Display panel and preparation method thereof

A display panel and longitudinal cross-section technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of color shift and impure luminescence, and achieve the effect of preventing color shift and improving luminous purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

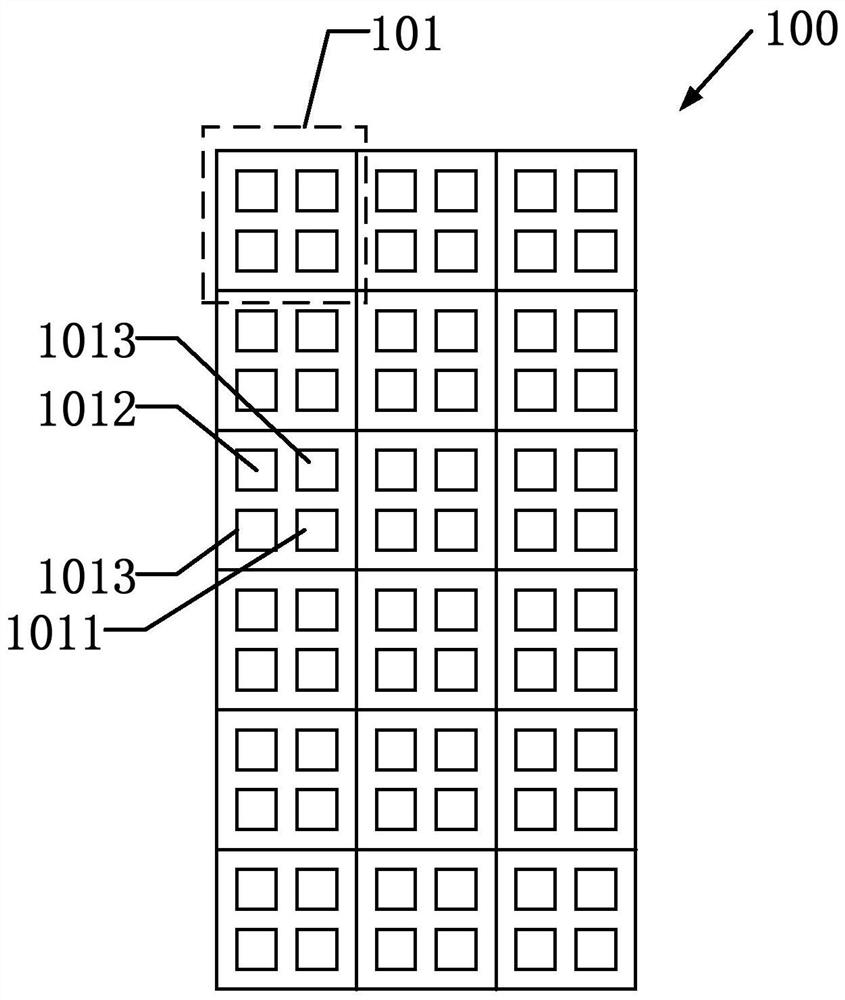

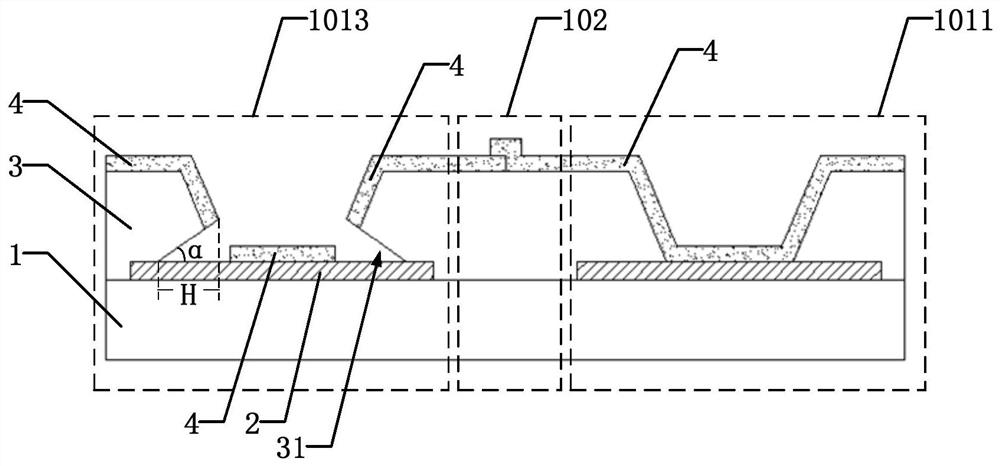

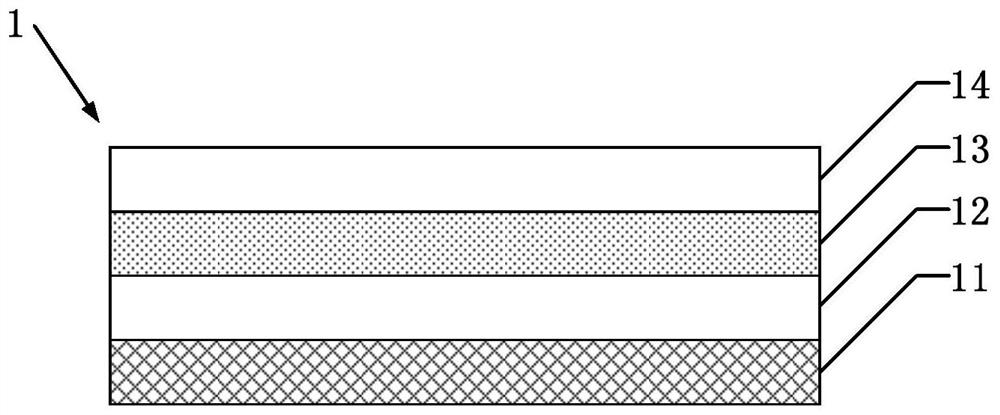

[0046] Such as figure 1 , figure 2As shown, this embodiment provides a display panel 100 . The display panel 100 includes a plurality of pixel units 101 arranged in an array. Each pixel unit 101 includes a plurality of sub-pixels. In this embodiment, each pixel unit 101 includes: a first sub-pixel 1011 , a second sub-pixel 1012 and two third sub-pixels 1013 . More preferably, in this embodiment, the first sub-pixel 1011 is a red sub-pixel, the second sub-pixel 1012 is a blue sub-pixel, and the third sub-pixel 1013 is a green sub-pixel. Wherein, the first sub-pixel 1011 is located at the lower right corner of the pixel unit 101, the second sub-pixel 1012 is located at the upper left corner of the pixel unit 101, and the two third sub-pixels 1013 are respectively located at the pixel unit 101 the lower left and upper right corners of the . In other embodiments, the colors of the first sub-pixel 1011, the second sub-pixel 1012, and the third sub-pixel 1013 can be replaced a...

Embodiment 2

