Flat-bulb steel ball head measuring tool and method for measuring thickness of ball head by using same

A technology for measuring tooling and bulb flat steel, applied in the direction of mechanical thickness measurement, etc., can solve the problem that the ball end fillet radius cannot be measured, cannot meet the welding requirements, and the size of the two ball heads is inconsistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

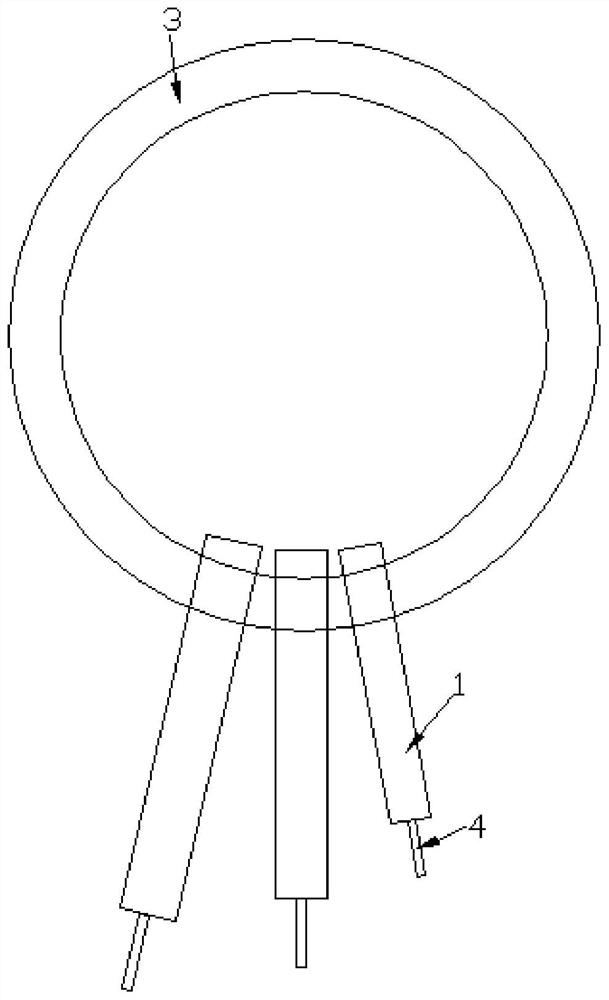

[0020] Such as Figure 1 to Figure 2 As shown, the present invention is a kind of spherical flat steel ball head measuring tool, including several pieces of measuring calipers 1, and the measuring calipers 1 are provided with arc grooves 2 adapted to the ball heads of different sizes of spherical flat steel, on the measuring calipers 1 The end away from the arc groove 2 is provided with a hanging hole, and the measuring caliper 1 is connected with the hanging ring 3 through the hanging hole; the measuring caliper 1 is provided with a marking layer for marking the radius of the rounded corner of the spherical flat steel ball head. The measuring caliper 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com