Connection roadway type underground transfer sewage treatment system and construction method thereof

A sewage treatment system and connection lane technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve low work efficiency, increase labor intensity of workers, and water tank utilization Low efficiency and other problems, achieve the effect of low secondary discharge efficiency, good primary purification effect, and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

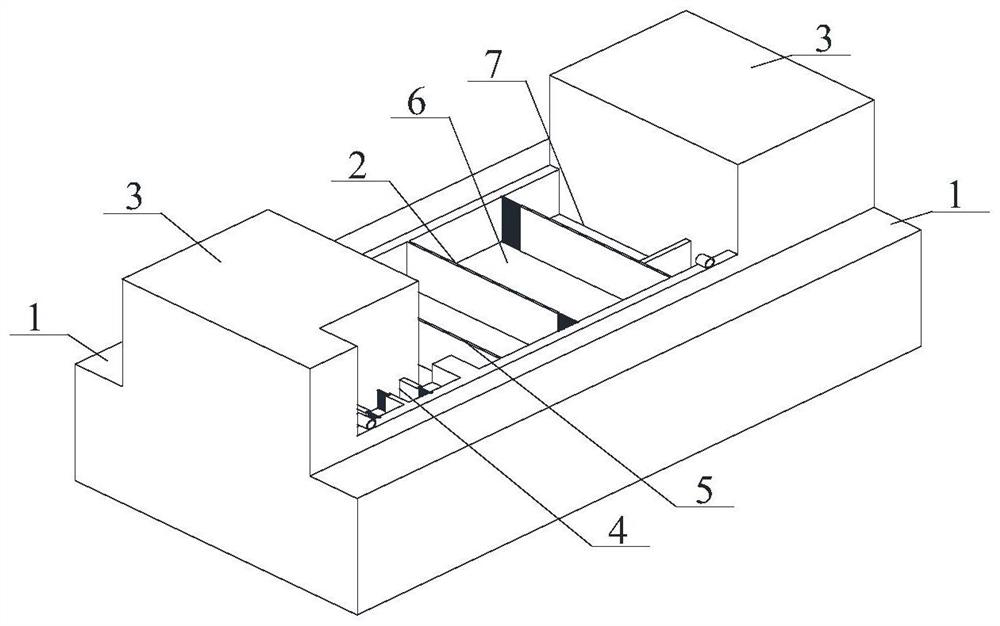

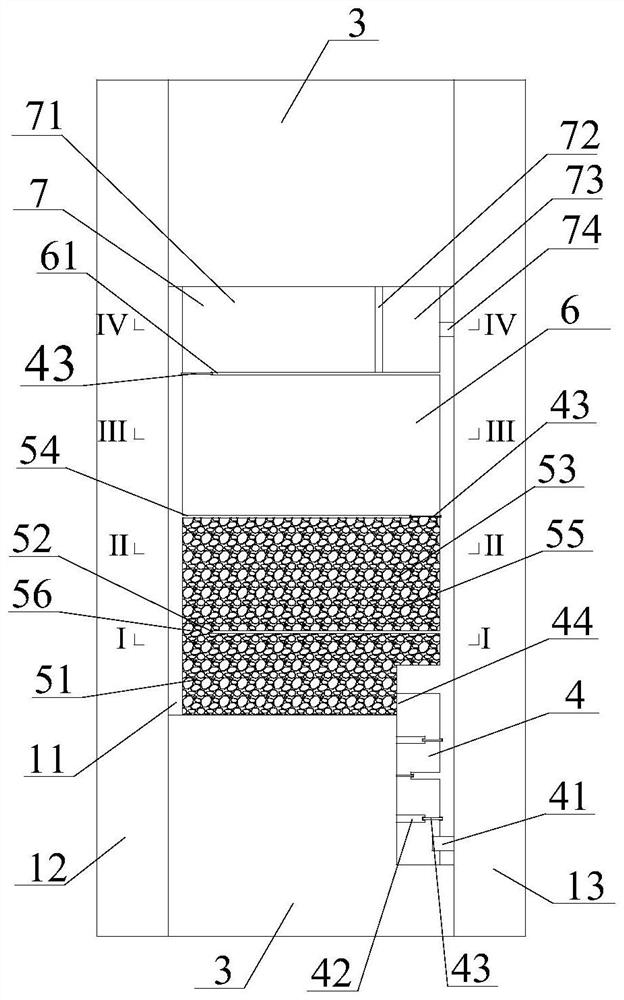

[0029] combine Figure 1 to Figure 8 As shown, the specific implementation of a connection lane type underground transfer sewage treatment system and its construction method provided by the present invention will be described.

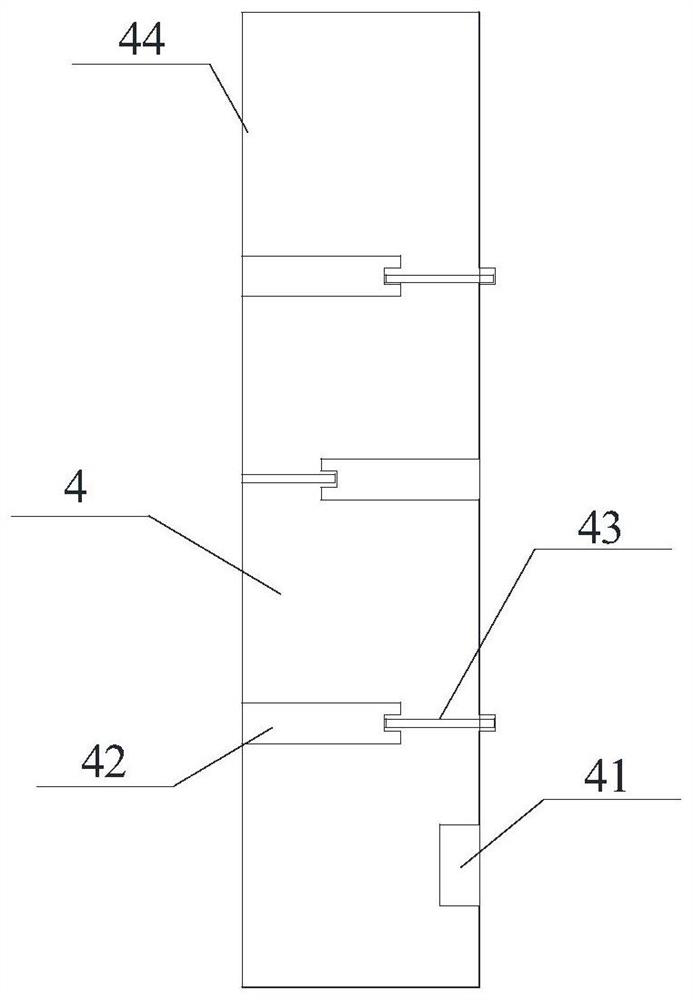

[0030] A connecting alley-type underground transfer sewage treatment system, including a roadway 1, a connecting alley 2, a coal pillar 3, a primary filter tank 4, a secondary filter tank 5, a sedimentation tank 6, a storage and drainage tank 7, a water injection pipe 41 and a drainage pipe 74. The primary filter tank 4 and the secondary filter tank 5 filter underground sewage in stages, and the sedimentation tank 6 and the storage and drainage tank 7 cooperate with each other to further complete the sewage filtration.

[0031] Wherein the primary filter pool 4 is arranged at the middle or lower part of the coal pillar side of the belt transport roadway, and communicates with the secondary filter pool 5 . The secondary filter tank 5 is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com