Desulfurization method of coal

A technology for coal and raw coal, applied in solid separation and other directions, can solve problems such as difficult desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

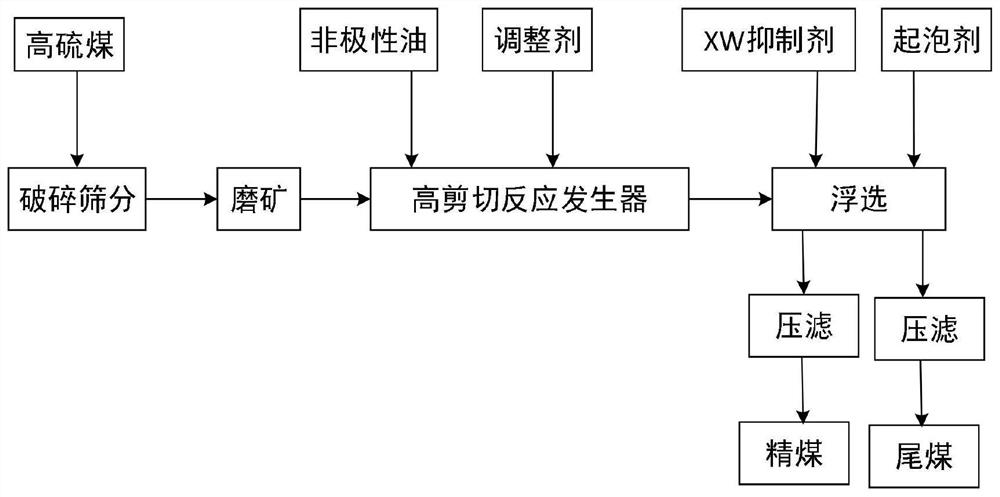

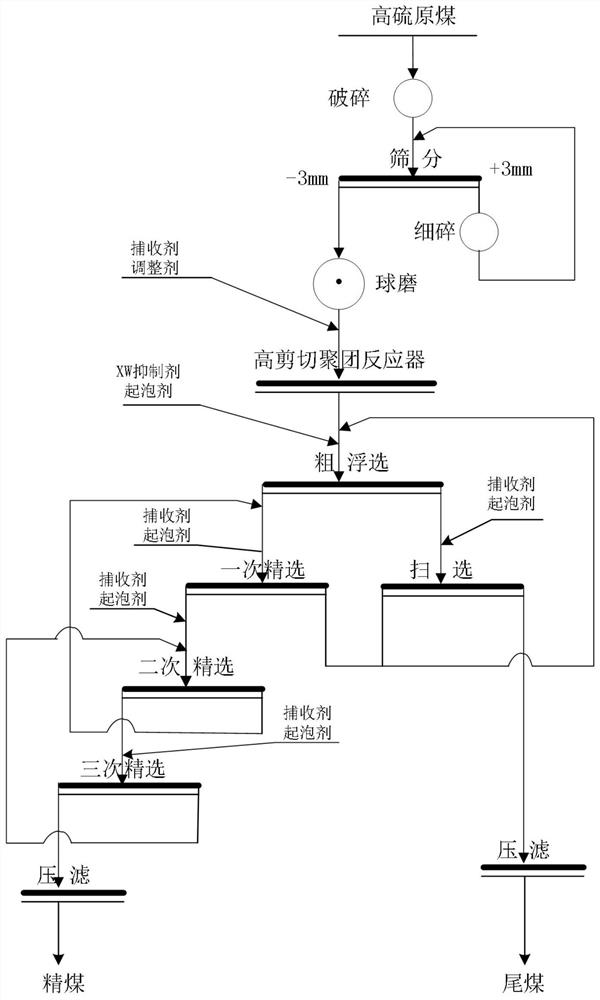

Method used

Image

Examples

Embodiment 1

[0079] A gas-fertilized coal contains 2.83wt% sulfur, and the particle size distribution of fine pyrite in the coal is shown in Table 1 under microscope observation.

[0080] Table 1 The particle size distribution of fine-grained pyrite in gas-fertilized coal

[0081] Distribution particle size <5μm

5~10μm 10~20μm 20~50μm >50μm percentage% 36.6 34.2 10.4 13.2 5.6

[0082] The coal is crushed and sieved and then ground to an average particle size of 30 microns or less. The flotation concentration is 8wt%, kerosene is added, the dosage is 1200g / t raw coal, and the rotating speed of the high-shear agglomeration generator is 35000rad / min for 15min, adding sodium bicarbonate and water to make the pH value of the coal slurry 8.2, at room temperature Stir at low temperature for 1 min, then temper the coal slurry, change the surface potential of the flotation coal particles and pyrite particles, and strengthen the hydrophobicity of the coal particl...

Embodiment 2

[0085] A certain coking coal in Shanxi contains 3.08wt% sulfur. The particle size distribution of fine pyrite in the coal is shown in Table 2 under microscope observation.

[0086] Table 2 The particle size distribution of fine-grained pyrite in coking coal

[0087] Distribution particle size <5μm

5~10μm 10~20μm 20~50μm >50μm percentage% 28.7 35.5 11.8 14.2 9.8

[0088] The coal is crushed and sieved and then ground to an average particle size below 40 microns. The flotation concentration is 8wt%, kerosene is added, the dosage is 1000g / t raw coal, and the speed of the high shear agglomeration generator is 35000rad / min for 15min, and sodium carbonate and water are added to make the pH value of the coal slurry 8.0. Stirring for 1min, tempering the coal slurry, changing the surface potential of the flotation coal particles and pyrite particles, and strengthening the hydrophobicity of the coal particles, so that the coal particles with natural ...

Embodiment 3

[0091] A certain coking coal in Inner Mongolia contains 3.21wt% sulfur, and the particle size distribution of fine-grained pyrite in the coal is shown in Table 3 under microscope observation.

[0092] Table 3 The particle size distribution of fine-grained pyrite in coking coal

[0093] Distribution particle size <5μm

5~10μm 10~20μm 20~50μm >50μm percentage% 12.6 27.8 41.8 11.5 6.3

[0094] The coal is crushed and sieved and then ground to an average particle size of less than 50 microns. The flotation concentration is 8wt%, diesel oil is added, the amount is 1400g / t raw coal is processed by high shear agglomeration generator at a speed of 35000rad / min for 15min, calcium oxide and water are added to make the pH value of the coal slurry at 8.1, at room temperature Stirring for 1min, tempering the coal slurry, changing the surface potential of the flotation coal particles and pyrite particles, and strengthening the hydrophobicity of the coal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com