Automatic lead wire adjusting device and method thereof

An automatic adjustment device and sliding adjustment technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of difficult to meet production needs, difficult alignment operation, low production efficiency, etc. The effect of skill level limitation, improvement of assembly efficiency and consistency, and high accuracy of alignment adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

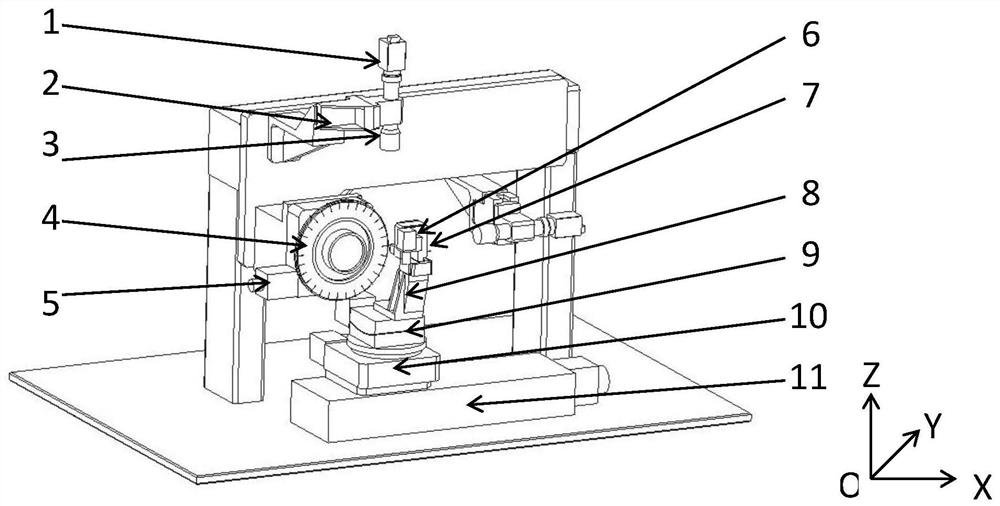

[0069] In this embodiment, an automatic adjustment device for lead wires of the present invention is used to automatically align the parts to be welded and the leads. The parts to be welded are brushes whose structure is known to those skilled in the art and are corner parts.

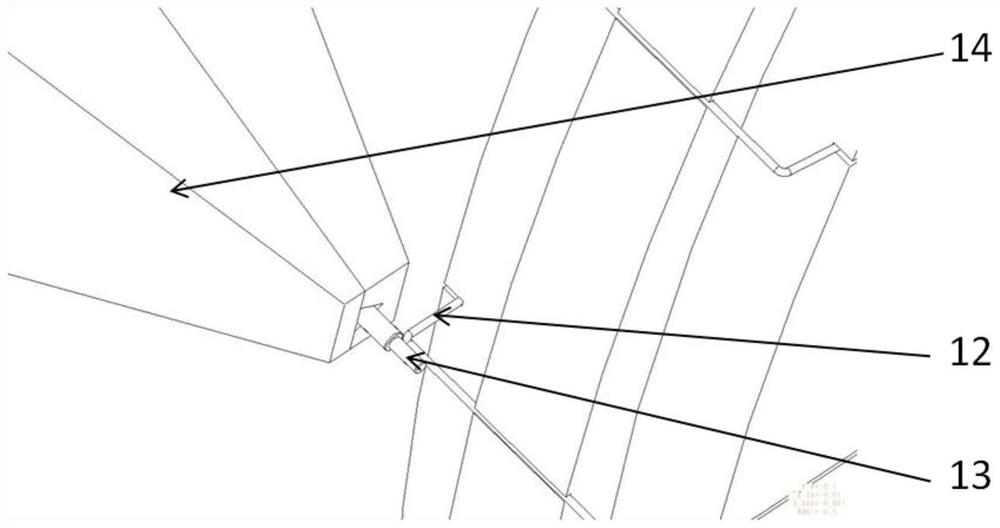

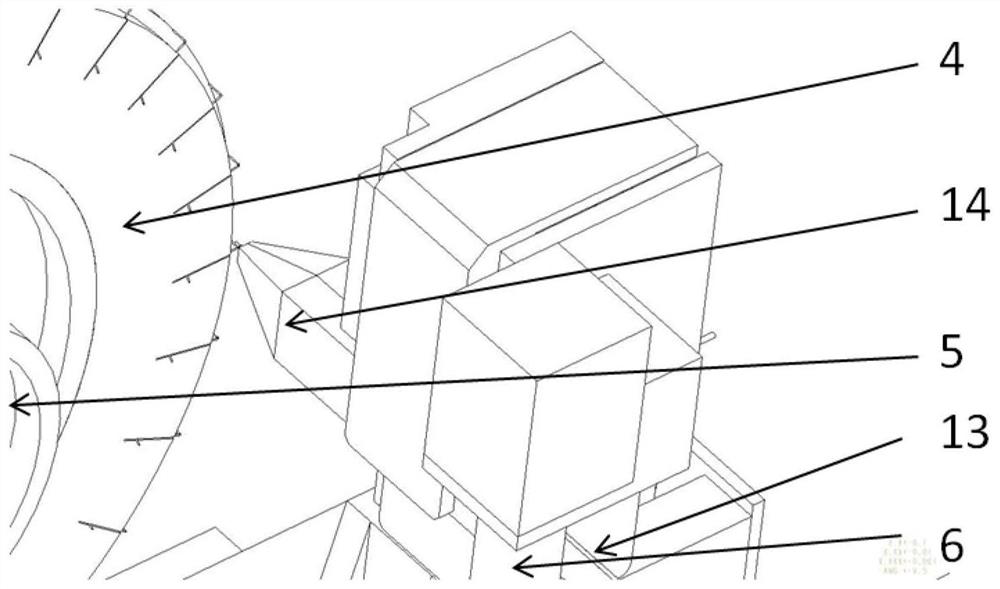

[0070] Such as Figure 4 As shown, the lead wire 13 is sent to the wire feeding nozzle 14 through the wire feeding roller 6. At this time, the photoelectric sensor 7 detects the lead wire, and outputs the detection result to the working condition control machine in the identification component, and the working condition control machine issues a length adjustment command to drive The wire feeding motor in the wire feeding assembly makes the wire feeding rollers continue to work until the lead wire 13 is sent out to a certain length to meet the welding requirements.

[0071] For the convenience of description, the origin of the coordinate system is set as the centroid of the slide base, the X-axis is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com