Automatic keyboard laminating equipment

A kind of laminating equipment and automatic technology, applied in the direction of mechanical equipment, material gluing, connecting components, etc., can solve the problems affecting the quality stability of semi-finished products, difficult to guarantee lamination accuracy, and high labor intensity, so as to reduce labor intensity and reduce labor costs. cost, improve production efficiency, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

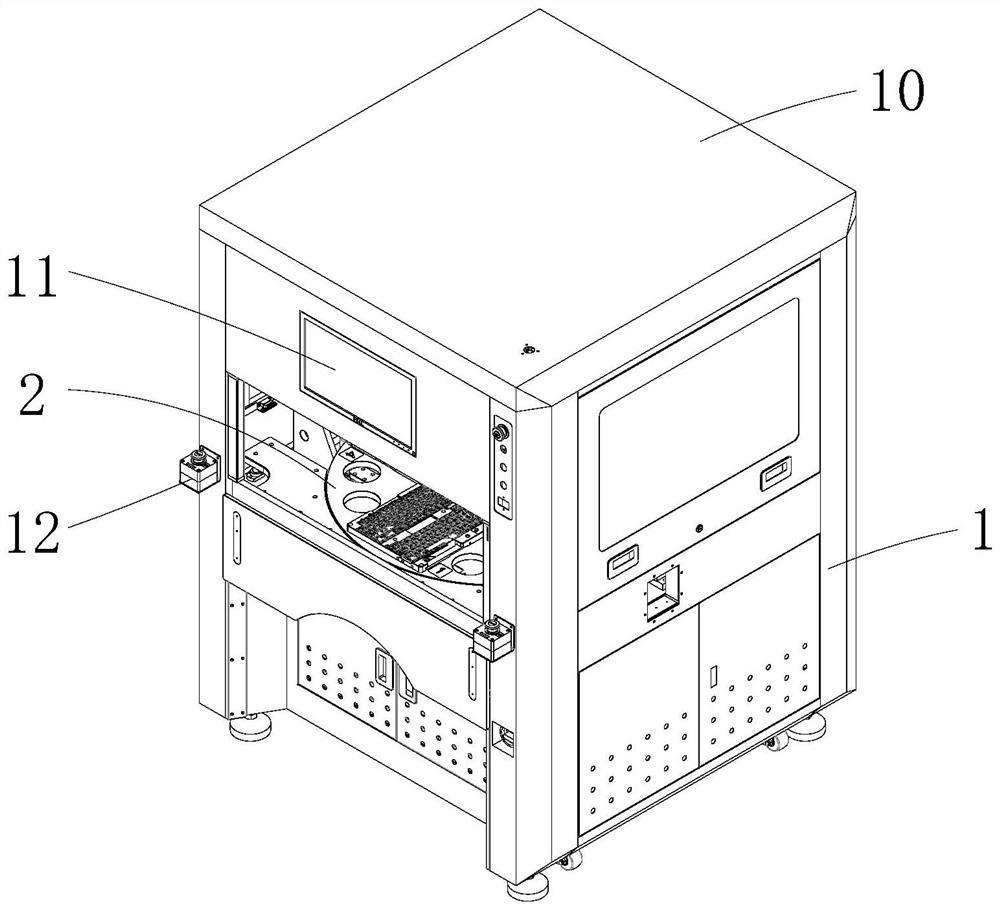

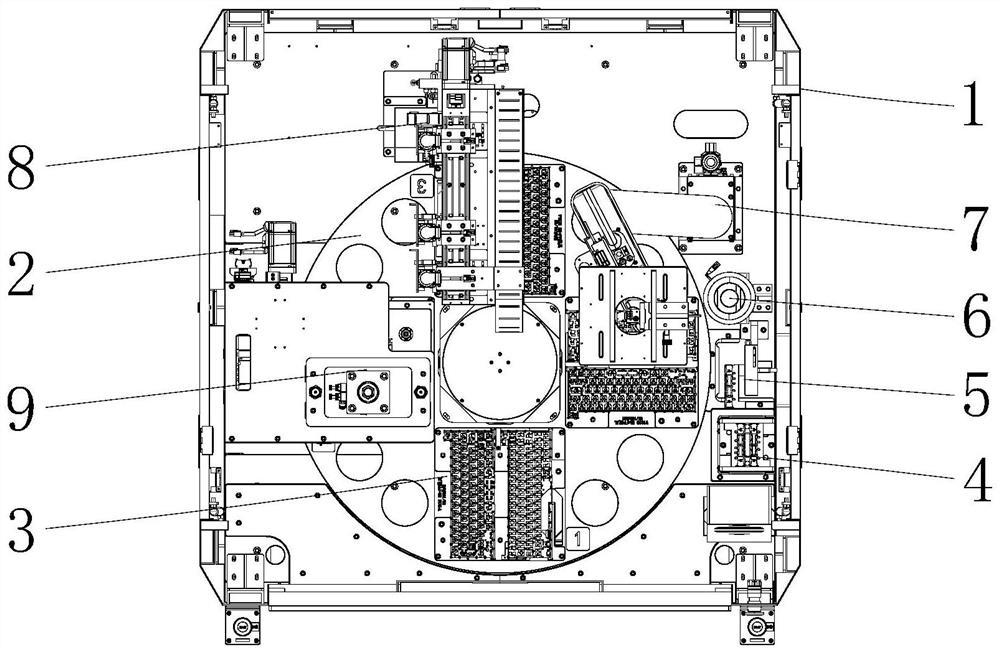

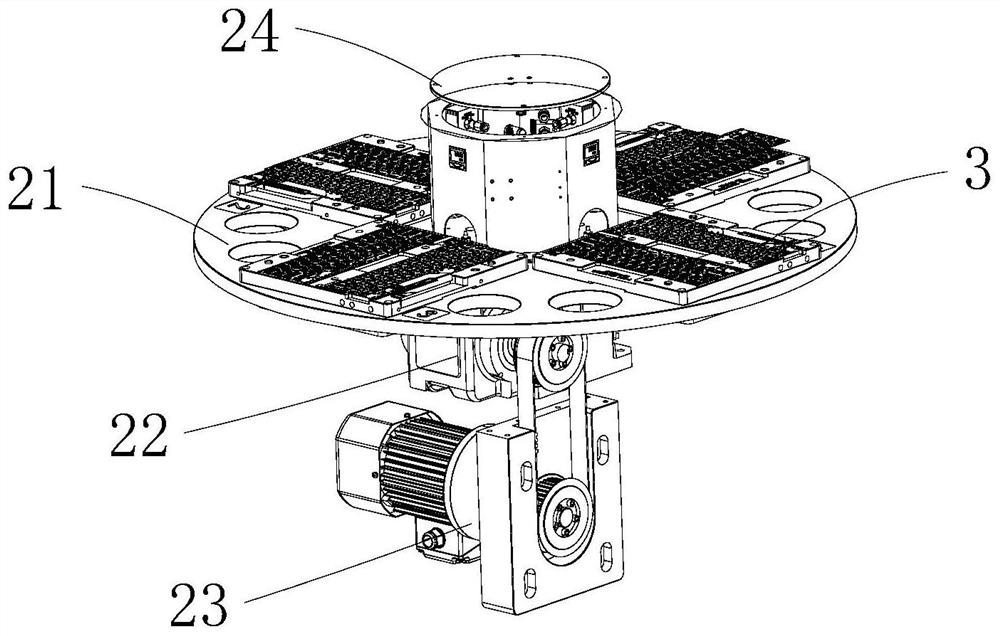

[0034] Such as Figure 1-2 As shown, the present embodiment provides a keyboard automatic bonding equipment, including a frame 1, the frame 1 is welded by an internal square tube frame and an external sheet metal shell, and the frame 1 is provided with a turntable component 2, The turntable part 2 is provided with a plurality of carriers 3 for placing substrates and circuit chips, and the outer circumference of the turntable part 2 is sequentially provided with a pressure-sensitive adhesive bin 4, a lower tearing film mechanism 5, a CCD alignment mechanism 6, Mechanical arm 7, upper film tearing mechanism 8 and transplanting pressing mechanism 9;

[0035] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com