Manufacturing equipment and manufacturing process for environment-friendly activated carbon fiber cylinder

A technology of activated carbon fiber and manufacturing equipment, applied in the field of activated carbon fiber cylinder manufacturing equipment and manufacturing technology for environmental protection, can solve the problems of increasing labor intensity, slow speed, affecting the manufacturing process, etc., to facilitate disassembly and replacement, and improve manufacturing Speed, the effect of speeding up manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

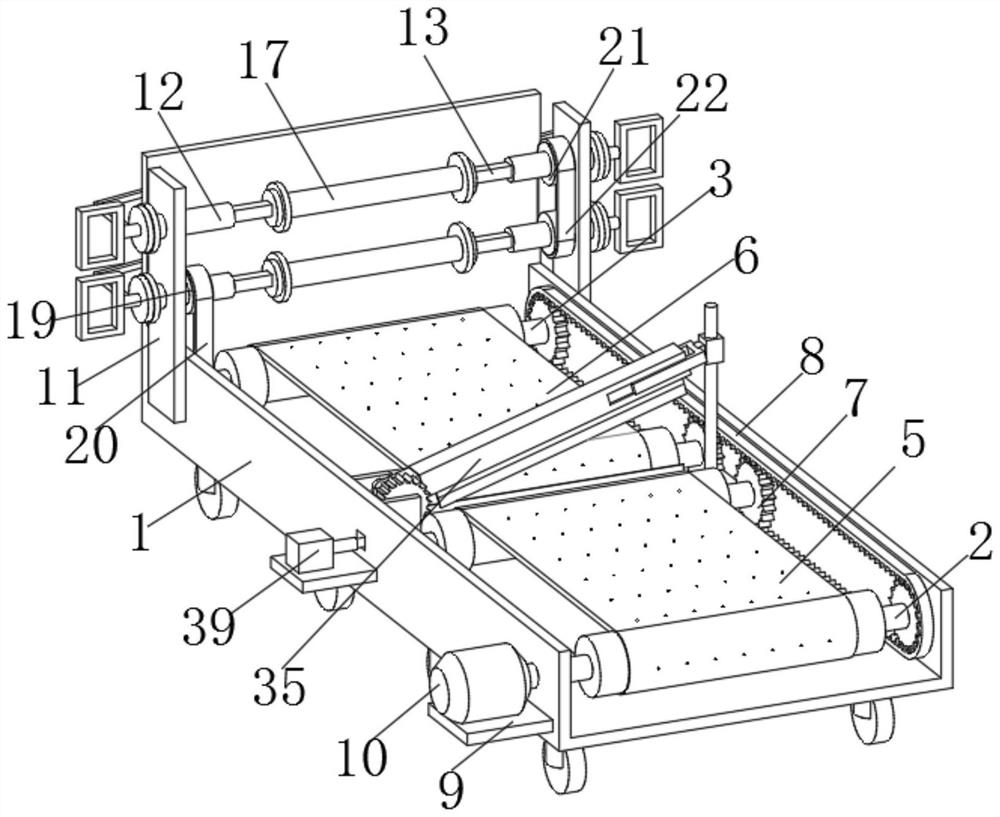

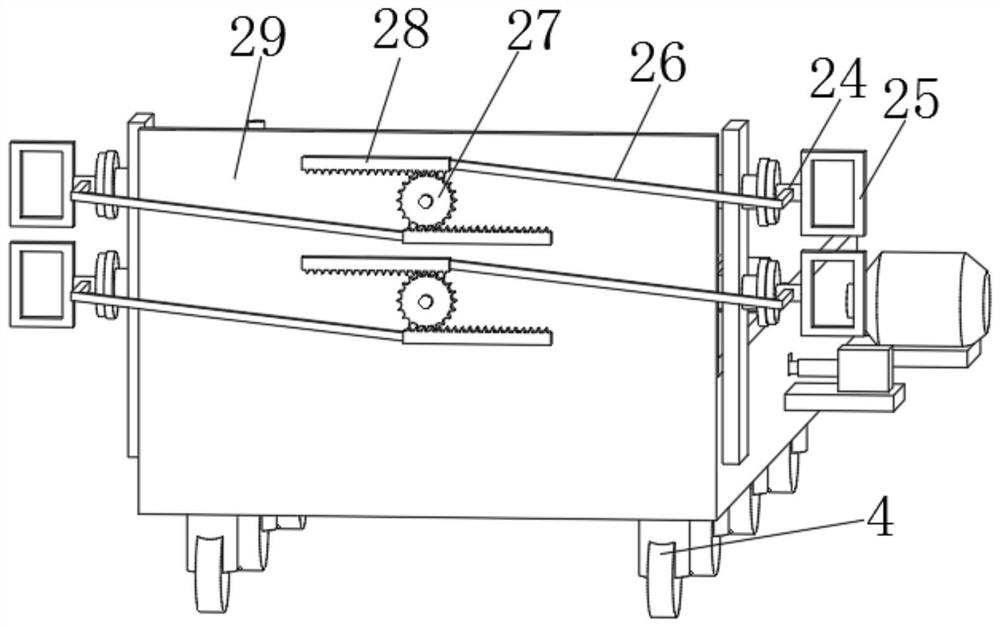

[0044] Example: Reference Figure 1-8 The shown one kind of activated carbon fiber cylinder manufacturing equipment for environmental protection includes a U-shaped frame 1, a drive unit, a fiber mat unwinding part, a fastening unit and a fiber felt cutting part, and the fastening unit has a linkage unit.

