Rotary drilling and dry drilling construction slag removal device

A technology for rotary drilling and rotary drilling, which is applied in the field of rotary drilling dry drilling construction slag cleaning devices, can solve the problems of unqualified pile formation quality, high cleaning difficulty, and fast slag formation speed of suspended sand particles. Achieve the effect of improving the integrity, ensuring the quality of the pile, and the installation process is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-3 The application is described in further detail.

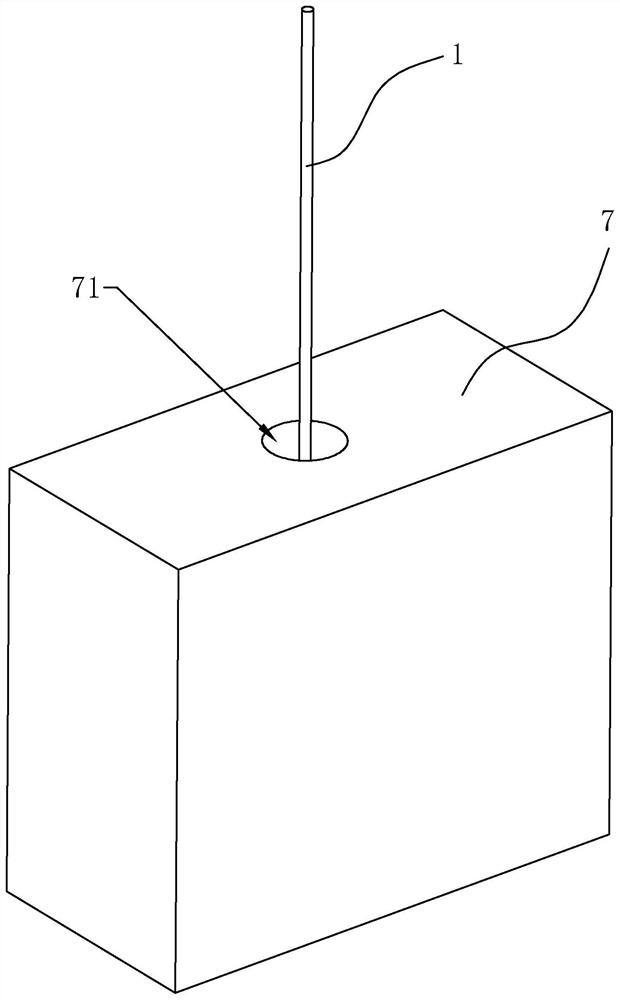

[0034] The embodiment of the present application discloses a slag removal device for rotary drilling and dry drilling. refer to figure 1Carry out the excavation of the foundation pit 71 on the ground 7, the foundation pit 71 to be excavated is vertically arranged, the space of the foundation pit 71 is a cylinder, and the excavation of each group of foundation pits 71 is carried out by means of a rotary excavator.

[0035] refer to figure 1 and figure 2 , the rotary excavator travels to the position on the ground 7 where the foundation pit 71 is to be excavated. At this time, the rotary excavator is equipped with a vertically arranged rotary drill rod 1. The rotary drill rod 1 is a cylinder. 1 is rotatably connected with the rotary drilling machine, and the vertical lower end of the rotary drilling rod 1 is equipped with blades 11 that are spirally distributed along the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com