Multi-stage micro-net screening and cleaning system and method for sludge impurities

A cleaning system and impurity technology, applied in cleaning methods and appliances, cleaning methods using liquids, sludge treatment, etc., can solve the problem of sludge reduction or reflux treatment, impurities that cannot be treated as domestic waste, and effective disposal and other problems, to achieve the effect of reducing cleaning and maintenance workload, facilitating collection and transportation, and easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

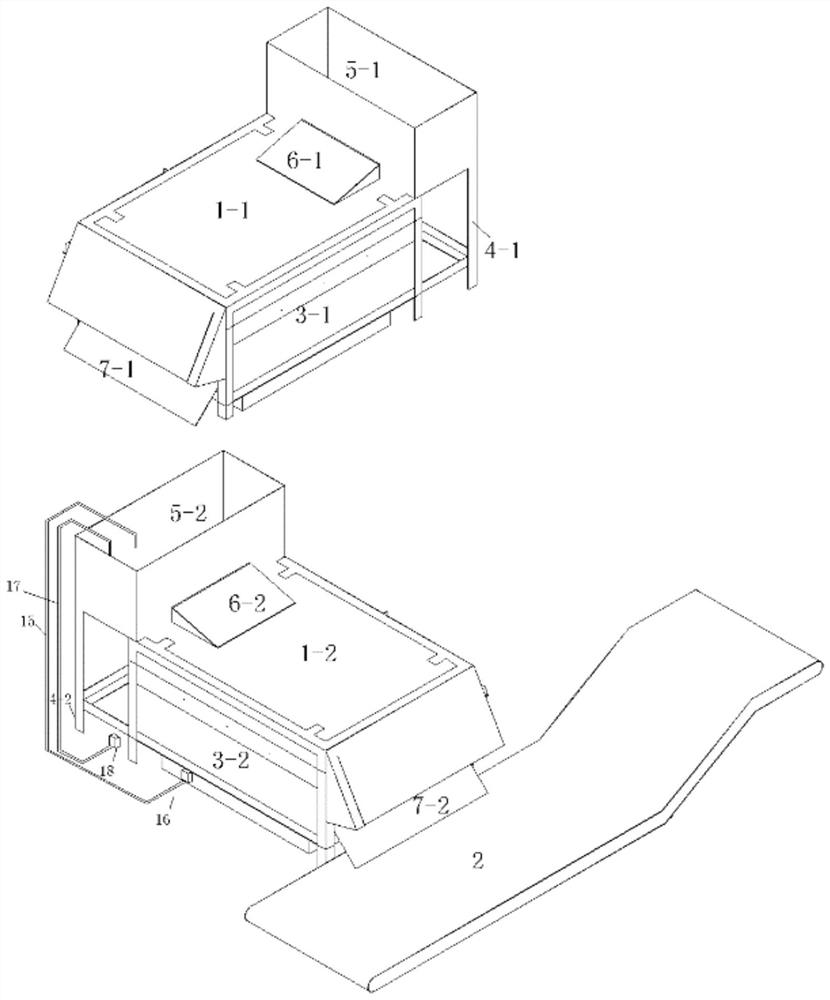

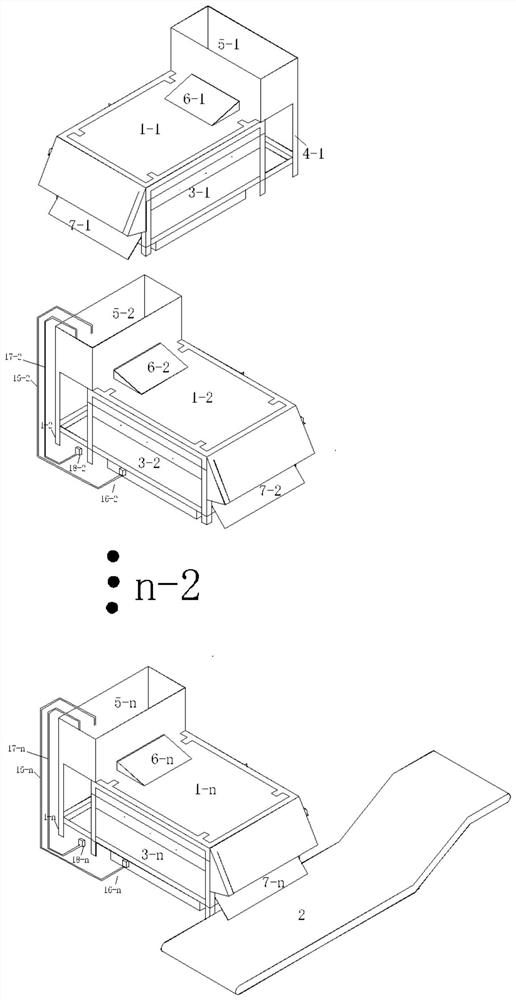

[0045] Such as Figure 1-2 As shown, it is a sludge impurity multi-stage micro-mesh screening and cleaning system provided in Example 1. The system consists of a primary impurity screening device 1-1, a primary impurity cleaning device, and a sieved sludge collection device 3- 1. Multiple secondary impurity screening devices 1-2, impurity collection device 2 and cleaning water recycling device 3-2; figure 2 As shown, there can be n secondary impurity screening devices 1-2, and then the sludge obtained by screening the primary impurity screening device 1-1 can be subjected to multiple secondary impurity screening, and then the sludge in the sludge The impurities should not be left as far as possible, which ensures the screening effect.