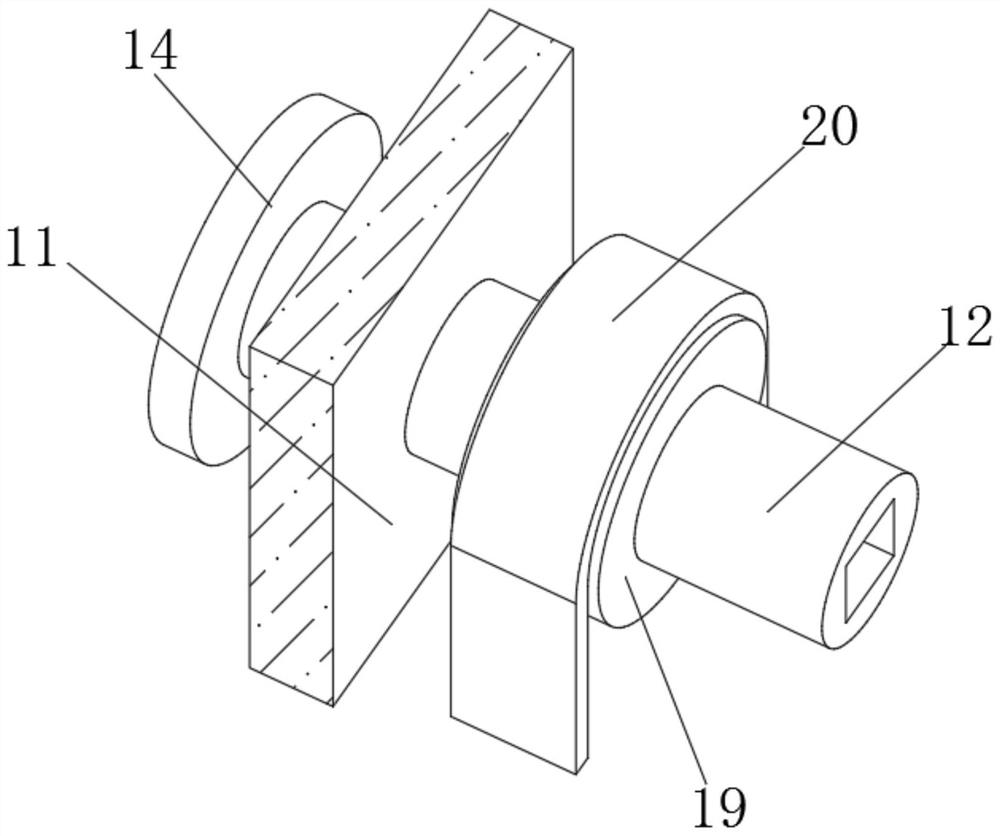

[0045] There are two first transmission shafts 2 and two second transmission shafts 3 connected to the inner rotation of the U-shaped frame 1, the two first transmission shafts 2 and the two second transmission shafts 3 are located on the same level, and the two first transmission shafts The same first conveyor belt 5 is tensioned on the transmission shaft 2, the same second conveyor belt 6 is tensioned on the two second transmission shafts 3, and two mounting plates 9 are fixedly connected to one side of the U-shaped frame 1. The plate 9 can be any flat plate in the prior art, such as a metal plate, and the mounting plate 9 can be fixedly connected to one side of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com