Full-automatic production equipment for RO membrane filter element and processing technology of RO membrane filter element

A production equipment, fully automatic technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the process of stacking, rolling and wrapping film can not be carried out continuously, low degree of automation, time-consuming and labor-intensive, etc. problems, to achieve the effect of reducing the number of cuts, high degree of automation, and less error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

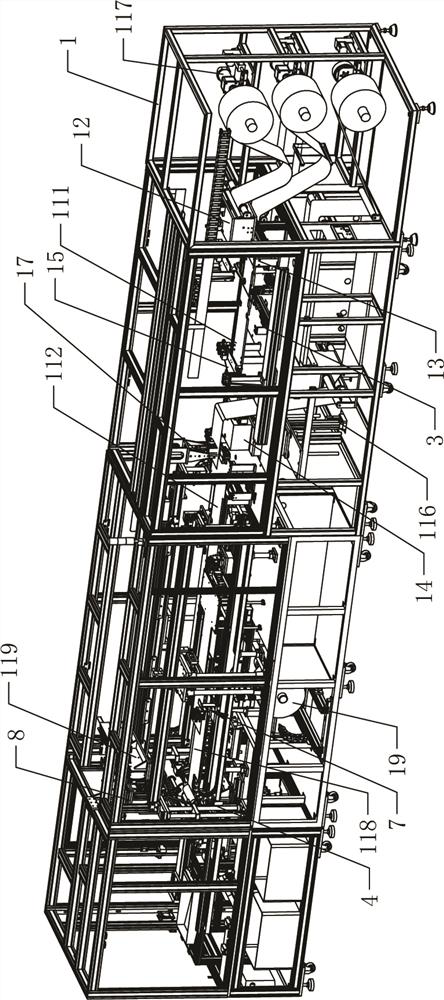

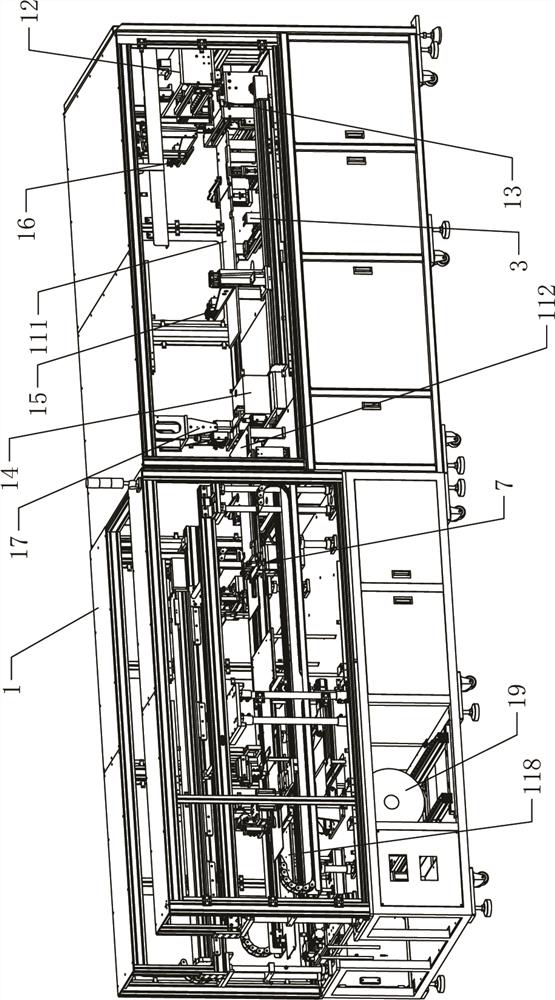

[0049] A kind of fully automatic production equipment and processing technology of RO membrane filter element, such as Figure 1-4 As shown, it includes a frame 1, a first placement platform 111 and a second placement platform 112 located on the frame 1, a conveying channel is formed between the first placement platform 111 and the second placement platform 112, and the frame 1 is provided with A material mechanism, a lamination mechanism, a bundle mechanism and an error correction and diversion mechanism 9 for blanking.

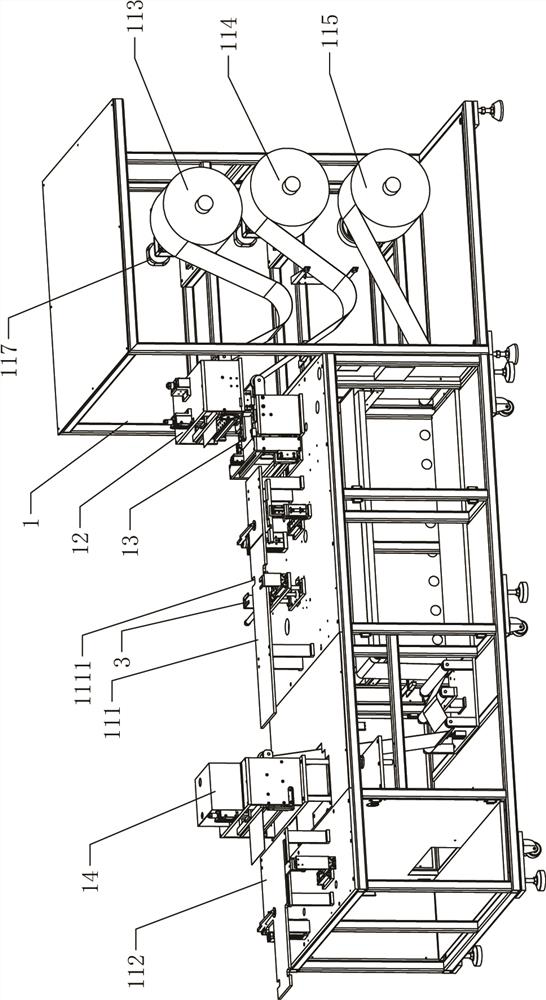

[0050] Such as image 3 As shown, the initial end of the frame 1 is provided with three material reels, and the three material reels are arranged in sequence along the vertical direction. The upper material reel is used to place the mesh material reel 113, and the middle material reel is used to place the diaphragm. The material roll 114, the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com