Auxiliary bagging and receiving equipment for wheat bin opening

A wheat and equipment technology, which is applied to the field of auxiliary bag loading and receiving equipment at the mouth of the wheat warehouse, can solve the problems of wheat spilling on the outside of the snakeskin bag, low work efficiency, and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

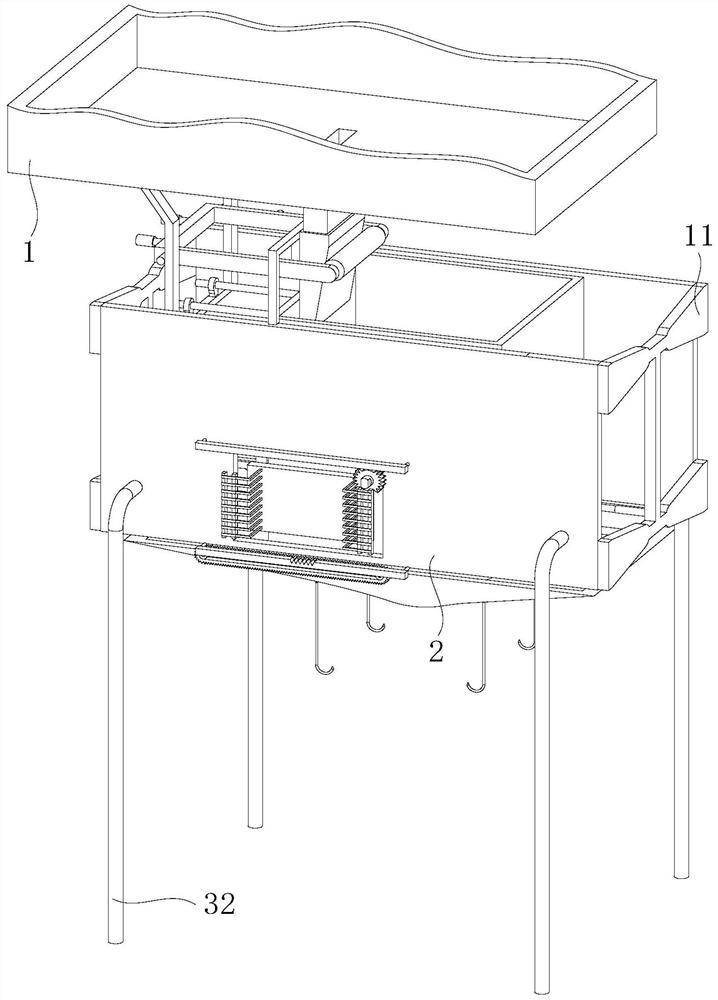

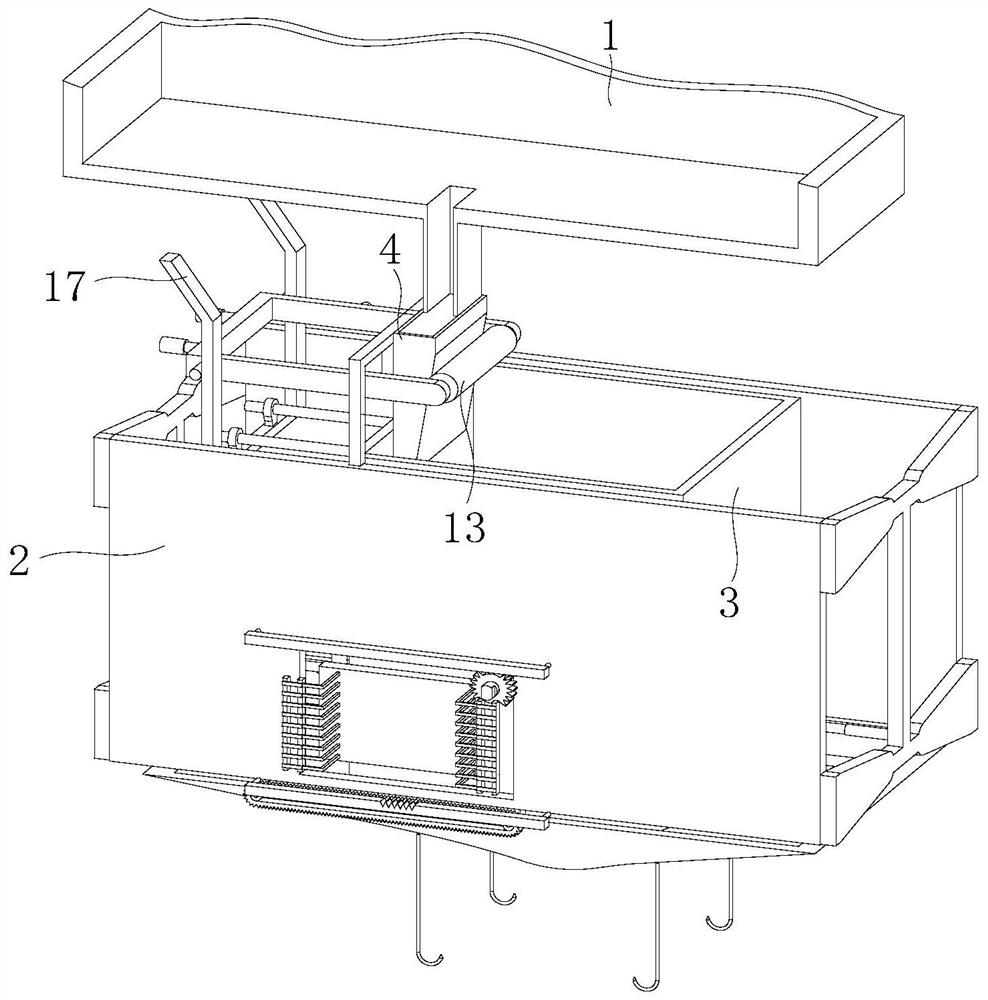

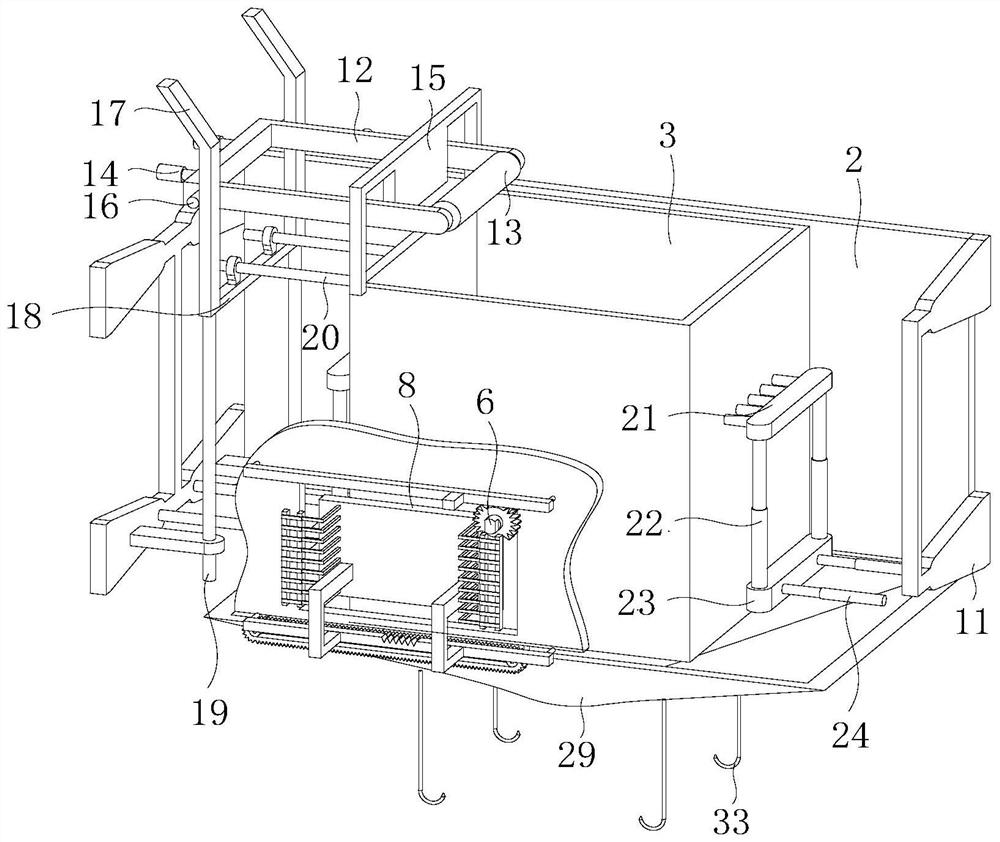

[0024] Such as Figure 1-7 As shown in the figure, a wheat bin opening auxiliary bagging material receiving equipment includes a bin body 1, two installation plates 2 are arranged under the bin body 1, and a material receiving device is arranged between the two installation plates 2 under the bin body 1. The inside of the box 3 and the receiving box 3 is provided with a hose 4, and the material of the hose 4 can be elastically deformed.

[0025] The upper end of the hose 4 is sleeved on the lower end of the bin body 1, and the inside of the material receiving box 3 is located below the hose 4 to be provided with a material receiving plate 5, and the front of the material receiving plate 5 is fixed through a support shaft 6, and the support shaft 6 The front and rear ends rotate respectively through the inner walls of the front and rear sides of the material box 3, and the fronts of the two mounting plates 2 are provided with a front-to-back limit slot 8, the shape of the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com