Multifunctional engineering vehicle and accessory assembly reloading method thereof

An engineering vehicle and multi-functional technology, which is applied to vehicle parts, lifting devices, transportation and packaging, etc., can solve the problem of being unable to meet the needs of various working conditions, unable to meet the existing production and construction, and wasting the time and energy of operators, etc. problems, to achieve the effect of meeting the needs of multi-working conditions, saving replacement time, reducing production difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

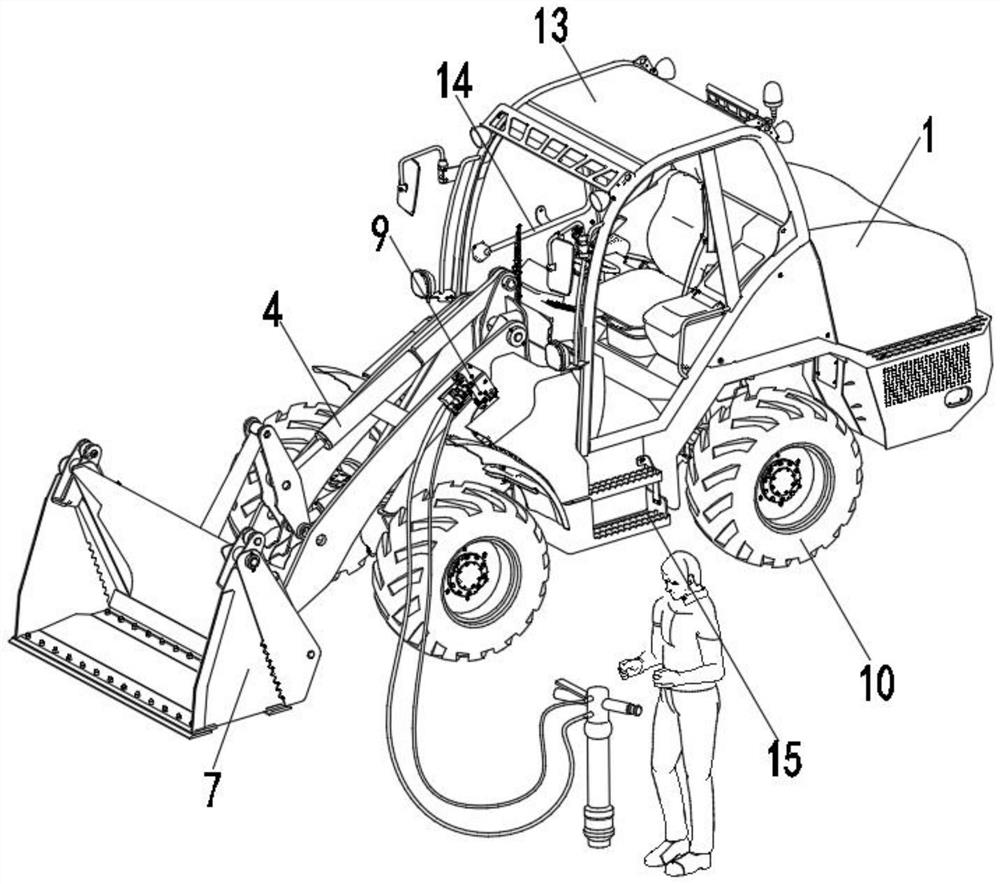

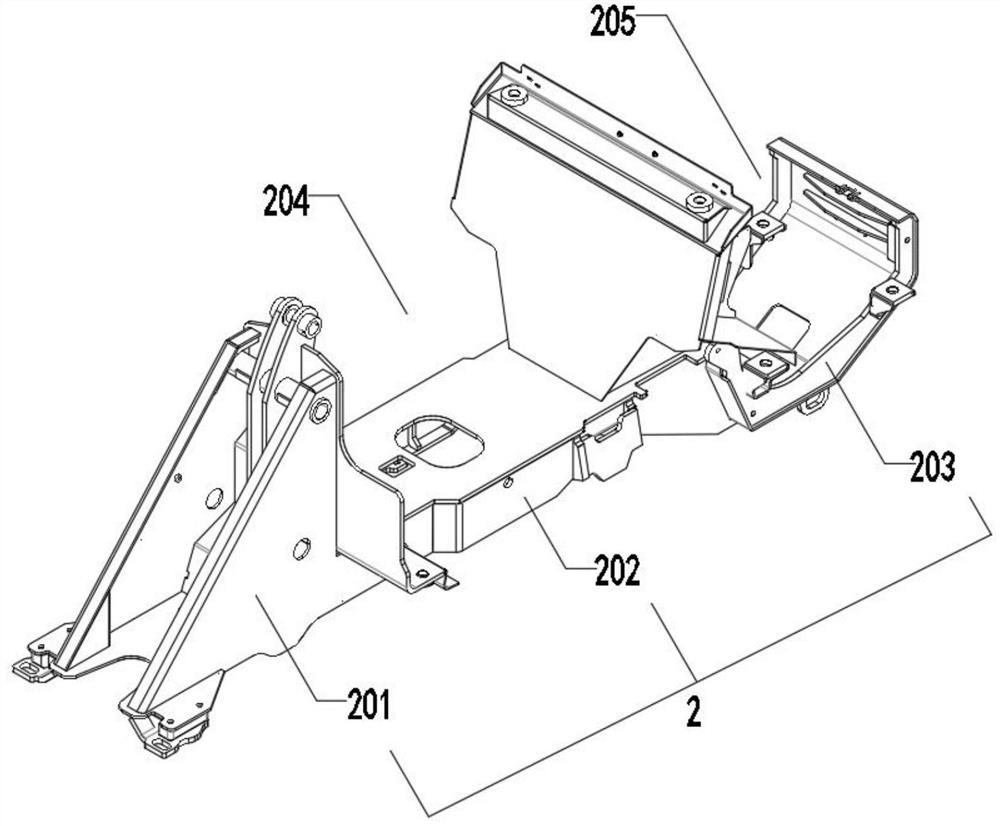

[0062] like figure 1 with figure 2 As shown, a multi-functional engineering vehicle includes a engineering vehicle body, the engineering vehicle body includes a body body 1 and a frame main body 2 connected thereto, and an end portion of the frame main body 2 is provided with a connecting structure 3, a connection structure 3 and one. One end of the power arm assembly is connected, and the other end of the power arm assembly is provided with the quick exchange device 6, and the attached attachment connection is connected to the attached attachment, and the attached gear is driven by the power arm assembly. The oil source module 9 is provided on the vehicle owner, and the oil source module 9 is used