Concrete-filled steel tube beam column connecting joint capable of being replaced after earthquake

A technology for connecting concrete-filled steel tubes and beams and columns, which is applied in the fields of earthquake resistance, building types, and buildings. It can solve problems such as the difficulty of installing concrete-filled steel tube beams and columns, and the impossibility of rapid repair of concrete-filled steel tube structures, achieving stable support, convenient assembly, and integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

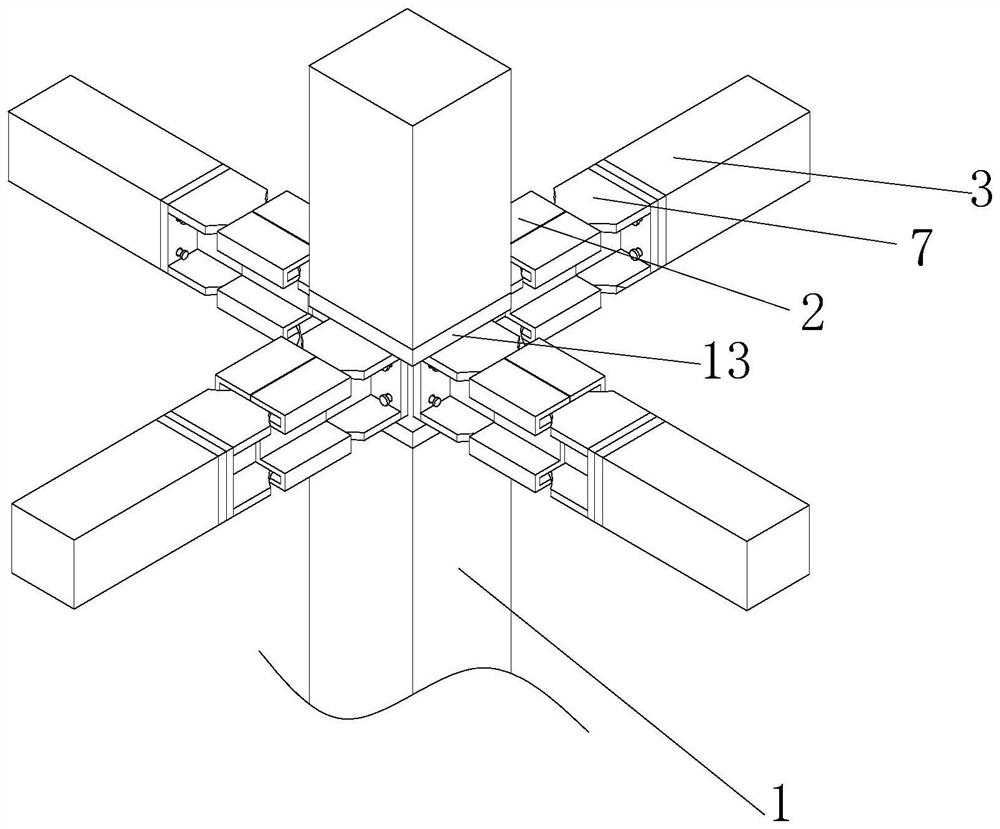

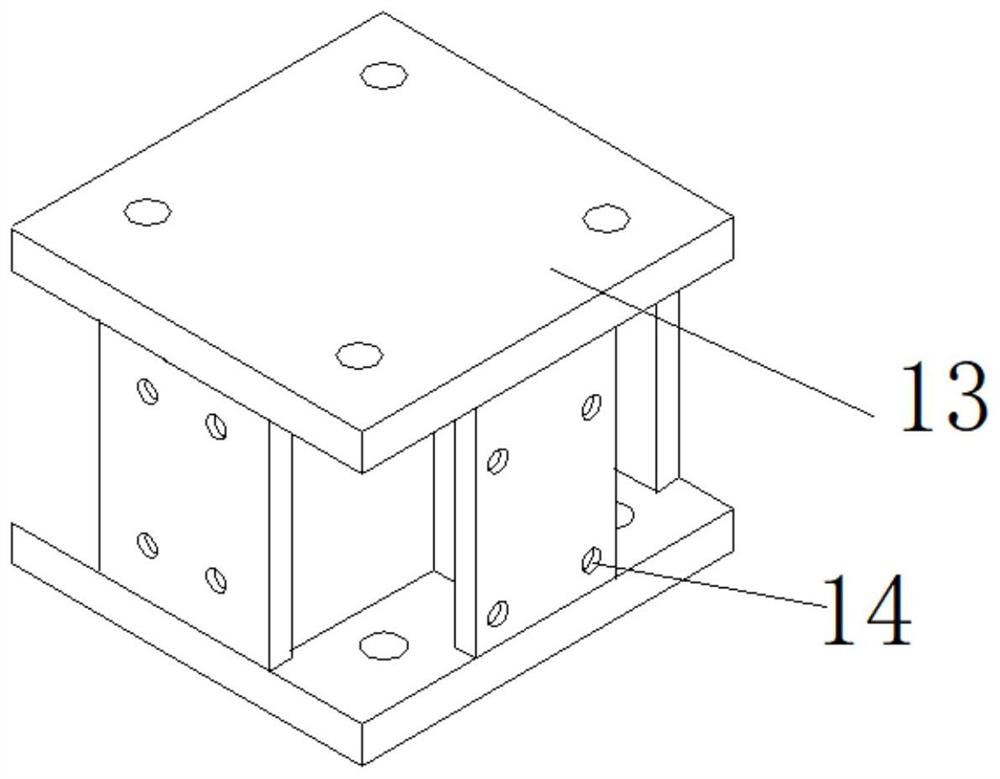

[0040] Such as Figure 1~4 A post-earthquake replaceable CFST beam-to-column joint is shown, including CFST columns 1. There are two CFST columns 1, namely the upper CFST column and the lower CFST column, and the upper CFST column and the lower CFST column. A prefabricated node frame 13 is arranged between the steel tube concrete columns. The prefabricated node frame 13 includes a cross-shaped steel member and six steel plates 5 welded on the upper and lower sides of the cross-shaped steel member and in the surrounding direction. The threaded holes 14 are provided at the four corners of the steel plate 5. A steel plate 5 is pre-embedded at the end of the steel tube concrete column and the lower steel tube concrete column opposite to the prefabricated node frame 13, and the four corners of the steel plate 5 are welded with threaded sleeves 15. The upper concrete-filled steel tube column and the lower steel tube concrete column are fixedly connected to the steel plates with thre...

