Straightening machine with downward pressing starting point detection function

A straightening machine and functional technology, applied in the direction of forming tools, manufacturing tools, feeding devices, etc., can solve the problems of workpiece damage, inability to remove rust, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

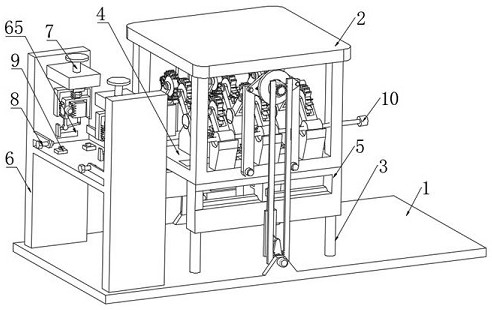

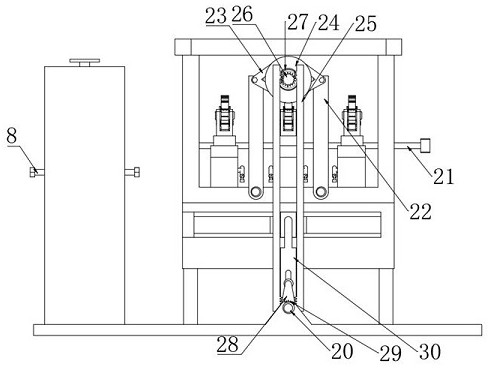

[0035] refer to Figure 1-10 , a straightening machine with the function of detecting the starting point of pressing down, comprising a base 1 .

[0036] The upper side of the base 1 is provided with a plurality of mounting seats 6, and a placement plate is arranged between the two adjacent mounting seats 6. Both are provided with a receiving seat and a straightener 65, and the receiving seat is provided with a sliding column 7 that can be slid up and down with the receiving seat, and the top of the sliding column 7 is provided with a limit cap, and the bottom of the receiving seat is provided with a limit cap on the sliding column 7. The bit block and the connecting block 19, and the sliding column 7 are threadedly connected with the connecting block 19 and the receiving seat, the both sides of the connecting block 19 are provided with a transmission seat 17, and the inner side of the transmission seat 17 on the left is provided with a No. 1 transmission rack , the lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com