Chemical etching process for preparing AG (anti-glare) glass

A chemical etching and anti-glare technology, applied in the field of glass surface treatment, can solve the problems of high technical requirements for filming, affecting glass quality, material waste, etc., to avoid material waste and environmental pollution, save manpower and material resources, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

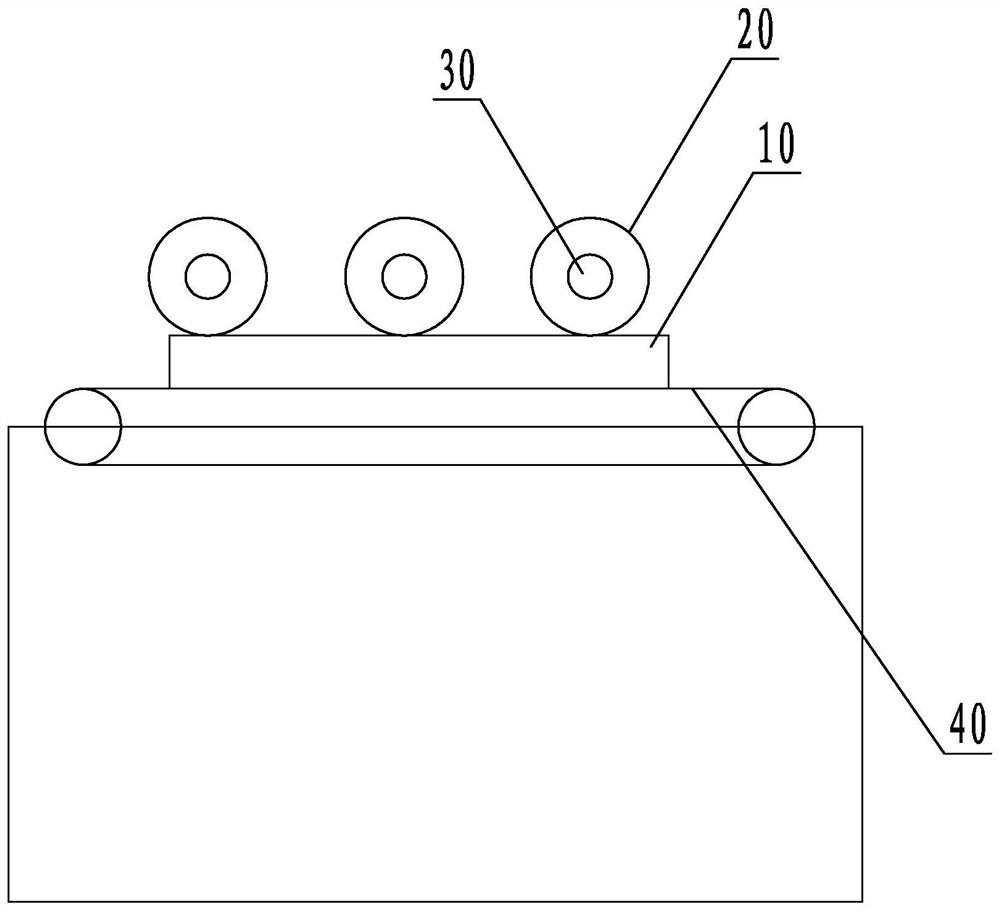

Image

Examples

Embodiment Construction

[0024] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will now be further described in detail in conjunction with examples.

[0025] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions throughout.

[0026] The orientations shown in the drawings should not be construed as limiting the specific protection scope of the present invention, but are only for reference and understanding of preferred embodiments, and the product components shown in the drawings can be changed in position or increased in number or simplified in structure.

[0027] The "connection" described in the specification and the "connection" relationship between the parts shown in the drawings can be understood as fixed connection or detachable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com