Separation membrane and preparation method thereof, membrane separation equipment and sewage treatment method

A technology for separating membranes and ions, applied in the field of membrane separation, can solve the problems of low water flux, reduced selectivity, hindering the application and promotion of natural polymer separation membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

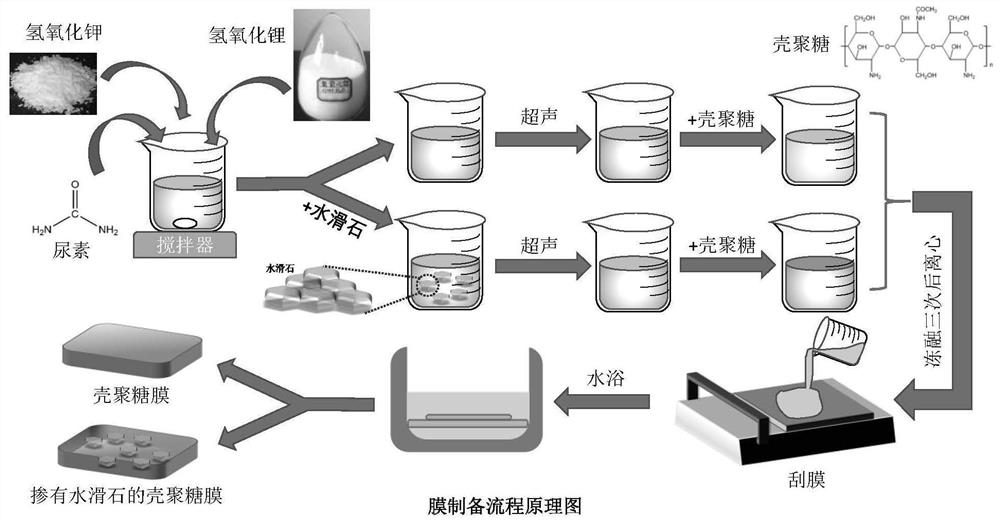

Method used

Image

Examples

preparation example Construction

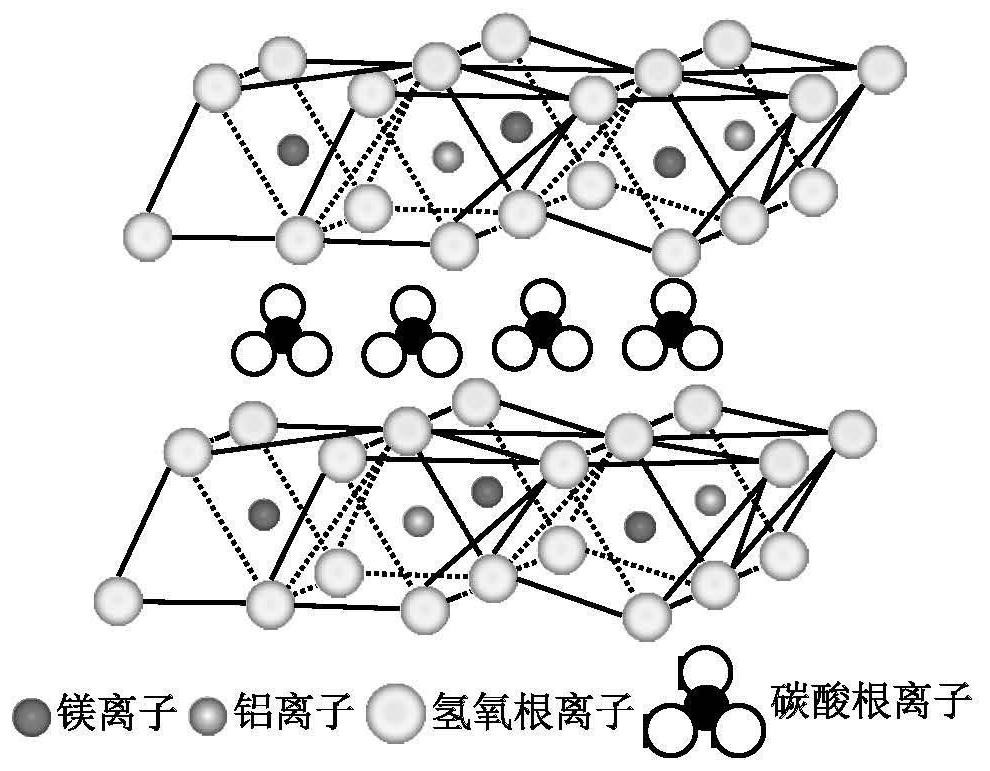

[0063] The raw materials for the preparation of layered double metal hydroxide nanoparticles can be commonly used raw materials in this field, such as using Mg, Cu, Co, Zn, Ni, etc. as divalent metal ions, and using Al, Ti, Fe, Sc, Cr, etc. as Trivalent metal ions, with a variety of inorganic, organic or complex anions as intercalation anions (including carbonate, nitrate, sulfate, phosphate, chloride, stearate, dodecylsulfonate, fatty acid, etc. ). Different elements can be selected as raw materials for forming hydrotalcite nanoparticles.

