Rectangular coordinate type submerged-arc welding robot

A rectangular coordinate, submerged arc welding technology, used in welding equipment, welding accessories, arc welding equipment and other directions, can solve problems such as high cost, poor weld consistency, and many types, avoiding waste, triggering fast, and fully functional. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

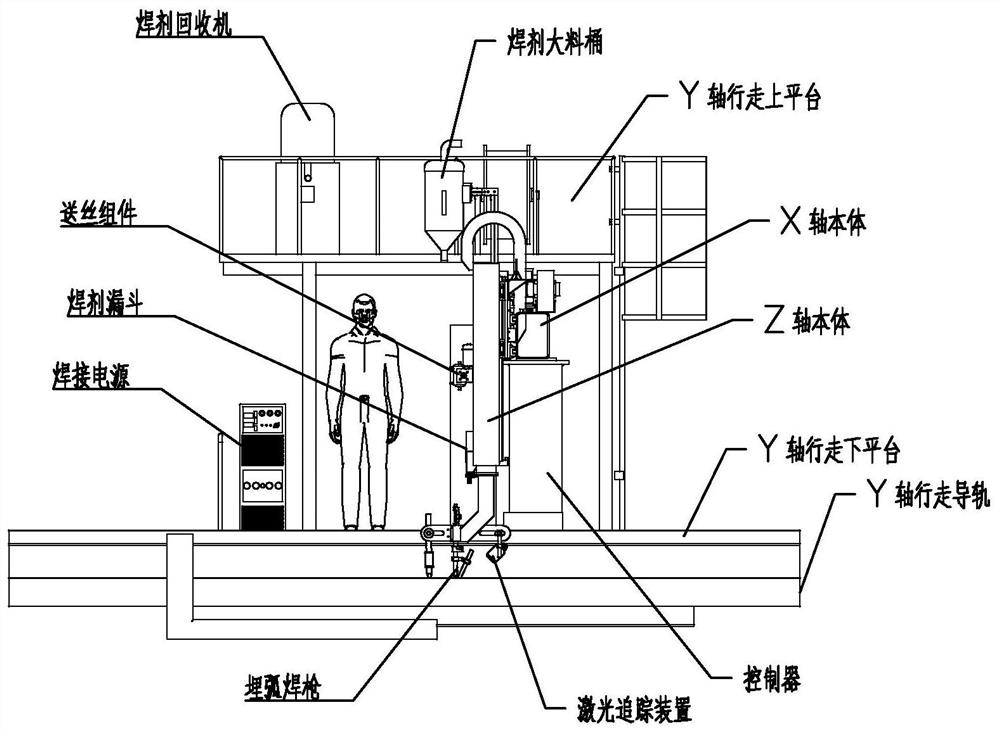

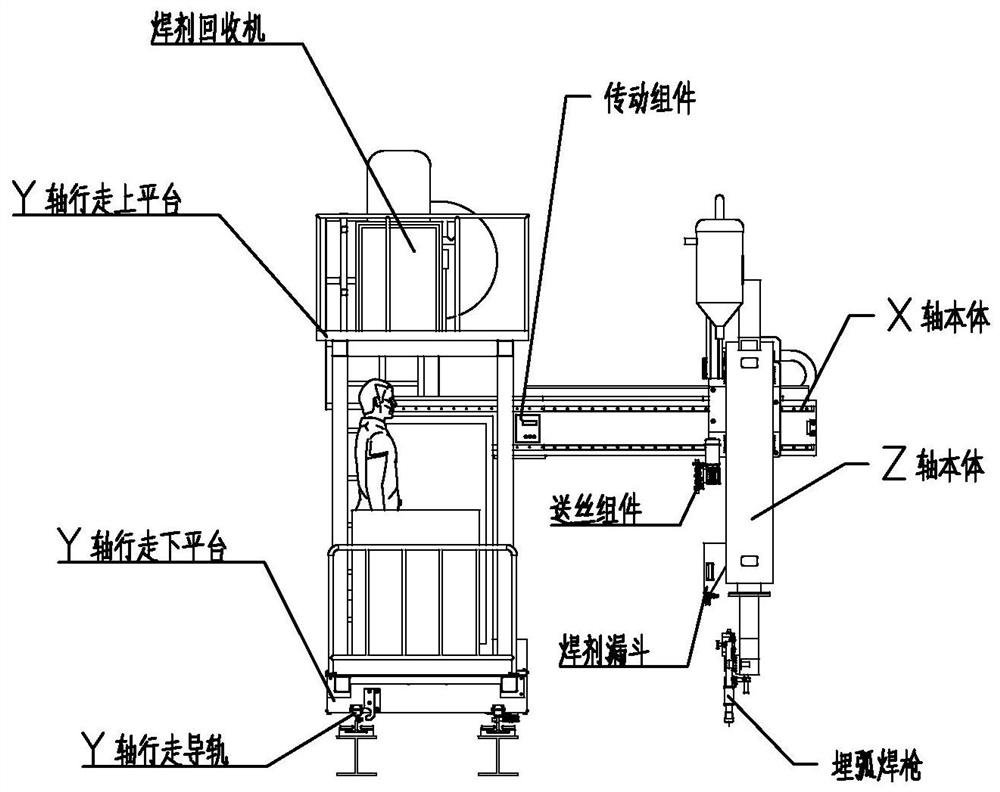

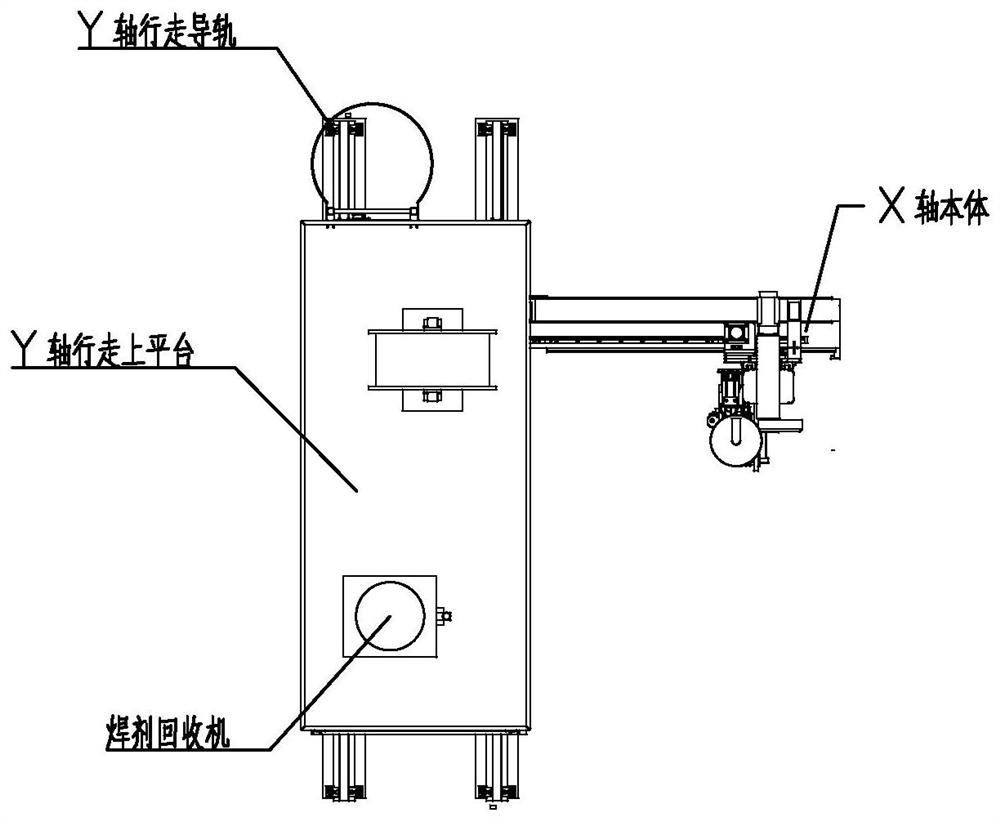

[0037] Such as Figure 1-12 As shown in the Cartesian coordinate submerged arc welding robot, including:

[0038] A controller, the controller is used to transmit control instructions, receive detection signal data and set welding parameters, so as to realize automatic welding;

[0039] Cartesian coordinate motion device, the rectangular coordinate motion device is used to adjust the welding position, and the Cartesian coordinate motion device includes a Y-axis walking lower platform, a Y-axis walking upper platform, an X-axis body and a Z-axis body that are arranged in cooperation. The Y-axis walking guide rail is connected to the Y-axis walking lower platform through the transmission assembly. The Y-axis walking guide rail is used to drive the Y-axis w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com