Panel-guide assembly in plain CRT

A planar cathode and ray tube technology, applied in the direction of cathode ray tube indicator, cathode ray tube/electron beam tube, cold cathode manufacturing, etc., can solve problems such as pollution, inability to remove foreign substances, blocking shadow mask perforation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

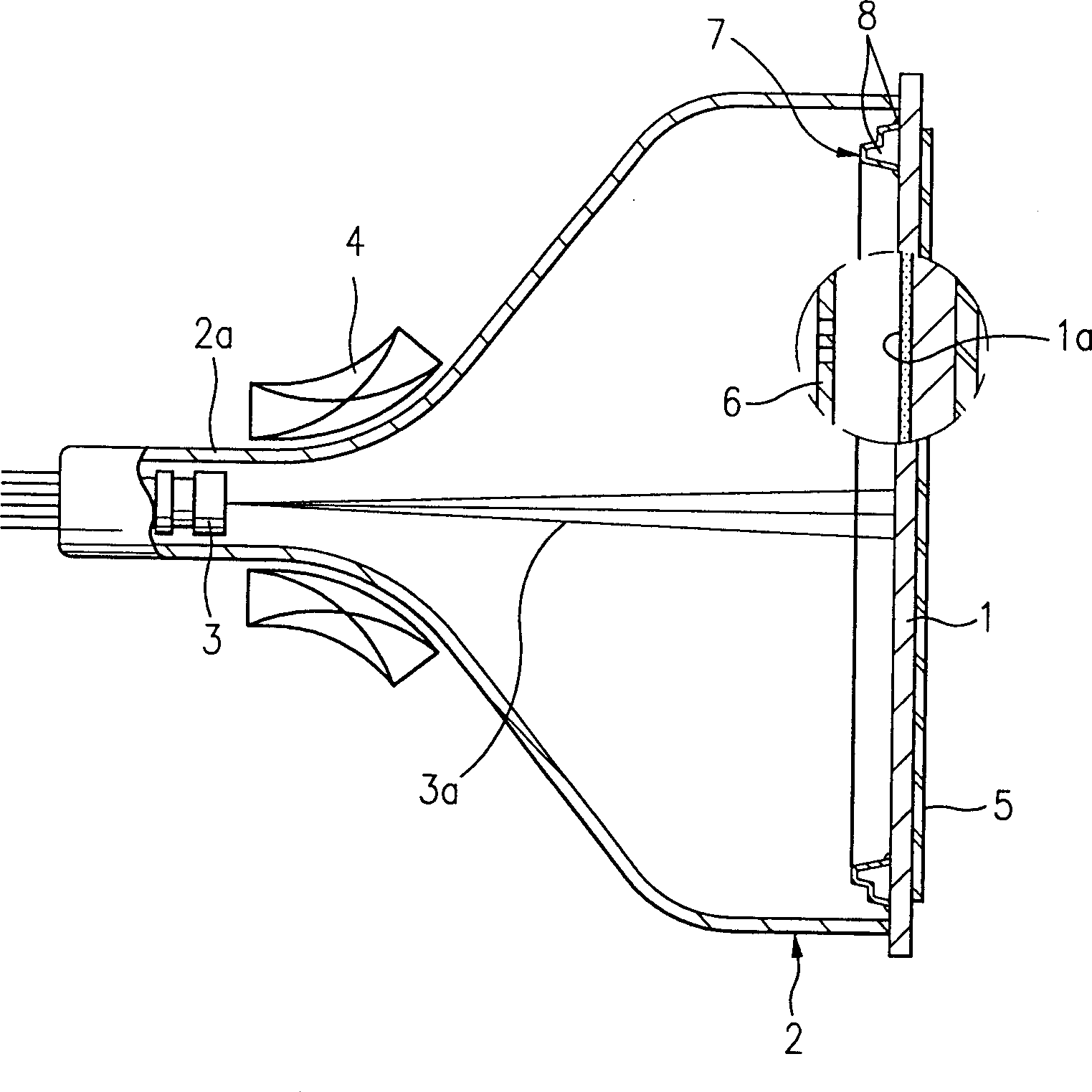

[0034] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

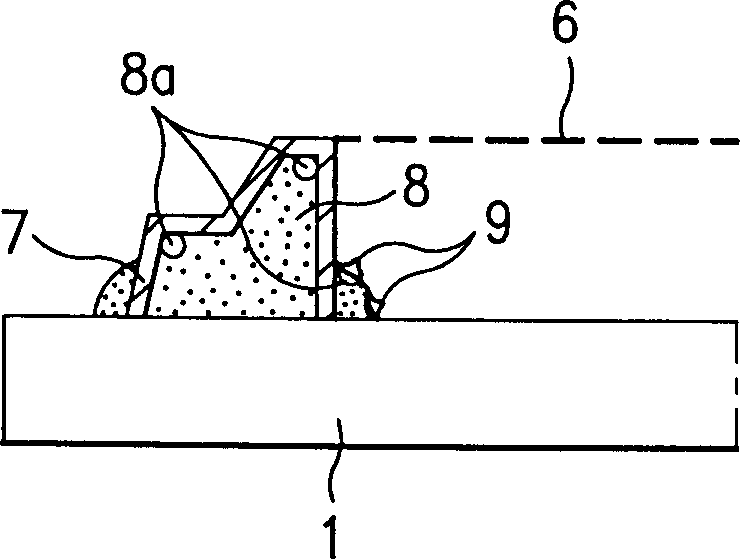

[0035] refer to Figure 3-5 , by coating the reaction catalyst aluminum AL or bismuth Bi on the guide rail assembly 1 to be bonded with the panel 1, and electrostatically bonding the panel 1 and the guide