Positive electrode material as well as preparation method and application thereof

A positive electrode material and positive electrode technology, applied in the field of positive electrode and lithium ion battery, positive electrode material, and its low-temperature synthesis, can solve the problems of limited performance improvement of high-nickel materials, segregation of transition metal elements, and impact on discharge capacity, etc., to reduce the occurrence of side reactions , short cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

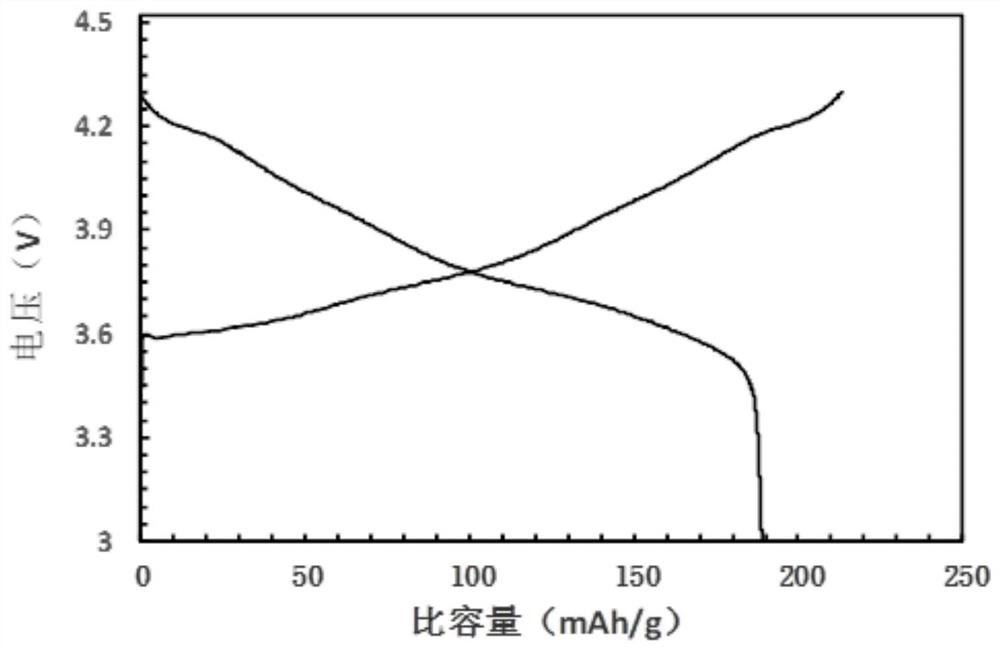

Embodiment 1

[0044] This embodiment provides a positive electrode material, including a zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material and Co on its surface. 2 B layer, the zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material and Co x The mass ratio of the B layer is 1:0.006.

[0045] This embodiment also provides a method for preparing the above-mentioned positive electrode material, comprising the following steps:

[0046] (1) Nickel cobalt manganese aluminum hydroxide, LiOH and ZrO 2 Dry mixed in a mixer, calcined the dry mixed material in an ordinary box furnace at 850°C in an oxygen atmosphere for 8 hours, cooled, crushed and sieved to obtain a zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material ;

[0047] Wherein, the molar ratio of each element in nickel-cobalt-manganese-aluminum hydroxide is Ni:Co:Mn:Al=83:8:6:3, Li / (Ni+Co+Mn+Al) molar ratio=1.025:1, Nicke...

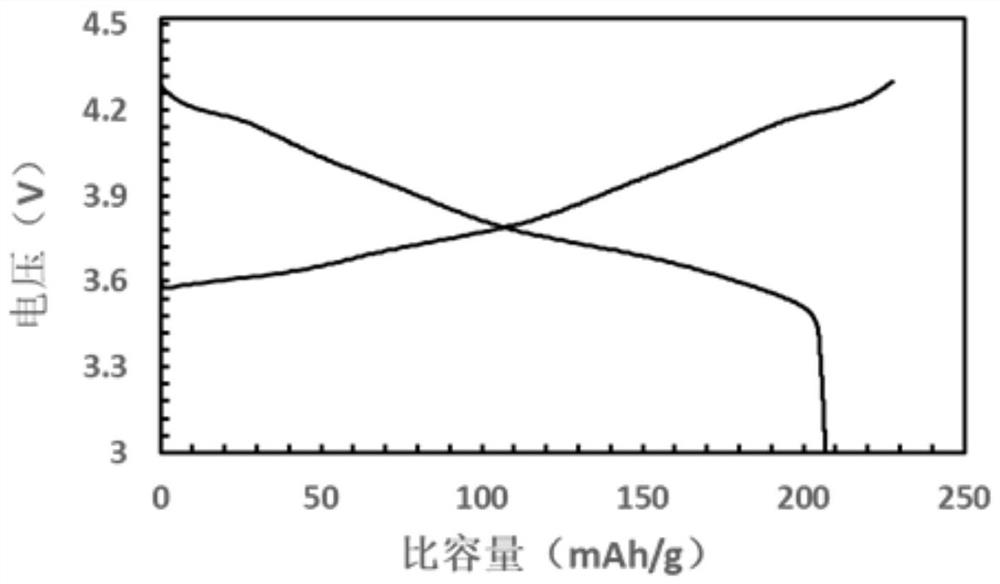

Embodiment 2

[0050] This embodiment provides a positive electrode material, including a zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material and Co on its surface. 2 B layer, the zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material and Co x The mass ratio of the B layer is 1:0.007.

[0051] This embodiment also provides a method for preparing the above-mentioned positive electrode material, comprising the following steps:

[0052] (1) Nickel cobalt manganese aluminum hydroxide, LiOH and ZrO 2 Dry mixed in a mixer, calcined the dry mixed material in an ordinary box furnace at 800°C in an oxygen atmosphere for 10 hours, cooled, pulverized and sieved to obtain a zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material ;

[0053] Wherein, the molar ratio of each element in nickel-cobalt-manganese-aluminum hydroxide is Ni:Co:Mn:Al=83:8:6:3, Li / (Ni+Co+Mn+Al) molar ratio=1.1:1, Nic...

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is that the zirconium-doped nickel-cobalt-manganese-aluminum single crystal positive electrode material and Co x The mass ratio of the B layer is 1:0.001.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com