A vertical automatic casting cutting machine

A technology for cutting machines and castings, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of ground pollution, metal powder scattering, etc., and achieve the effect of convenient collection box, convenient movement and convenient sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

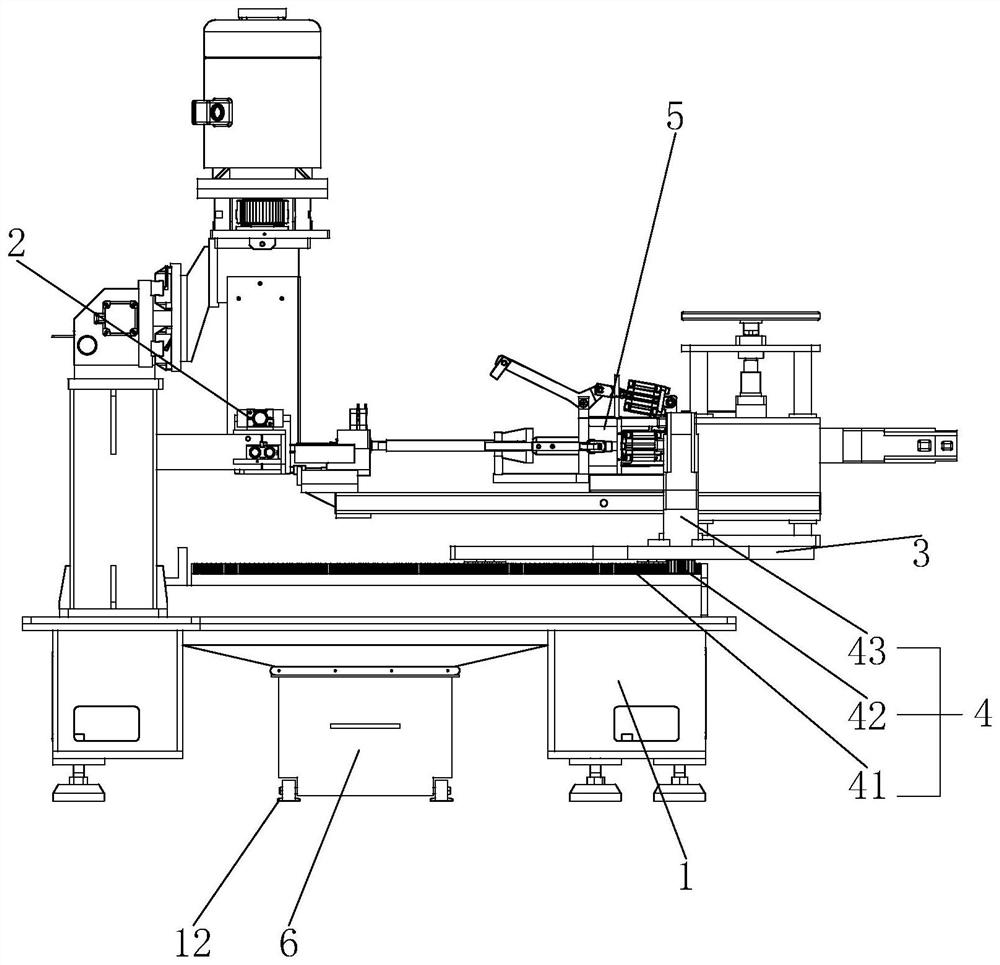

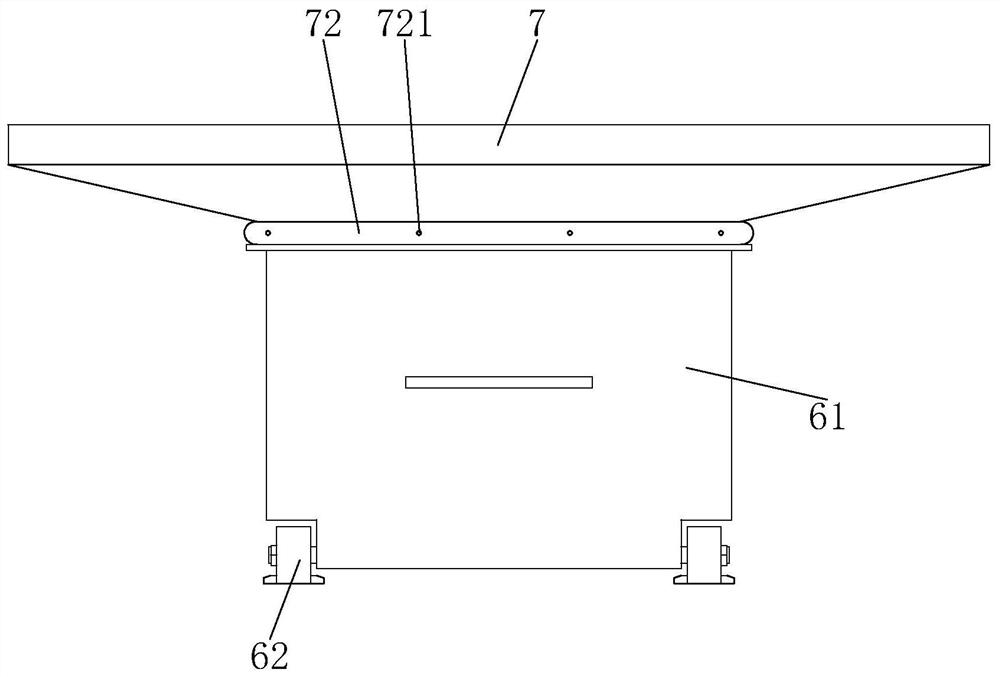

[0026] Example: a vertical automatic casting cutting machine, such as figure 1 As shown, it includes a machine tool 1, a cutting device 2 arranged at one end of the machine tool 1, a sliding table 3 slidably arranged at the other end of the machine tool 1, a driving mechanism 4 arranged between the machine tool 1 and the sliding table 3 and driving the sliding table 3 to move, The mold shell side bump holding device 5 is arranged on the sliding table 3 and is used for holding the mold shell, and the collecting device 6 is used for collecting the castings dropped after cutting. The driving mechanism 4 includes a rack 41 provided on the machine tool 1 and extending along the sliding direction of the slide table 3, a second reduction motor 42 provided on the slide table 3, and an output shaft of the second reduction motor 42 provided on the output shaft. The gear 43 with which the rack 41 meshes.

[0027] like Figure 1 to Figure 3 As shown, the machine tool 1 is fixedly provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com