rail 7, the panel guide rail assembly of the present invention is processed. After coating the reaction catalyst, in the process of electrostatically bonding the panel 1 and the guide rail 7, the panel and the guide rail are aligned, and the required pressure (1-20Kgf / cm 2 ) is applied to them, the heating is roughly 300-520°C, and they are bonded with a suitable voltage selected in the range of DC200-4000V, and cooled to complete the bonding process.

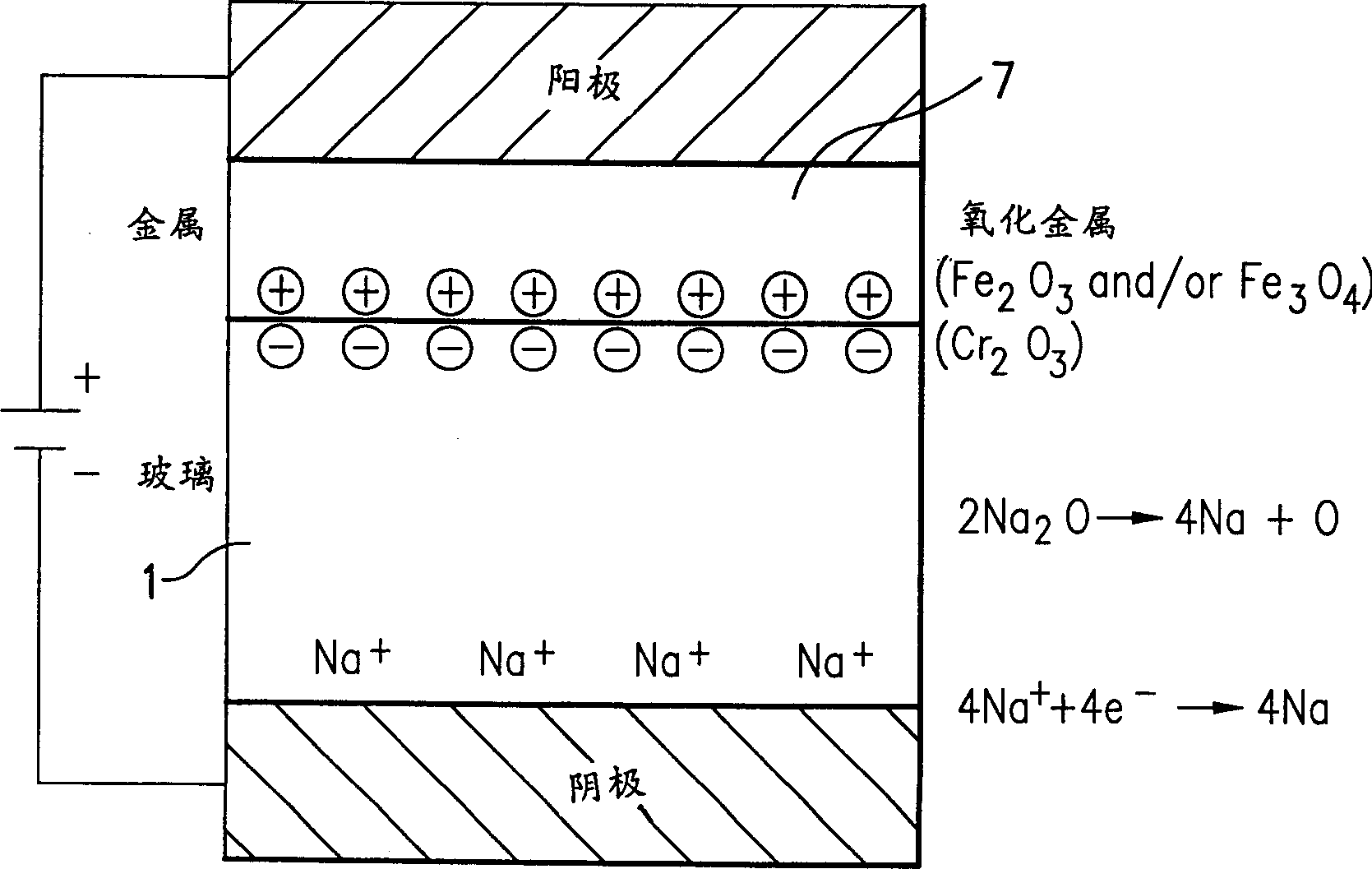

[0036] At the same time, if image 3 As shown, the basic principle of electrostatic bonding employed in the present invention is to bond glass (panel) to metal (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com