Winding wire for large-diameter high-pressure flexible composite pipe and using method thereof

A flexible composite pipe and large-diameter technology, which is used in the field of pipeline transportation and fiber-reinforced thermoplastic pipes, can solve problems such as difficulty in processing large-diameter, high-pressure pipes, uneven stress on multi-layer fibers, and low pressure-bearing capacity of flexible composite pipes. , to achieve the effect of facilitating processing and solving the large stress on the inner layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

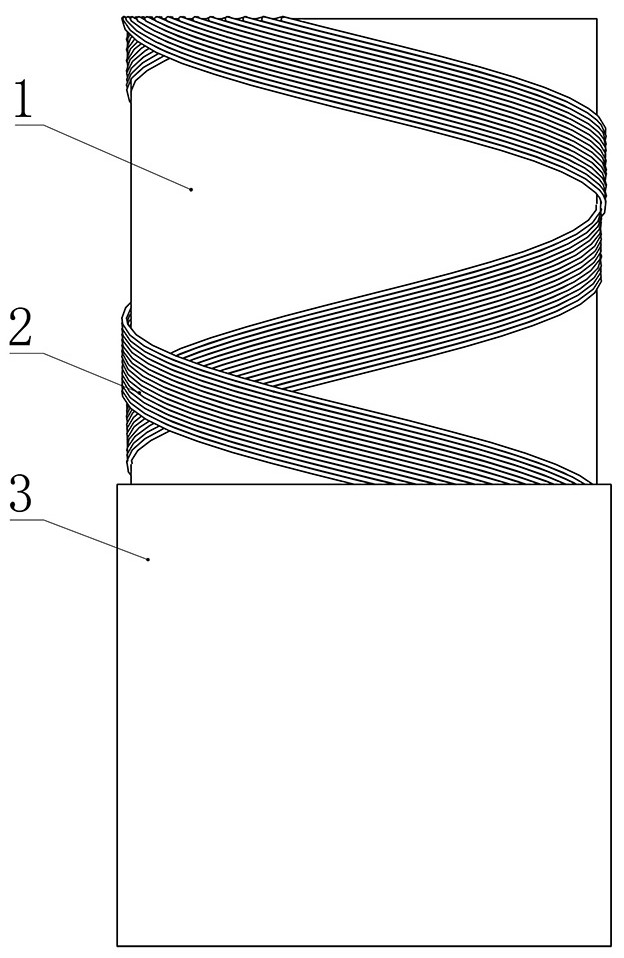

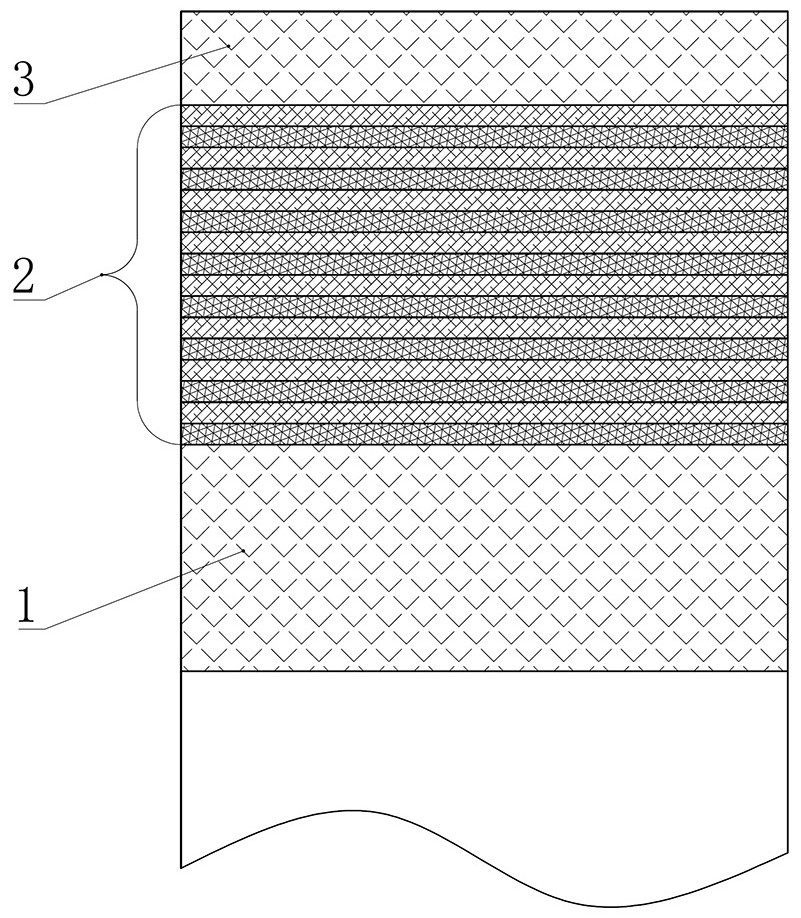

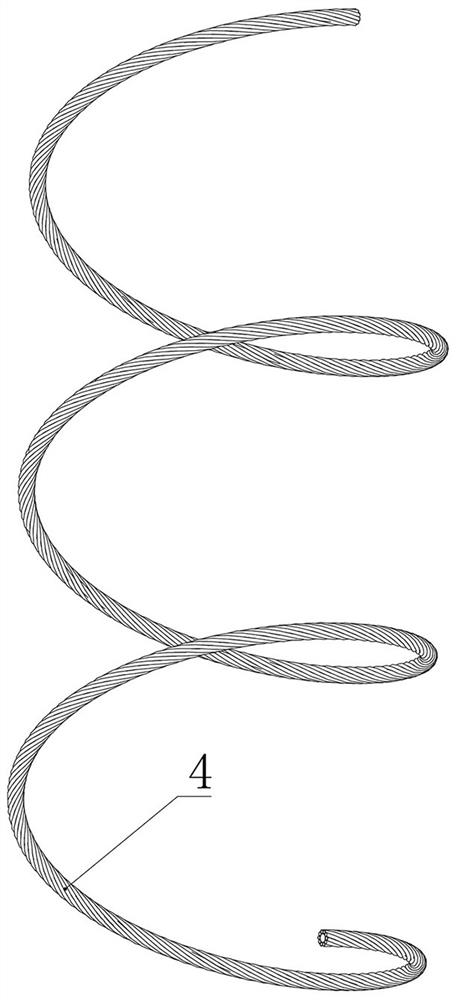

[0048] Embodiment 1: The inner lining layer 1 has an inner diameter of 600 mm, the inner lining layer 1 adopts a polyethylene pipe with a wall thickness of 22 mm, the inner core 41 of the winding 4 adopts a solid rubber wire with a diameter of 3 mm, and the fiber bundle 43 is aramid fiber, and the inner core is made of aramid fiber. The surface of 41 is provided with aramid fibers arranged along the axial direction of the inner core 41, the volume ratio of the fiber bundle 43 to the inner core 41 is 0.7:1, the angle between the winding direction of the winding 4 and the axis of the pipeline is 55°, and the twist of the fiber bundle 43 is zero; The winding 4 is spirally wound on the inner lining layer 1 to form an 8-layer reinforcement layer 2; between the adjacent layers of the reinforcement layer 2, the winding direction of the winding 4 is opposite; the fibers between the adjacent layers of the reinforcement layer 2 The bundle 43 is wound in the opposite direction to the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com