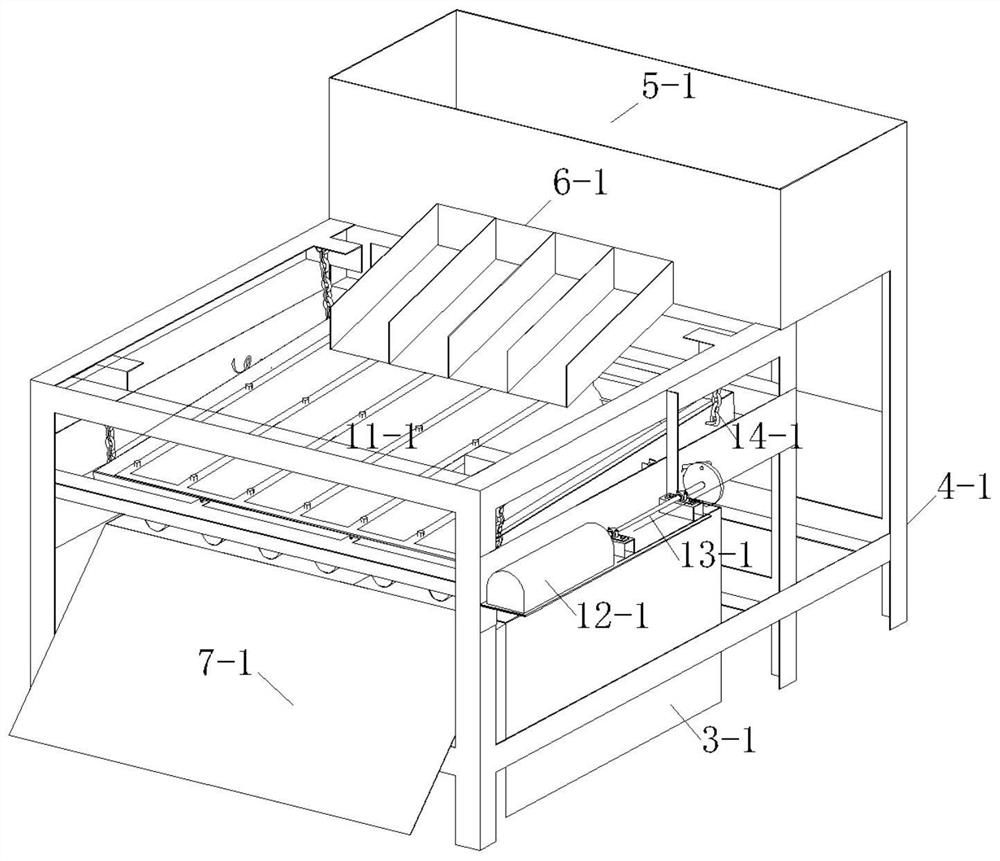

[0046] Such as image 3 As shown, the primary impurity screening device consists of a primary frame 4-1, a primary water inlet channel 5-1, a primary inclined trough 6-1, a primary inclined plate 7-1, and a primary impurity screening device ...

Embodiment 2

[0059] This embodiment provides a method for screening and cleaning sludge impurities using the system provided in Embodiment 1, which includes the following steps:

[0060] 1) The sludge passes through the water inlet channel 5-1, and finally enters the primary impurity screening device 1-1 through the inclined launder 6-1, and performs primary screening in the U-shaped channel 11-1 of the primary impurity screening device. The transmission shaft 13-1 is powered by the primary motor 12-1, and drives the primary screen frame 9-1 and the primary The screen 8-1 reciprocates horizontally along the vertical section of the U-shaped channel 11-1 of the primary impurity screening device. The flocs condense into rod-shaped impurity clusters with poor stability due to cohesion, and continue to adhere to other impurities on the moving path. They slide freely along the U-shaped channel 11-1 of the primary impurity screening device, and enter the The screened sludge collection device 3-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com