Prestress assembled rail beam for stations and construction method thereof

A track beam and prestressing technology, which is applied in the field of rail transit, can solve the problems of small structure height, high structure height, time-consuming and manpower consumption, and achieve the effect of reducing the lifting height, reducing the structure height, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

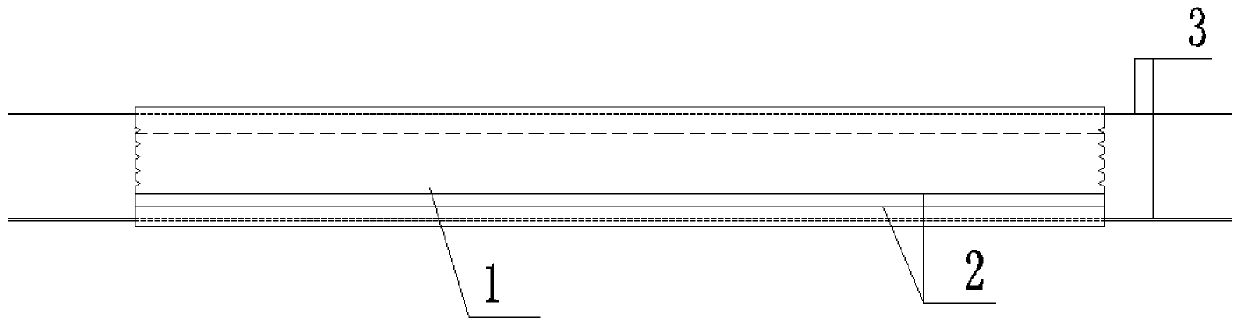

[0035] This embodiment discloses a prestressed assembled track beam for a station, such as figure 1 As shown, it includes: a track beam body 1, the track beam body 1 includes a flange 11, and two rib beams 12 vertically connected to the flange, and the two rib beams 12 are arranged oppositely to form a track beam body 1 with a double T-shaped cross section. A steel strand 2 is provided longitudinally through the two rib beams 12 .

[0036] Specifically, the distance between the double-rib beams 12 is 1400 mm, and a beam rib 12 is arranged under the corresponding rail platform of each rail, so that the force transmission path is more direct and the structure is more reasonable. The track beam body 1 is a prestressed structure. Through the setting of the prestressed structure, the height of the track beam body 1 can be reduced. At the same time, the applicable longitudinal column span is more flexible. The pretensioning method can be used for construction during factory prefabri...

Embodiment 2

[0038] This embodiment discloses a prestressed assembled track beam for a station, such as figure 2 and image 3 As shown, several track beam bodies 1 are connected by post-casting strips 4 to form a single-line longitudinally continuous prestressed assembled track beam.

[0039] In the above embodiments, the two ends of the track beam body 1 are provided with tooth grooves 111 to increase the shear bearing capacity of the joint surface between the prefabricated track beam body 1 and the post-cast concrete.

[0040] In the above embodiment, the track beam body 1 is pre-embedded with longitudinal steel bars 3 along the longitudinal direction. The longitudinal steel bars 3 include: beam top bars, beam bottom bars, and beam side bars, which can be connected by welding between bars and post-casting strips during construction. , In addition, other connection methods can be used to quickly overlap the track beam body to form a frame.

Embodiment 3

[0042] This embodiment provides another prestressed assembled track beam for a station, such as Figure 4 As shown, it includes the single-line prestressed assembled track beam in Embodiment 1, and several prefabricated floor slabs 6 are connected between two rows of single-line prestressed assembled track beams arranged in parallel to form a double-line prestressed assembled track beam. line area.

[0043] In the above embodiment, the cantilevered sides of the flange 111 are provided with rebates. During installation, the prefabricated floor 6 can be placed directly on the rebate 112, which solves the installation problem of the prefabricated floor 6 in the track area.

[0044] In addition, for multi-line track beams, it can be realized in the form of multiple pieces of track beam bodies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com