[0062] Such as Figure 8 As shown, this embodiment includes most of the technical features of Embodiment 1, and its difference from Embodiment 1 is that the third sub-pixel 1013 of Embodiment 2 is close to the pixel blocking unit of the first sub-pixel 1011 A first notch 31 is formed in the middle of the side wall. In this embodiment, the longitudinal cross-sectional shape of the first notch 31 is triangular, and the first notch 31 has an included angle α, and the included angle α is less than or equal to 20°. The depth of the first notch 31 thus formed is relatively deep, which can ensure the gap between the functional layer 4 on the surface of the anode unit 2 and the functional layer 4 on the surface of the pixel barrier unit 3 provided with the first notch 31 when the functional layer 4 is prepared. There is a gap, which prevents the lateral conduction between the third sub-pixel 1013 and the first sub-pixel 1011, thereby preventing the first sub-pixel 1011 from being lit...

Embodiment 3

[0065] Such as Figure 13 As shown, this embodiment includes most of the technical features of Embodiment 1. The difference between this embodiment and Embodiment 1 is that the third sub-pixel 1013 is close to the side of the pixel blocking unit 3 of the second sub-pixel 1012 The wall is provided with a second notch 34 . At this time, the length of the first gap 31 is smaller than the length of the third sub-pixel 1013 ; the length of the second gap 34 is smaller than the width of the third sub-pixel 1013 . Specifically, the length of the first gap 31 is shorter than the opening length L1 of the third sub-pixel 1013 ; the length of the second gap 34 is smaller than the opening width L2 of the third sub-pixel 1013 . In this way, the four corners of the third sub-pixel 1013 can be retained, ensuring that the cathode prepared later is continuous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com