Preparation method of solid-phase extraction agent that can be used for plutonium separation

A solid-phase extraction agent and extraction technology, which is applied in the direction of improving process efficiency, can solve the problem of low plutonium separation efficiency, and achieve the effects of fast extraction rate, good selectivity, and large extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: Separation / recovery of plutonium in plutonium-containing waste liquid

[0018] 1) Preparation of extractant:

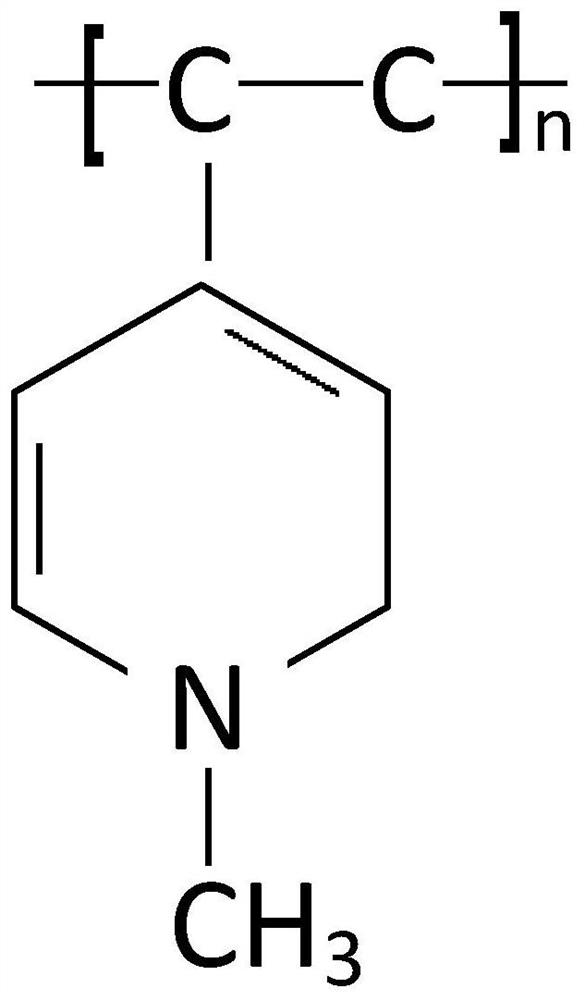

[0019] Weigh 3 g of polyvinylpyridine particles (2% cross-linked 60 mesh 8meq / g) into a 500 mL flask, add 100 mL of iodomethane (analytical grade), and then stir and react at 40 °C for 2 h. After the reaction product was nearly dried by rotary evaporation, it was washed with deionized water for more than 3 times, and dried for later use.

[0020] 2) Extraction and stripping of plutonium

[0021] Adjust the plutonium-containing waste liquid to a nitric acid concentration of 8-10 mol / L, add the synthesized solid-phase extraction agent at 10 mg extractant / 3 ml waste liquid, and stir or shake for 30 minutes. Centrifuge solid-liquid separation. Add 0.2 mol / L disodium EDTA at a ratio of about 10ml of stripping agent per gram of extractant, strip for 20 minutes, centrifuge for solid-liquid separation, and collect the stripped solution enriched in plutonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com