Preparation method of bletilla striata extract with repairing and whitening effects and bletilla striata extract

The technology of extract and Bletilla striata, which is applied in the field of Bletilla striata extract, can solve the problems of hidden safety hazards, high production cost, inability to apply Bletilla striata extract, etc., and achieves the effect of skin safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

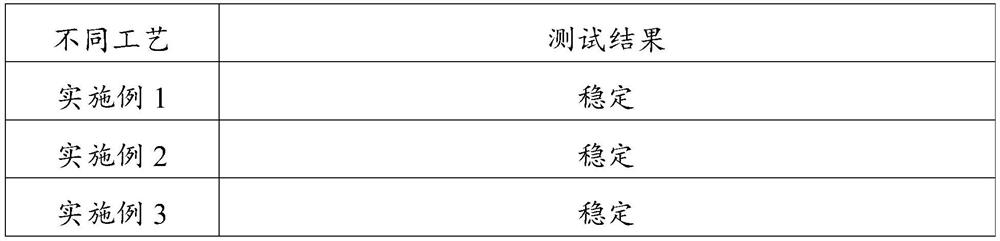

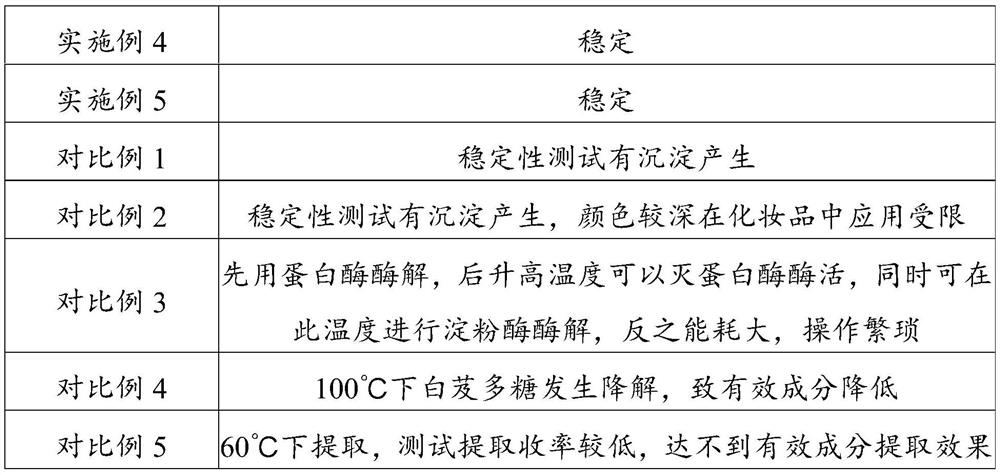

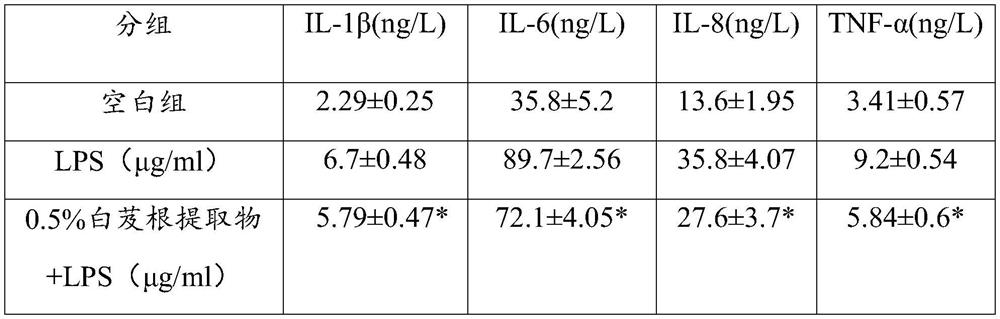

Examples

Embodiment 1

[0042] Add 150 g of flaky Bletilla striata into pure water 10 times the weight of the raw material, extract at 70°C for 3 hours, and after the extraction is completed, filter and remove the residue while it is hot to obtain the coarse filtrate of Bletilla striata, adjust the temperature of the coarse filtrate to 60°C, and add 5wt% acid protease , keep warm for 1 hour for enzymolysis, when the enzymolysis is over, raise the temperature to 80°C, add 5wt% high-temperature amylase, and keep warm for 1 hour for enzymolysis. Enzymolysis ends, in enzymolysis solution, add 15wt% white diatomaceous earth filter aid, obtain fine filtrate, add the ion exchange resin (preferably 717 resin) of raw material weight 15wt% in fine filtrate, stir and adsorb for 1 hour, adsorption ends After filtration, HCl was added to the filtrate to adjust the pH value to 6. With the filtrate after adjusting the pH, adjust the temperature to 70°C, add raw material weight 8wt% activated carbon to the feed liqu...

Embodiment 2

[0044] Add 150 g of flaky Bletilla striata into pure water 15 times the weight of the raw material, and extract at 90°C for 1 hour. After the extraction is completed, filter and remove the slag while it is hot to obtain the coarse filtrate of Bletilla striata, adjust the temperature of the coarse filtrate to 40°C, and add 0.05wt% of Acid protease, keep warm for 6 hours for enzymolysis, after the end of the enzymolysis, raise the temperature to 80°C, add 0.05wt% high-temperature amylase, keep warm for 6 hours for enzymolysis. Enzymolysis ends, in enzymolysis solution, add 4wt% white diatomite to aid filter, obtain fine filtrate, add the ion exchange resin (preferably 717 resin) of raw material weight 4wt% in fine filtrate, stir and adsorb for 6 hours, adsorption ends After filtration, HCl was added to the filtrate, and the pH of the filtrate was adjusted to 6. With the filtrate after adjusting the pH, adjust the temperature to 50°C, add raw material weight 2wt% activated carbon...

Embodiment 3

[0046]Add 150 g of flaky Bletilla striata into pure water 12 times the weight of the raw material, and extract at 80°C for 2 hours. After the extraction is completed, filter and remove the slag while it is hot to obtain the coarse filtrate of Bletilla striata, adjust the temperature of the coarse filtrate to 50°C, and add 2.5wt% of Acid protease, keep warm for 3 hours for enzymolysis, after the end of the enzymolysis, raise the temperature to 90°C, add 2.5wt% high-temperature amylase, keep warm for 3 hours for enzymolysis. Enzymolysis ends, in enzymolysis solution, add 10wt% white diatomaceous earth to aid filter, obtain fine filtrate, add the ion exchange resin (preferably 717 resin) of raw material weight 10wt% in fine filtrate, stir and adsorb for 3 hours, adsorption ends After filtering, add HCl to the filtrate to adjust the pH value of the filtrate to 6. Adjust the temperature of the filtrate after pH adjustment to 60°C, add 6wt% activated carbon by weight of raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com