Embodiment 2

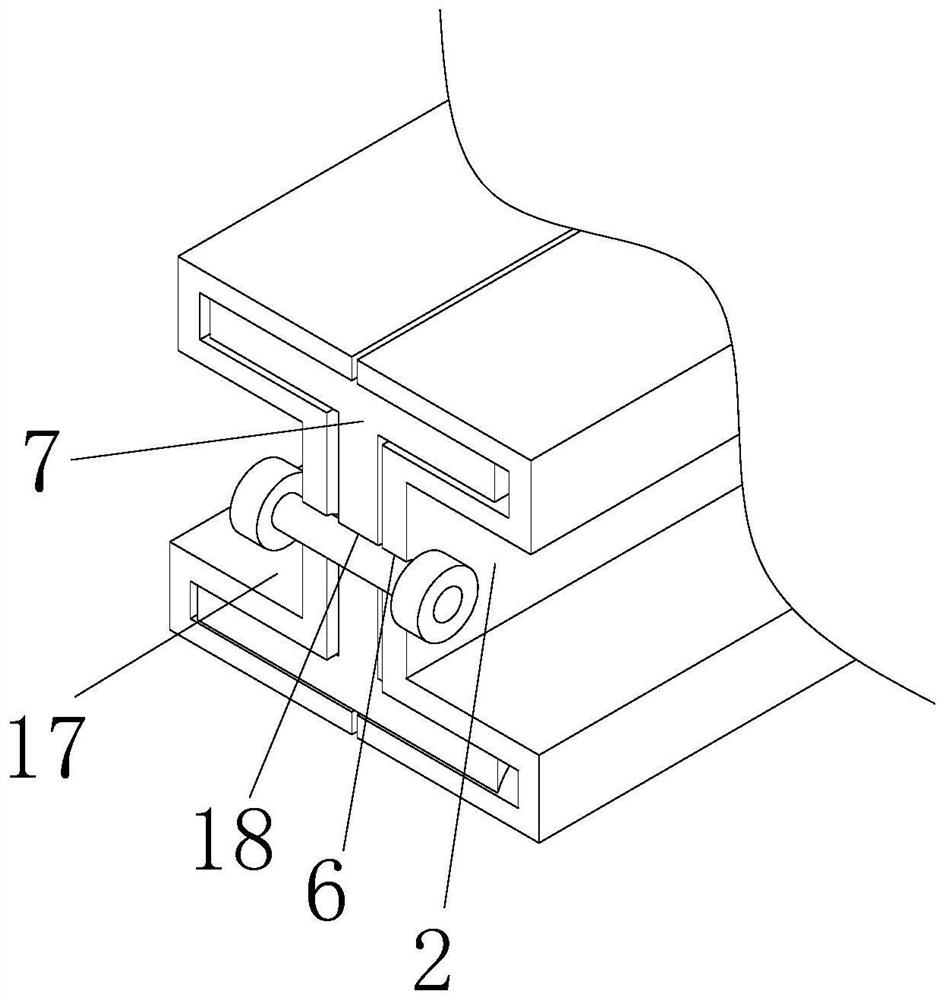

[0048] Such as figure 1 , 3 ~8 shows a post-earthquake replaceable steel pipe concrete beam-column connection node. The difference between Embodiment 2 and Embodiment 1 is that the bow-shaped connector 1 2 and the bow-shaped connector 2 17 are assembled on the bow-shaped connector 1 2 and the bow-shaped The steel beam 7 in the connector two 17 is fixed by fasteners, that is, the front side of the arc connector one 2 and the arc connector two 17 vertical plates are all provided with a draw-in groove 25, and the front and rear sides of the steel beam 7 vertical plates Both sides are fixedly connected with the support bar 11 that is slidingly connected to the inside of the card slot 25. The insides of the two support bars 11 are provided with the same structure. The inside of the support rod 11 extends to the outside of the support rod 11, and the inside of the support rod 11 is provided with a fixed support device.

[0049] The fixed supporting device comprises a power rod 10,...

Embodiment 3

[0054] Such as Figure 9 A post-earthquake replaceable concrete-filled steel tube beam-column connection node is shown. The difference between Embodiment 3 and Embodiment 1 is that the bow-shaped connector 1 2 and the bow-shaped connector 2 17 can also be assembled on the steel beam in a tooth-like splicing manner. 7, that is, the splicing parts of bow-shaped connector one 2 and bow-shaped connector two 17 are interspersed with thin steel bars 16 along the length direction, and the ends of thin steel bars 16 are welded to the joints of bow-shaped connector one 2 and bow-shaped connector two 17 to realize the bow-shaped connection The positions of the first piece 2 and the second bow-shaped connector 17 are fixed, and the first bow-shaped connector 2 and the second bow-shaped connector 17 are fixed on the steel beam 7 . In addition, the tooth shape can be square teeth, rectangular teeth or equilateral triangular teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com