Lithium battery silicon carbon anode material processing equipment and processing method thereof convenient for grinding

A technology for negative electrode materials and processing equipment, which is applied in lithium battery silicon-carbon negative electrode material processing equipment and its processing field. It can solve the problems that processing equipment does not meet the crushing requirements, large particle raw materials are mixed in, and the grinding fineness is not high, so as to improve crushing. And the effect of grinding, improving efficiency, improving the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

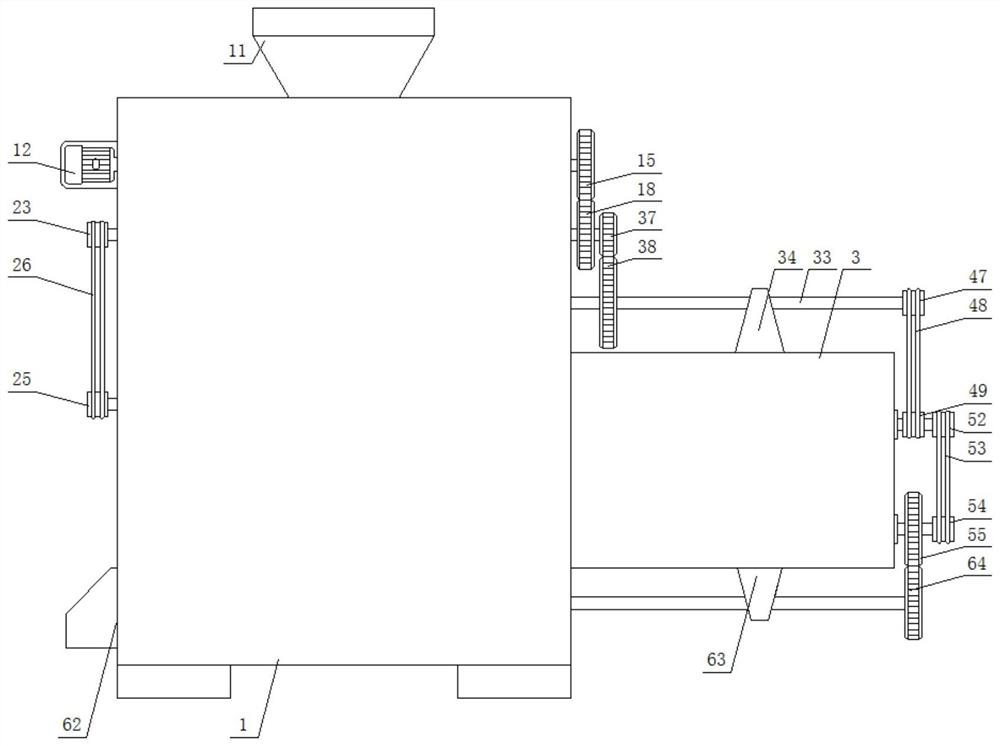

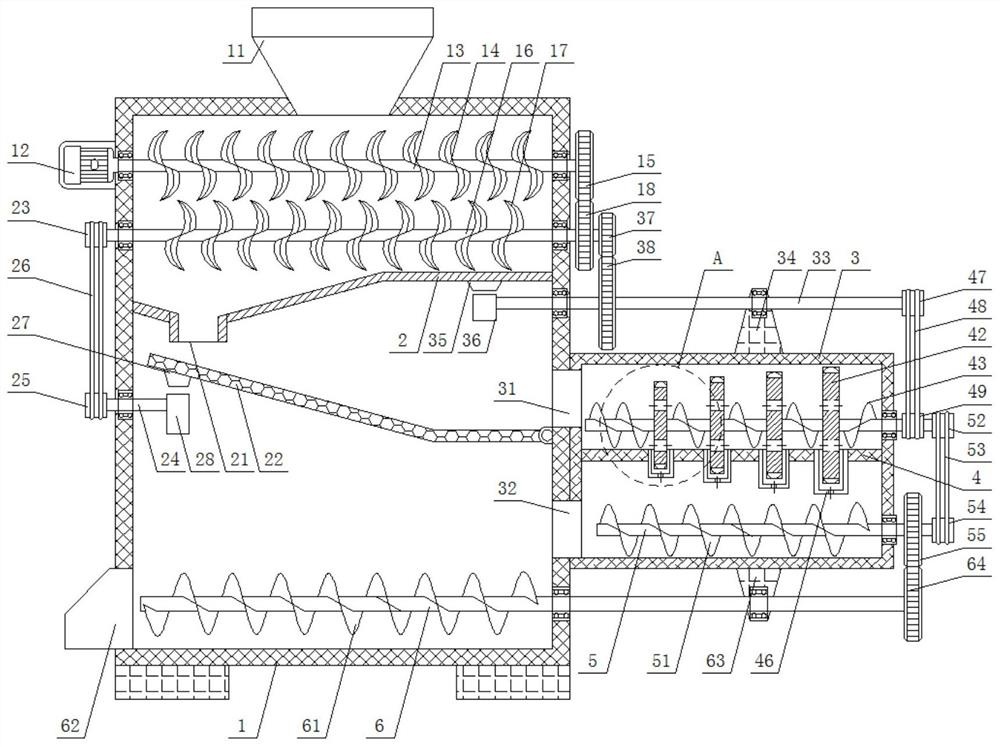

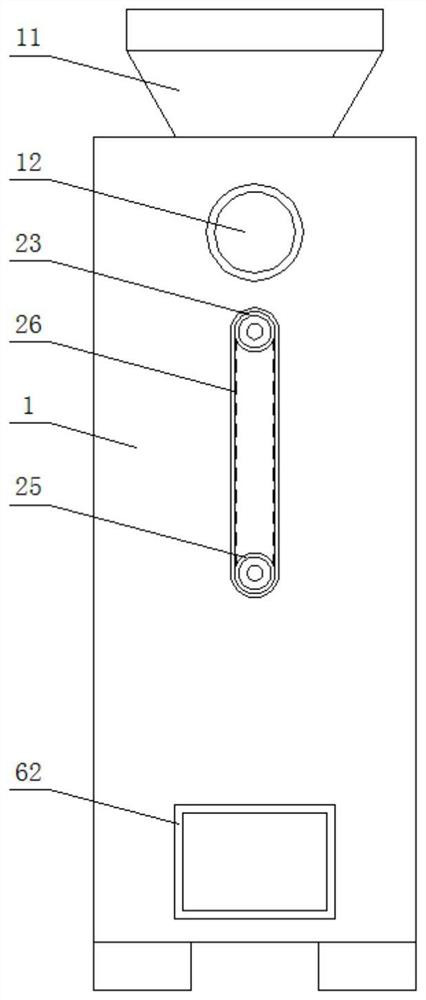

[0035] Embodiment 1: This embodiment provides lithium battery silicon carbon anode material processing equipment that is easy to grind, see Figure 1-5 Specifically, it includes a bottom box 1, a crushing mechanism, a vibrating screen component, a grinding mechanism, and a discharging component. The bottom box 1 is a rectangular box placed horizontally and vertically. Hopper 11, the inner top of the bottom box 1 is provided with a clapboard 2 which is fixed obliquely, a pulverizing mechanism is located on the top of the bottom box 1 located above the partition plate 2, and a crushing mechanism is located below the partition plate 2 in the middle of the bottom box 1. There is a vibrating screen assembly; the right side of the bottom box 1 is provided with a horizontally fixed grinding box 3, the middle of the grinding box 3 is provided with a horizontally fixed horizontal plate 4, and is located above the horizontal plate 4. In the grinding box 3, there is a For the grinding me...

Embodiment 2