to drive other construction props and hydraulic tools, and the frame main body 2 is provided with a drive assembly 10 and a steering control system, and the drive assembly 10 is used to drive. The engineering vehicle body is moved, and the steering control system is used to control the ...

Embodiment 2

[0074] like Figure 9 As shown, the difference from the first embodiment is that the power arm assembly is set to telescopic arm assembly 5, which can be used for transportation or high-altitude operation; an assembly assembly 11 and a beam 12, assembly assembly 11 is provided on the attachment assembly 11. The assembly hole and assembly groove for mating with the quick exchange device 6 is opened, and the beam 12 is used to reinforce the accessory propagation, and can be used by the fitting assembly 11 and the quick exchange device 6, enabling aater and Quick disassembly and installation of the quick exchange device 6, by assembling the beam 12 on the accessory gear 12, can be reinforced with the attachment gear, improve its carrier capacity and service life, and can also be subsequently limited to prevent the use process Excessive lifting in the middle.

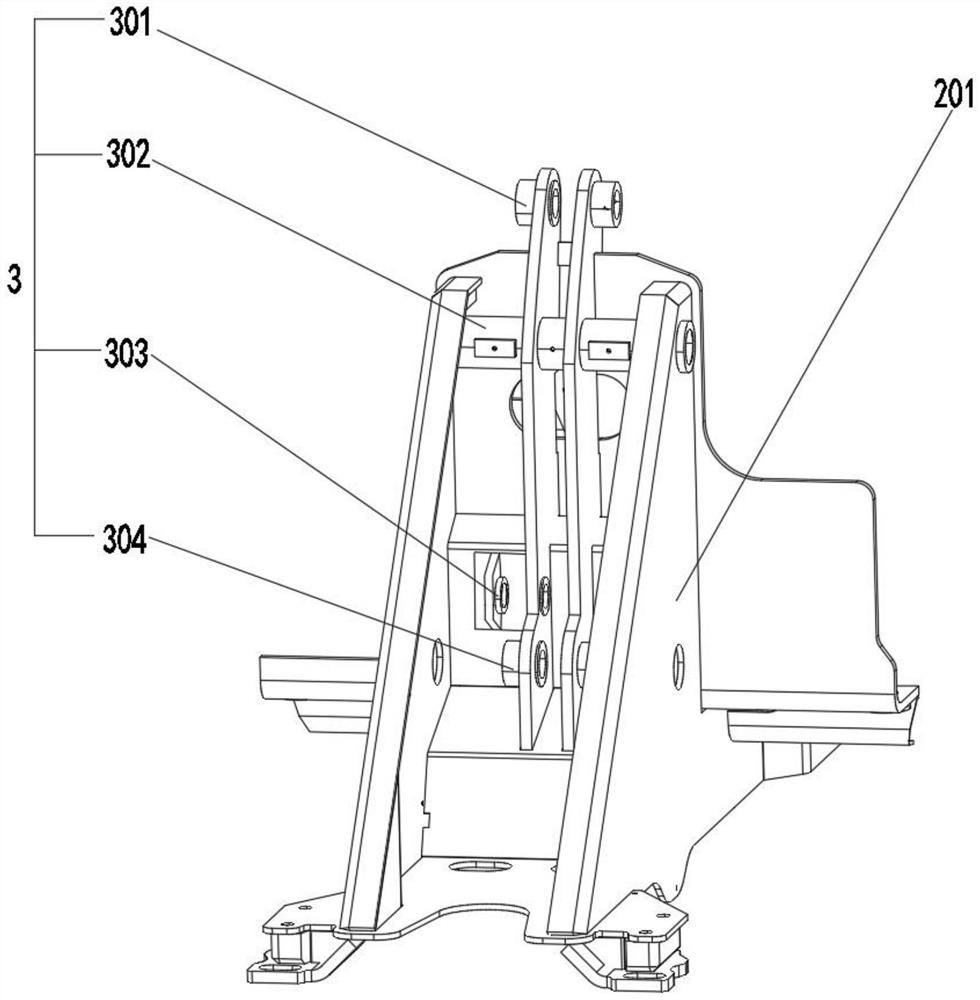

[0075] like image 3 with Figure 11 The connection structure 3 includes a connection structure 3 including a connecting structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com