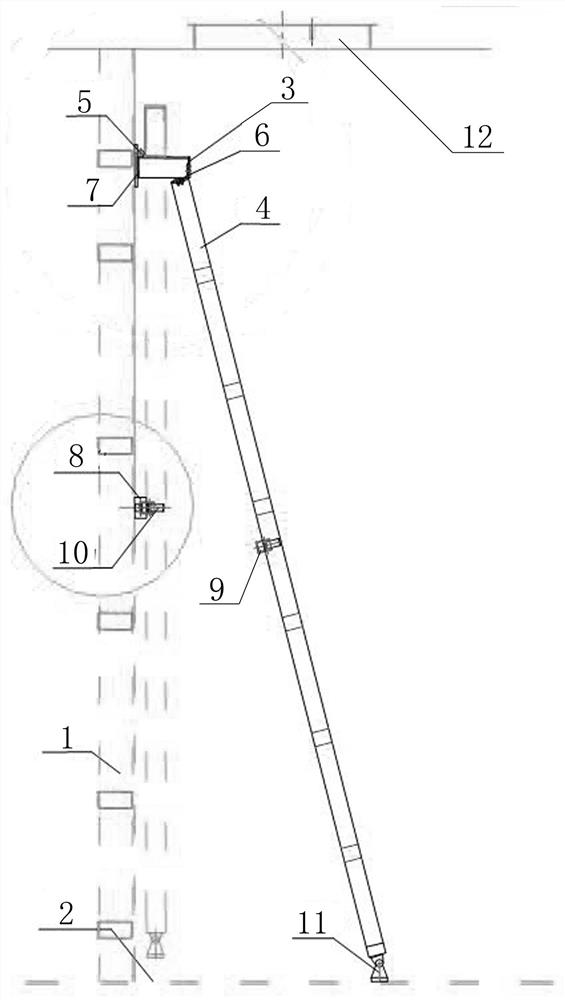

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

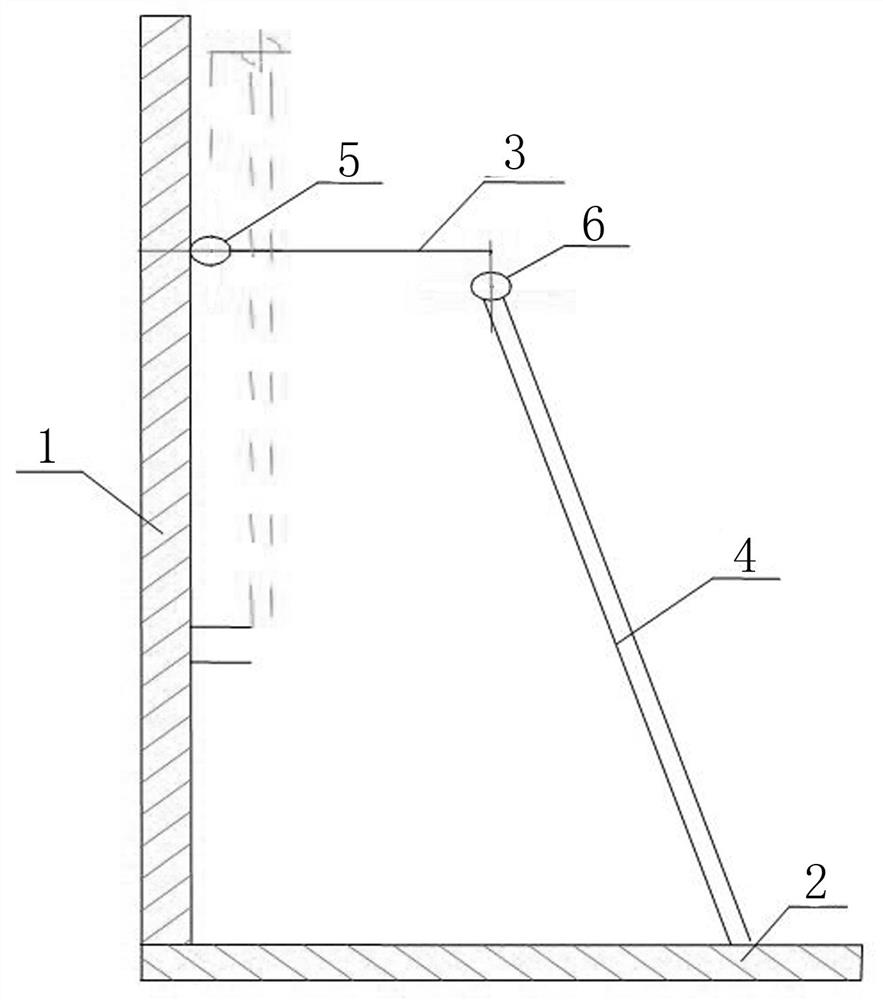

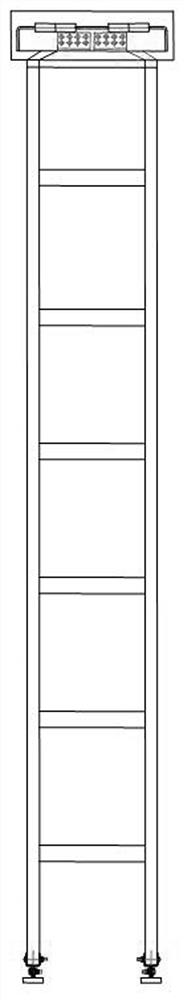

[0025] A movable roof ladder applied to heavy-duty public works rail cars, comprising a pedal 3 and a roof ladder 4.

[0026] Such as figure 2 , 3 As shown, the pedal 3 is installed on the partition wall 1 through the hinge 5, and the backing plate I7 is installed on the partition wall 1 at the hinge 5. When the pedal 3 is in use, it is perpendicular to the partition wall 1 and leans against the backing plate I7. When in use, it is parallel to the partition wall 1; that is, the pedal 3 rotates clockwise to a horizontal state during use, and the pedal 3 rotates counterclockwise to a vertical state after use.

[0027] Such as figure 2 , 3 As shown, the end of the pedal 3 is connected to the upper end of the roof ladder 4 through the hinge 6. When the roof ladder 4 is in use, its lower end is supported on the floor 2 at an angle. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com