[0041] Embodiment 2: In Embodiment 1, there is also the problem of inconvenient discharge of raw materials after pulverization and grinding. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0042] In the present invention, a first feeding shaft 5 placed laterally is arranged in the grinding box 3 under the horizontal plate 4 , and the right end of the first feeding shaft 5 is rotatably connected with the grinding box 3 and extends through the grinding box 3 . On the outside, in the grinding box 3, there are several first spiral blades 51 which are continuously screwed and fixed on the first feeding shaft 5. The right end of the first feeding shaft 5 is sleeved with a third driven pulley 54, which is located in the second feeding shaft 5. The outer side of the driving pulley 49 is sleeved with a third driving pulley 52 at the right end of the grinding shaft 41, and the third driving pulley 52 is connected with the third driven pulley 54 through the third...

Embodiment 3

[0044] Example 3: see Image 6 , in the present embodiment, the present invention also proposes a processing method of the lithium battery silicon carbon negative electrode material processing equipment that is convenient for grinding, including the following steps:

[0045] Step 1, add raw materials into the bottom box 1 through the feeding hopper 11, start the servo motor 12, control the motor shaft of the servo motor 12 to drive the first crushing shaft 13 and the first driving gear 15 to rotate synchronously, and drive the first driven gear through meshing. The gear 18 and the second pulverizing shaft 16 rotate in the reverse direction, thereby driving the first pulverizing reamer 14 to rotate in the forward direction and the second pulverizing reamer 17 to rotate in the reverse direction. Use, to pulverize the raw materials;

[0046] In step 2, the pulverized raw material falls onto the vibrating screen plate 22 along the partition plate 2 and the communication cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com