A device and application of ultrasonic-assisted lost foam casting magnesium-aluminum bimetallic casting

A lost foam casting and ultrasonic-assisted technology, applied in the field of metal casting manufacturing, can solve the problems of poor process stability of lost foam casting solid-liquid composite technology, and achieve the effect of relieving the heating rate, strong effect, and promoting element diffusion.

Active Publication Date: 2022-05-31

HUAZHONG UNIV OF SCI & TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] In view of the above defects or improvement needs of the prior art, the present invention provides a method for ultrasonically assisted lost foam casting of magnesium-aluminum bimetallic castings. The role of impurity removal, thereby solving the technical problem of poor stability of the lost foam casting solid-liquid composite technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

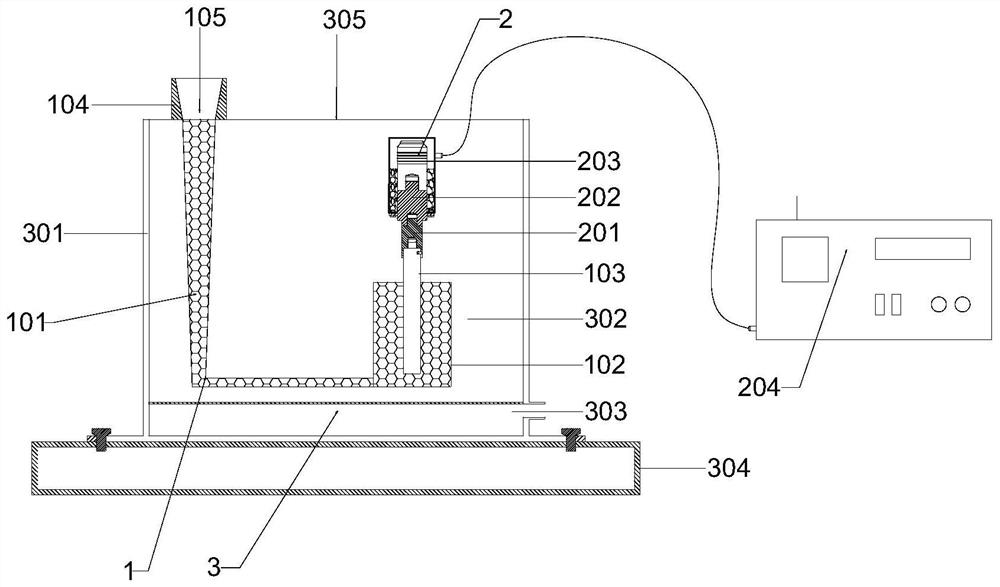

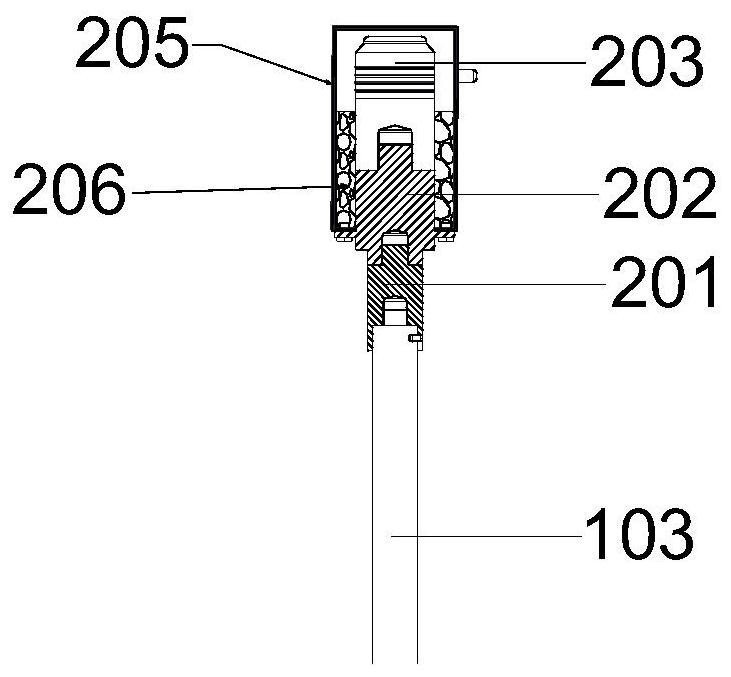

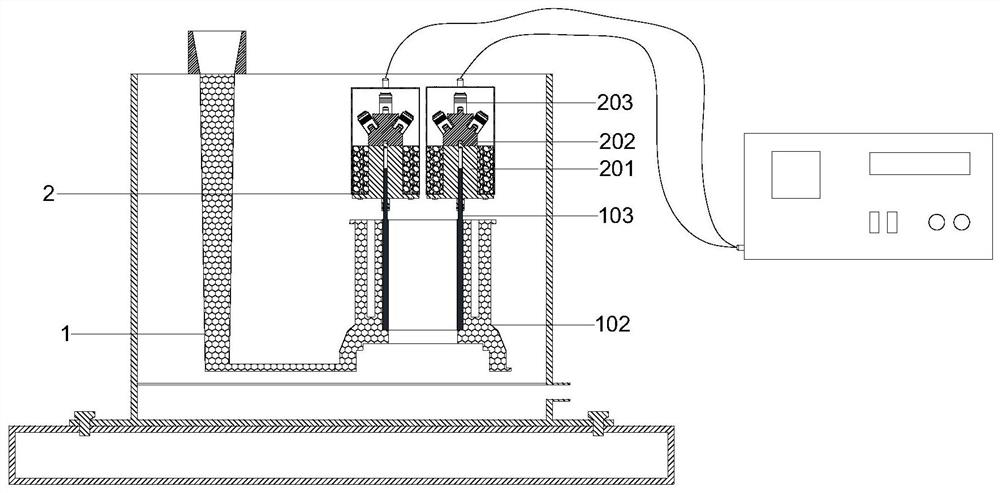

The invention belongs to the technical field of metal casting manufacturing, and in particular relates to a device and application of an ultrasonic-assisted lost foam casting magnesium-aluminum bimetallic casting. The ultrasonic-assisted lost foam casting magnesium-aluminum bimetallic casting device of the present invention comprises a lost foam casting composite model, an ultrasonic vibration component and a sand box, and the lost foam casting composite model includes a gating system, a casting model connected with the gating system, an embedded A solid inlay in the casting model; the ultrasonic vibration assembly includes a connector, a transducer holder detachably