[0064] Specifically, the layered double metal hydroxide nanoparticles are selected from at least one of hydrotalcite nanoparticles and hydrotalcite-like nanoparticles. In one embodiment, the layered double hydroxide nanoparticles are hydrotalcite nanoparticles.

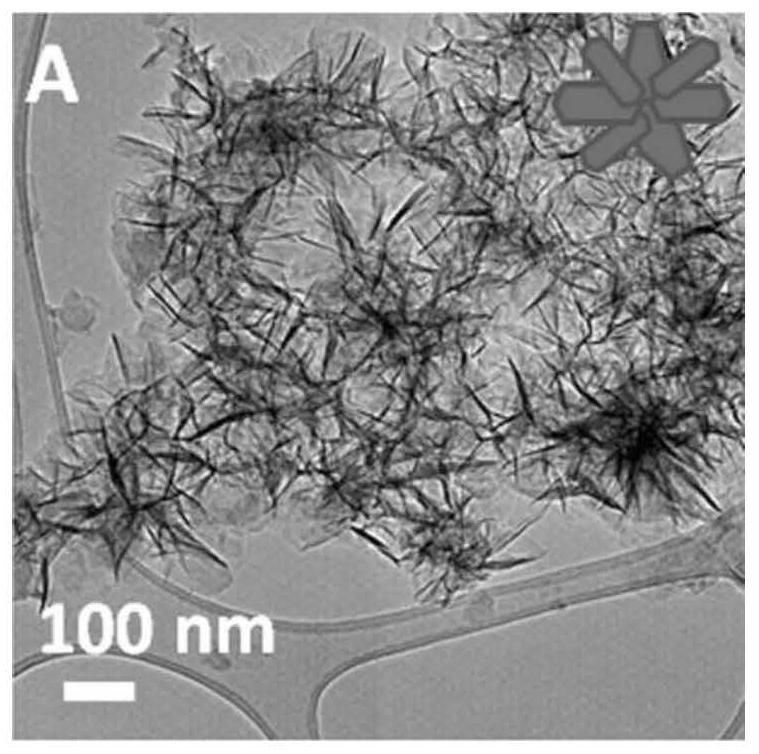

[0065] In one embodiment, the elements of the hydrotalcite nanoparticles include hydroxides of divalent Mg and trivalent Al, with carbonate as an anion. The interlayer spacing ...

Embodiment 1

[0114] This embodiment provides a separation membrane with nanoparticles doped with natural polymers. The raw materials for the preparation of the separation membrane include: hydrotalcite nanoparticles and chitosan. The particle diameter of the hydrotalcite nanoparticle is 200nm, the hydrotalcite nanoparticle has a multilayer structure, and the mass of the hydrotalcite nanoparticle is 2% of the chitosan mass. The hydrotalcite nanoparticles in this example use magnesium ions as divalent metal ions, aluminum ions as trivalent metal ions, and carbonate ions as anions, which can be prepared by the preparation method in Example 10. The schematic diagram of the structure of the hydrotalcite nanoparticles of the present embodiment is as figure 2 shown.

[0115] This embodiment also provides a method for preparing a separation membrane, the specific steps are as follows:

[0116] Urea, potassium hydroxide and lithium hydroxide monohydrate (LiOH·H 2 O) Dissolve in ultrapure water ...

Embodiment 2

[0118] This embodiment provides a nanoparticle-doped natural polymer separation membrane, and the preparation raw materials of the separation membrane include: hydrotalcite nanoparticles and chitosan. The particle diameter of the hydrotalcite nanoparticle is 200nm, the hydrotalcite nanoparticle has a multilayer structure, and the mass of the hydrotalcite nanoparticle is 0.5% of the chitosan mass. The hydrotalcite nanoparticles in this example use magnesium ions as divalent metal ions, aluminum ions as trivalent metal ions, and carbonate ions as anions, which can be prepared by the preparation method in Example 10.

[0119] This embodiment also provides a method for preparing a separation membrane, the specific steps are as follows:

[0120] Urea, potassium hydroxide and lithium hydroxide monohydrate (LiOH·H 2 O) Dissolve in ultrapure water and stir on a magnetic stirrer until completely dissolved to obtain a solution. In the solution, the mass percentages of urea, potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com