Ventilation and heat dissipation device used in wind generating set

A wind turbine, ventilation and heat dissipation technology, which is applied in wind turbines, wind energy power generation, engines, etc., can solve the problems of insufficient passive heat dissipation, insufficient heat dissipation, and insufficient efficiency, and achieves easy installation, comprehensive heat dissipation, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

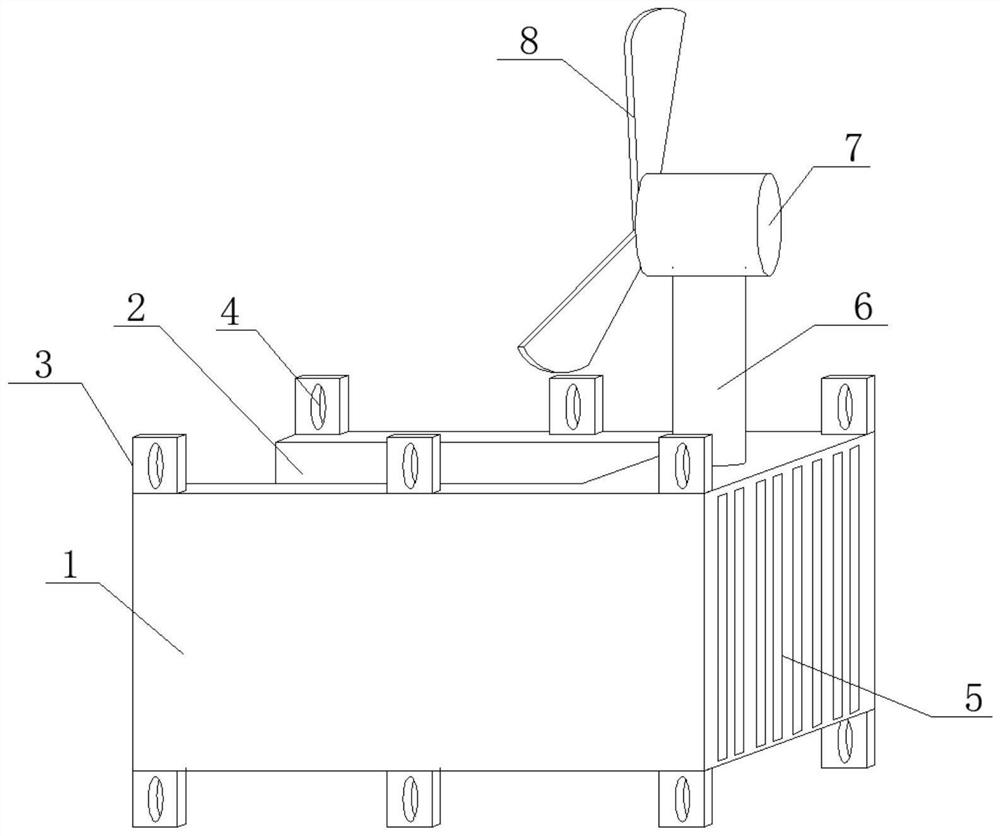

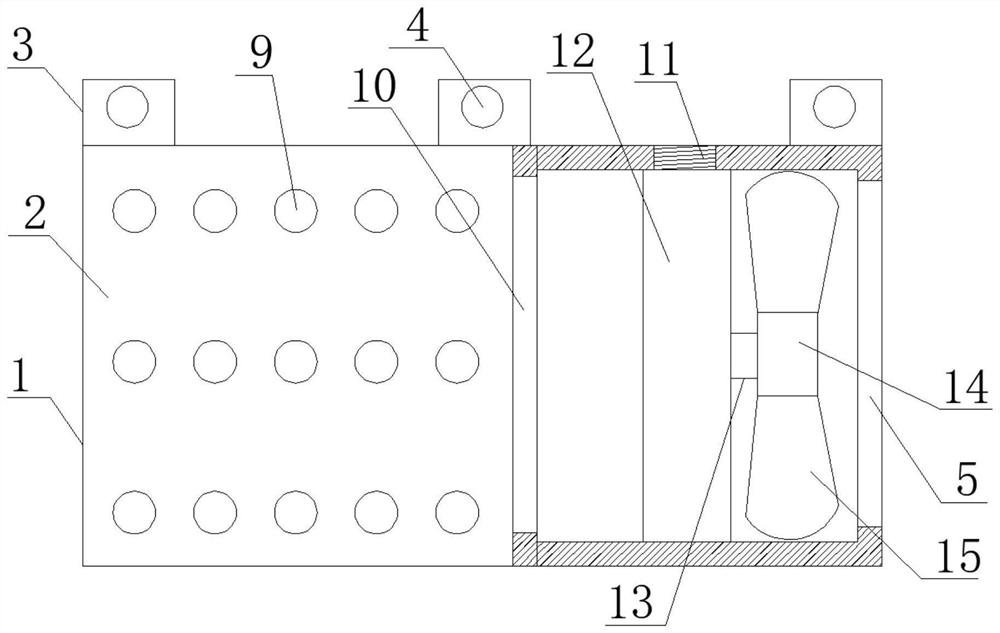

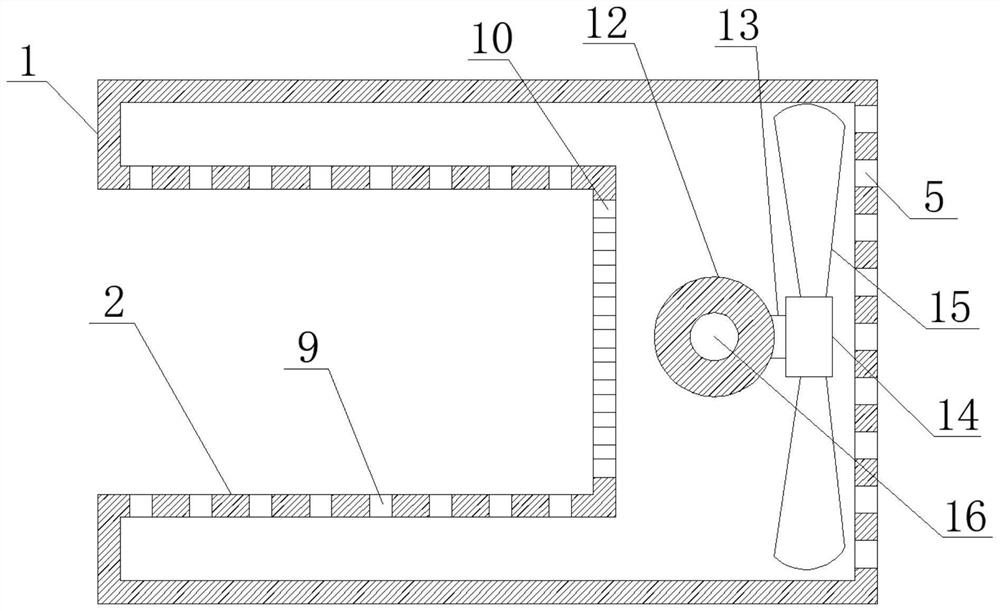

[0027] see Figure 1-2, in an embodiment of the present invention, a ventilation and heat dissipation device used in a wind power generating set, comprising a fixed outer box 1, one side of the fixed outer box 1 is horizontally provided with a buckle end groove 2, and the top surface of the fixed outer box 1 The side fixing block 3 is welded vertically to the bottom surface, and the side of the side fixing block 3 is provided with a connection through hole 4, and the fixed outer box 1 is provided with a ventilating grille 5 on the side far away from the buckle end groove 2, and the buckle end groove 2. Set horizontally at the center of one side of the fixed outer box 1, and extend through the three sides of the fixed outer box 1 to the outer position. The number of side fixing blocks 3 is multiple, and the number of side fixing blocks 3 It is fixedly arranged on the top surface and the bottom surface of the fixed outer box 1 close to the edge position, the inside of the air-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com