Metal support lug tapping processing device

A processing device and metal technology, which is applied in the field of parts processing devices, can solve problems such as insufficient use effect, low safety, and affecting the quality of equipment use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

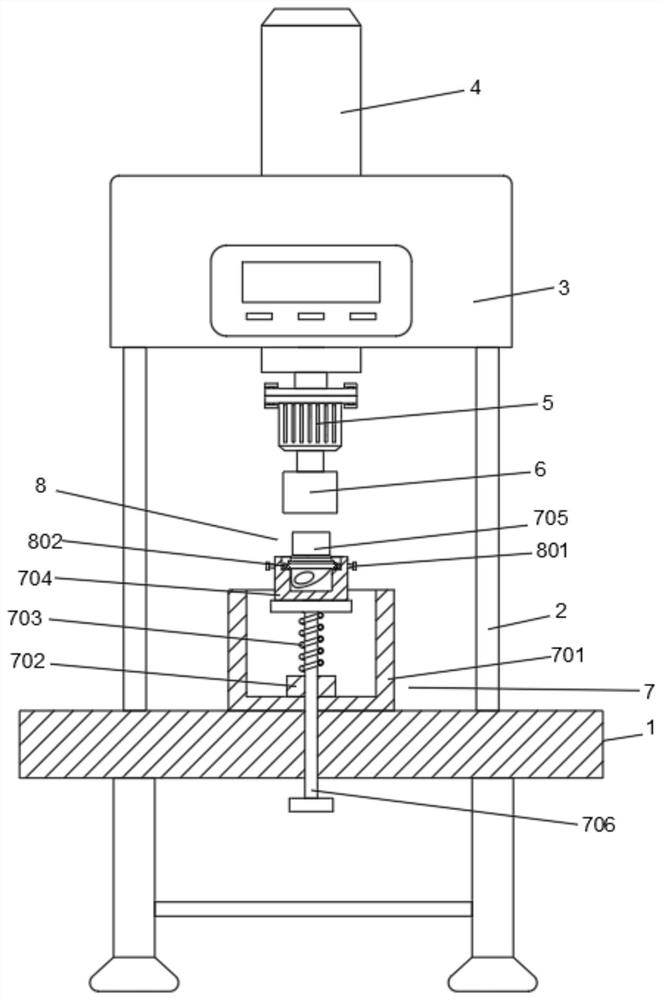

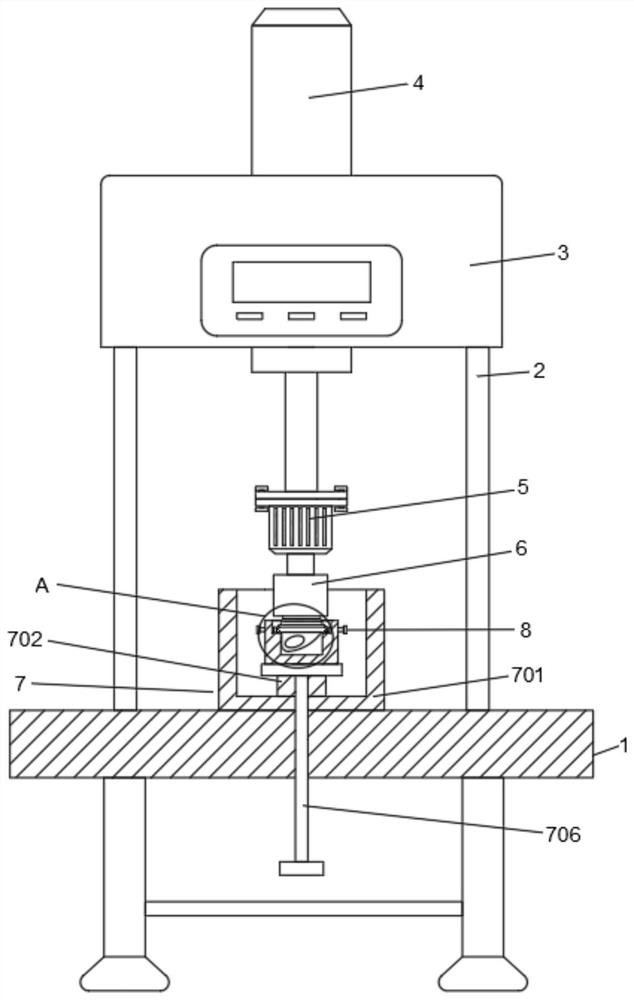

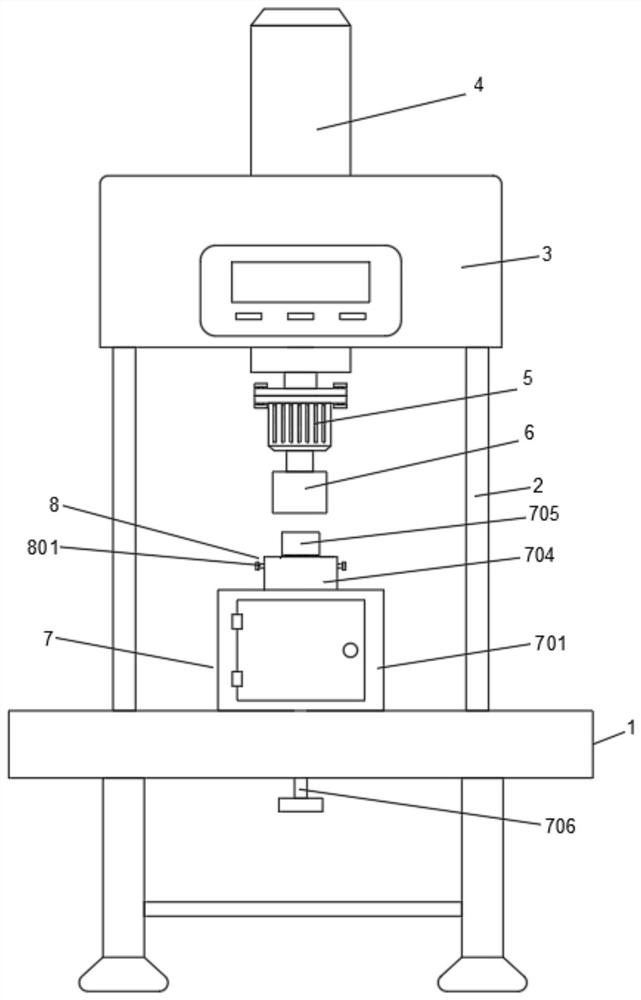

[0024] A metal lug tapping processing device, comprising a platform 1, a vertical support frame 2 is fixedly connected to the top of the platform 1, a body 3 is installed on the top of the support frame 2, a telescopic cylinder 4 is fixedly mounted on the top of the body 3, and the telescopic cylinder The telescopic end of 4 is fixedly connected with motor 5 positioned at the bottom of body 3 , the output end of motor 5 is fixedly connected with die 6 , the top of platform 1 is fixed with receiving mechanism 7 , and fixing mechanism 8 is arranged in receiving mechanism 7 .

[0025] In this embodiment, a controller is fixed on the outer wall of the body 3, and the output end of the controller is connected to the telescopic cylinder 4 and the motor 5. The model of the controller is KY02S, and the telescopic cylinder 4 and the motor 5 are controlled by the controller to improve Efficiency of equipment usage.

Embodiment 2

[0027] A metal lug tapping processing device, on the basis of Embodiment 1, the storage mechanism 7 includes a storage bin 701 installed on the top of the platform 1, a stable block 702 is fixed on the bottom inner wall of the storage bin 701, and the stability block 702 There is a vertically movable stopper 708 running through the inside, and a vertically movable limit rod 706 runs through the inside of the platform 1. The outer surface of the limit rod 706 is covered with a spring 703 located inside the storage bin 701. A fixed plate is fixed, and a placing bin 704 is fixed on the upper part of the fixing plate, and a spring 703 is connected between the fixing plate and the stabilizing block 702 , and a workpiece 705 is placed inside the placing bin 704 .

[0028] In this embodiment, the fixing mechanism 8 includes a threaded sleeve 803 installed on the storage bin 704. The internal thread of the threaded sleeve 803 is connected to a screw 801 in rotation, and the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com