Fluid pressure measuring device based on fluid statics principle

A technology of hydrostatics and fluid pressure, which is applied in the direction of fluid pressure measurement, measuring device, and measurement of fluid pressure using liquid as a pressure-sensitive medium. problems, to avoid constant compression, increase the measurement range, and reduce the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

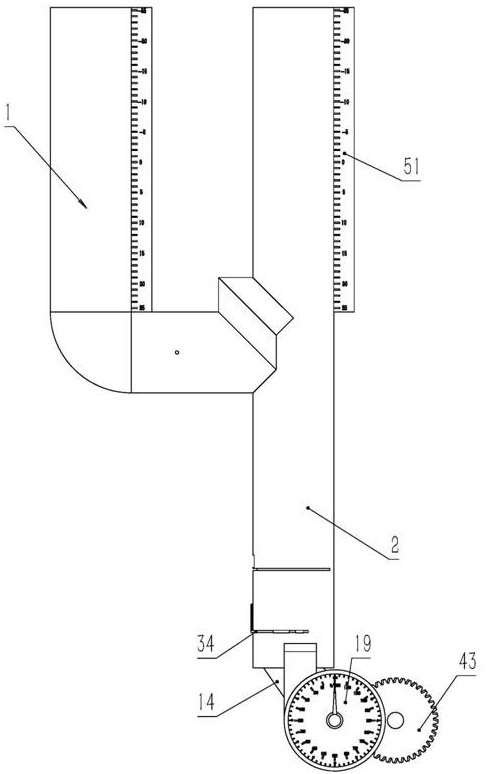

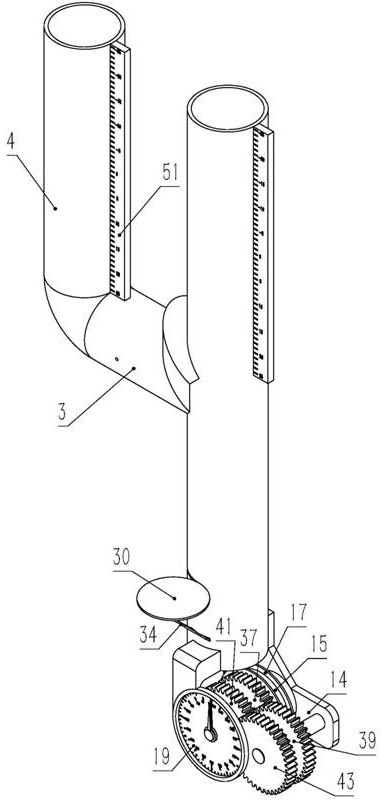

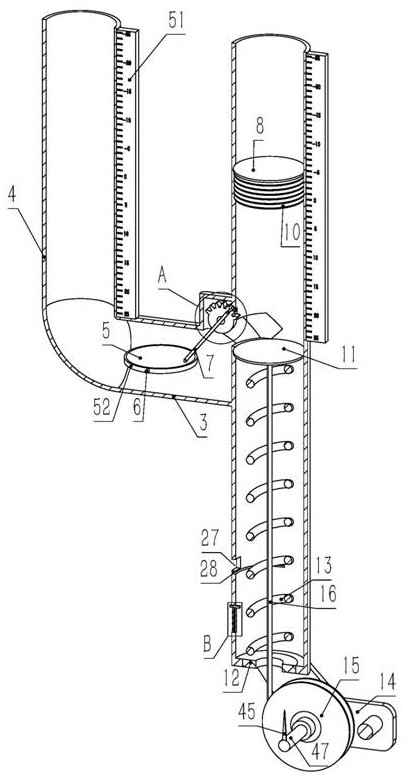

[0031]Embodiment 1. A fluid pressure measuring device based on the principle of hydrostatics, comprising a pressure measuring tube, the pressure measuring tube includes a U-shaped pipe 1 and a relief pipe 2, and the U-shaped pipe 1 is composed of a transition pipe section 3 arranged transversely It is composed of two vertical measuring pipe sections 4, and the two measuring pipe sections 4 are arranged side by side and placed on the left and right sides of the transition pipe section 3 respectively. The left and right ends of the transition pipe section 3 correspond to the two measuring pipe sections 4 one by one. The end of the pipe is connected with the lower end of the corresponding measuring pipe section 4, that is, the two measuring pipe sections 4 are connected through the transition pipe section 3, the relief pipe 2 is coaxial with the measuring pipe section 4 on the right side of the transition pipe section 3, and the inner diameter of the relief pipe 2 and the transitio...

Embodiment 2

[0033] Embodiment 2, on the basis of Embodiment 1, the positioning shaft 6 is set along the front-to-back direction, the gear mechanism includes an incomplete gear 20 placed in the transition pipe section 3, and the axis of the incomplete gear 20 is set along the front-to-back direction. The complete gear 20 is placed on the upper right side of the transition pipe section 3, and the transition pipe section 3 has a fixed shaft 21 pierced in the inner hole of the incomplete gear 20, and the side wall of the fixed shaft 21 is provided with an arc-shaped limit Slot 22, the arc-shaped path of the limiting groove 22 is coaxial with the fixed shaft 21, and the incomplete gear 20 has a limiting block 23 placed in the limiting groove 22 and slidingly matched with the limiting groove 22, forming an incomplete The limit rotation connection between the complete gear 20 and the transition pipe section 3, at this time the limit block 23 is located at the start position of the limit groove 22...

Embodiment 3

[0034] Embodiment 3, on the basis of Embodiment 1, a pressure relief hole 27 close to the bottom end of the relief pipe 2 is opened on the side wall of the relief pipe 2. When the measured fluid pressure exceeds the range of the dial 19, Under the action of the measured fluid pressure, the pressure plate 8 will pass over the pressure relief hole 27, so that the measured fluid pressure will be released from the pressure relief hole 27, so as to prevent the device from being damaged due to high pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com