connected with the connector, an ultrasonic transducer detachably connected with the transducer holder, and an ultrasonic transducer Ultrasonic generators connected electrically. The invention can break and remove the oxide film on the surface of the aluminum inlay through the cavitation of the ultrasonic wave, eliminate the inclusion defect at the interface, and can also break the dendrites and refine the grains, thereby improving the quality of the magnesium-aluminum bimetallic material. organizational performance.

Description

A device and application for ultrasonic-assisted lost foam casting of magnesium-aluminum bimetallic castings technical field The invention belongs to the metal casting manufacturing technical field, be specifically related to a kind of ultrasonic-assisted lost foam casting magnesium-aluminum double Apparatus and application of metal castings. Background technique [0002] With the rapid development of modern industry, the fields of automobiles, weaponry and aerospace have become more and more Structural integration and comprehensive performance have put forward higher and higher requirements, and the use of a single material has become more and more difficult to meet the Due to the increasingly high requirements of the comprehensive performance of parts. Preparation of magnesium-aluminum bimetallic materials by compounding magnesium alloys and aluminum alloys and Parts, which can combine the advantages of magnesium alloy and aluminum alloy, realize the complementarity...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22C9/04B22D19/16B22D27/08

CPCB22C9/04B22D19/16B22D27/08

Inventor 蒋文明管峰王俊龙李广宇张政樊自田

Owner HUAZHONG UNIV OF SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com