Apparatus and method for performing grid partition automatic random sampling on powder materials

A technology of random sampling and random selection, applied in sampling devices, measuring devices, instruments, etc., can solve the problems of errors, low sampling efficiency, random effects of sampling, etc., to ensure consistency, reduce labor input, and randomness. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

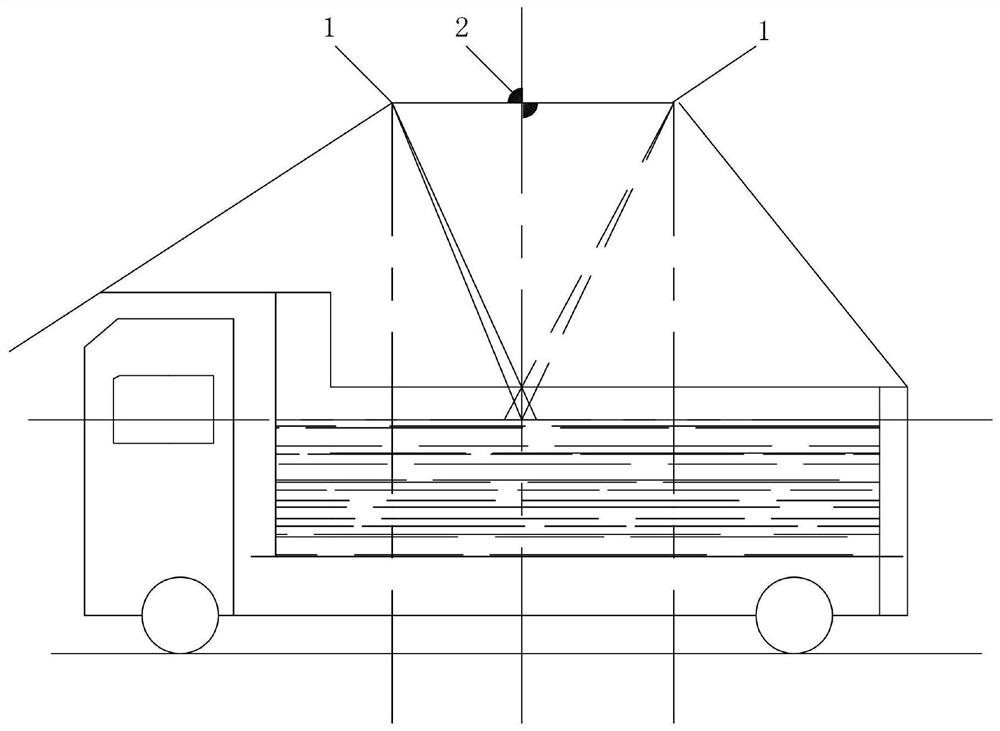

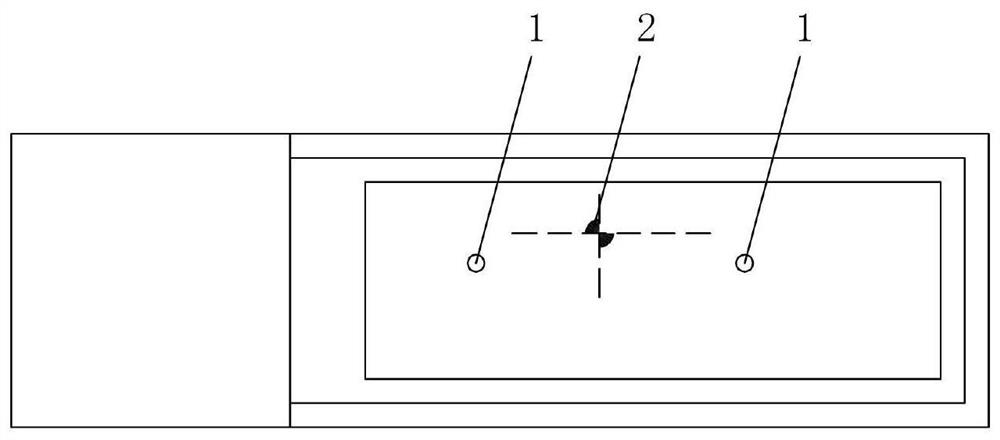

[0042] The equipment for automatic random sampling of powder in grid partitions in this embodiment includes:

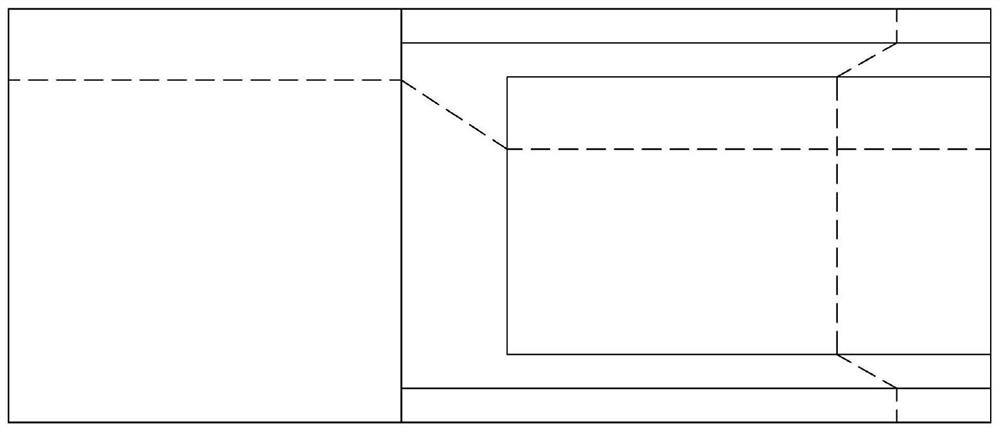

[0043] Partition module: used to divide the powder to be sampled into i×j areas, i≥1, j≥1; and randomly select n areas equal to the number n to be sampled, and divide the n areas into multiple A small grid, randomly select a small grid in each selected area, and send the position information of the small grid to the control module;

[0044] Control module: used to receive the small grid position information sent by the partition module, and control the sampling mechanism to take samples according to the small grid position information;

[0045] Sampling mechanism: installed above the powder to be sampled, it is used to be driven by the control module to insert into the powder in the vertical direction and obtain powder samples.

[0046] The equipment in this embodiment completely relies on automatic partitioning and random selection to select the sampling location. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com