Single emulsifier based on DNA triangular origami technology and preparation method and application of double emulsion

A technology of double emulsion and emulsifier, applied in cosmetic preparations, preparations for skin care, medical preparations containing active ingredients, etc., to achieve the effect of good stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation method based on the single emulsifier stable double emulsion of DNA triangular origami technology, concrete steps are as follows:

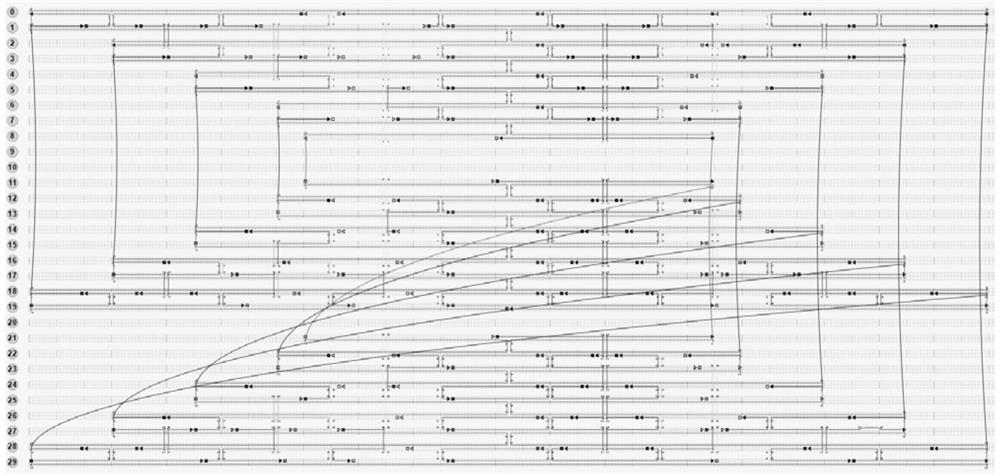

[0044] (1) see figure 1 , each block unit of DNA triangular origami was designed in caDNAno software, and DNA staple chains were obtained at the same time, as shown in Table 1:

[0045] In sequence SEQ ID NO.2, SEQ ID NO.5, SEQ ID NO.6, SEQ ID NO.10, SEQ ID NO.13, SEQ ID NO.18, SEQ ID NO.19, SEQ ID NO.20, SEQ ID NO.24, SEQ ID NO.31, SEQ ID NO.36, SEQ ID NO.43, SEQ ID NO.47, SEQ ID NO.54, SEQ ID NO.57, SEQ ID NO.62, SEQ ID NO. 63, SEQ ID NO.65, SEQ ID NO.66, SEQ ID NO.67, SEQ ID NO.68, SEQ ID NO.72, SEQ ID NO.77, SEQ ID NO.78, SEQ ID NO.82, SEQ ID NO.82, SEQ ID NO. ID NO.83, SEQ ID NO.87, SEQ ID NO.97, SEQ ID NO.99, SEQ ID NO.105, SEQ ID NO.111, SEQ ID NO.112, SEQ ID NO.116, SEQ ID NO. 119, SEQ ID NO.126, SEQ ID NO.129, SEQ ID NO.135, SEQ ID NO.136, SEQ ID NO.139, SEQ ID NO.141, SEQ ID NO.142, SEQ ID NO.145, SEQ ID N...

Embodiment 1

[0081]Both the inner and outer water phases of the W / O / W emulsion of Example 1 contained 10 μM of the DNA triangular origami of Example 1, and the inner and outer water phases of the W / O / W emulsion of Comparative Example 1 contained 10 μM of the DNA triangular origami of Comparative Example 1, Both the inner and outer water phases of the W / O / W emulsion of Comparative Example 2 contained 5 μM of the DNA triangular origami of Comparative Example 2, the oil phase of the W / O / W emulsion of Comparative Example 3 contained 10 μM of PGPR, and the outer aqueous phase contained 10 μM of Tween 80 . To study in vitro release, 1 mL of the prepared W / O / W emulsion was placed in PBS solution at physiological pH=7.4. The mixture was shaken at 200 rpm and then centrifuged at different time intervals (4, 8, 12, 16, 20 and 24 hours). The HPLC method was used to evaluate the in vitro release profile.

[0082] In vivo whitening experiment in zebrafish

[0083] Both the inner and outer water phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com