Method for preparing fluoride-free continuous casting covering slag from used lithium battery saggar

The technology of continuous casting mold powder and saggar is applied in the field of continuous casting mold powder, which can solve the problem of insignificant economic benefit of recycling, achieve obvious social and economic benefits, and realize the effect of recycling waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

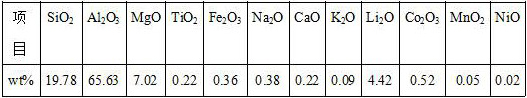

Embodiment 1

[0029] A new type of fluorine-free continuous casting mold powder, the preparation raw materials of its pre-melting material are: saggar crushed powder after use, 40%, (Al 2 O 3 +SiO 2 +MgO)>91.5%, 2 >99.2%, 2 CO3>99.1%, 2 CO 3 >99%, 3 (R is one of Mg, Ca, Ba): 7%, RCO 3 >98%, 2 >98%, <3μm. After the above powders are mixed uniformly, they are pre-melted in an electric furnace to form slag, and then a glassy pre-melt is obtained by quenching, and crushed to a particle size of less than 50 μm.

[0030] The above-mentioned pre-melting powder, anhydrous borax, carbonaceous raw materials, water-fusible nitrogen-based resin, and water are proportioned according to the following mass fractions: pre-melting powder, 90%, 2 B 4 O 7 >99.2%, 0.1 mm.

[0031] The viscosity at 1300°C of the fluorine-free continuous casting mold flux prepared by the above method is 0.32 Pa·s, and the melting point is 1088°C.

Embodiment 2

[0033] A new type of fluorine-free continuous casting mold powder, the preparation raw materials of its pre-melting material are: saggar crushed powder after use, 70%, (Al 2 O 3 +SiO 2 +MgO)>93.2%, 2 >99.3%, 2 CO3>99.2%, 2 CO 3 >99%, 3 (R is one of Mg, Ca, Ba): 3%, RCO 3 >98%, 2 >98%, <3μm. After the above powders are mixed uniformly, they are pre-melted into slag in an electric furnace, and glassy pre-melt is obtained by quenching and crushed to a particle size of less than 50 μm.

[0034] The above-mentioned pre-melting powder, anhydrous borax, carbonaceous raw materials, water-fusible nitrogen-based resin, and water are proportioned according to the following mass fractions: pre-melting powder, 80%, 2 B 4 O 7>99.1%, 0.1mm.

[0035] The fluorine-free continuous casting mold flux prepared by the above method has a viscosity of 0.11 Pa·s at 1300 °C and a melting point of 1027 °C.

Embodiment 3

[0037] A new type of fluorine-free continuous casting mold flux, the raw material for the preparation of the premelt is: crushed powder from the used sagger, 65%, (Al 2 o 3 +SiO2 2 +MgO)>90.6%,2 >99.3%, 2 CO3>99%, 2 CO 3 >99.2%, 3 (R is one of Mg, Ca, Ba): 5%, RCO 3 >98.2%, 2 >98%, <5μm. After the above powders are mixed, they are pre-melted into slag in an electric furnace, and the glassy pre-melt is obtained through rapid cooling, and crushed to a particle size of <50 μm.

[0038] The above-mentioned premelting powder, anhydrous borax, carbonaceous raw material, water-soluble nitrogen-based resin, and water are proportioned according to the following mass fractions: premelting powder, 81%, 2 B 4 o 7 >99.2%, 0.1 mm.

[0039] The fluorine-free continuous casting mold flux prepared by the above method has a viscosity of 0.23 Pa·s at 1300 °C and a melting point of 1052 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com