Ceramic tile laying structure and laying method thereof

A ceramic tile and the same technology, applied to the ceramic tile laying structure and the laying field, can solve the problems of waiting for the cement mortar to solidify, the laying process is cumbersome, etc., and achieve the effects of improving the laying efficiency, rapid erection, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

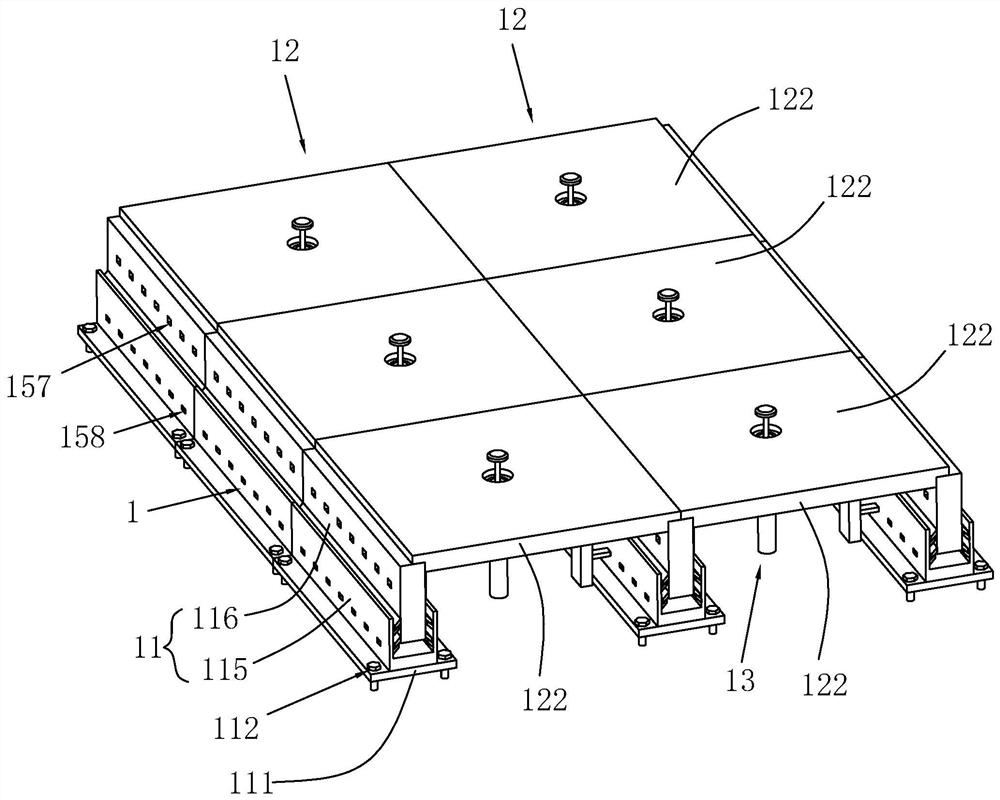

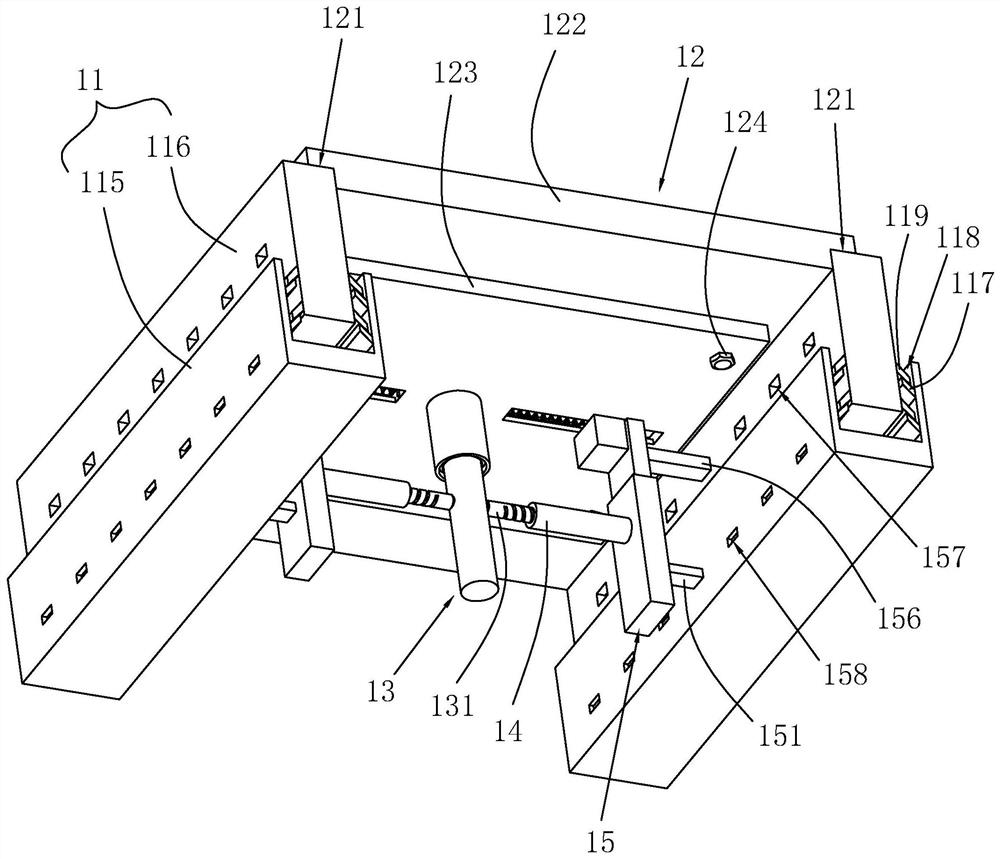

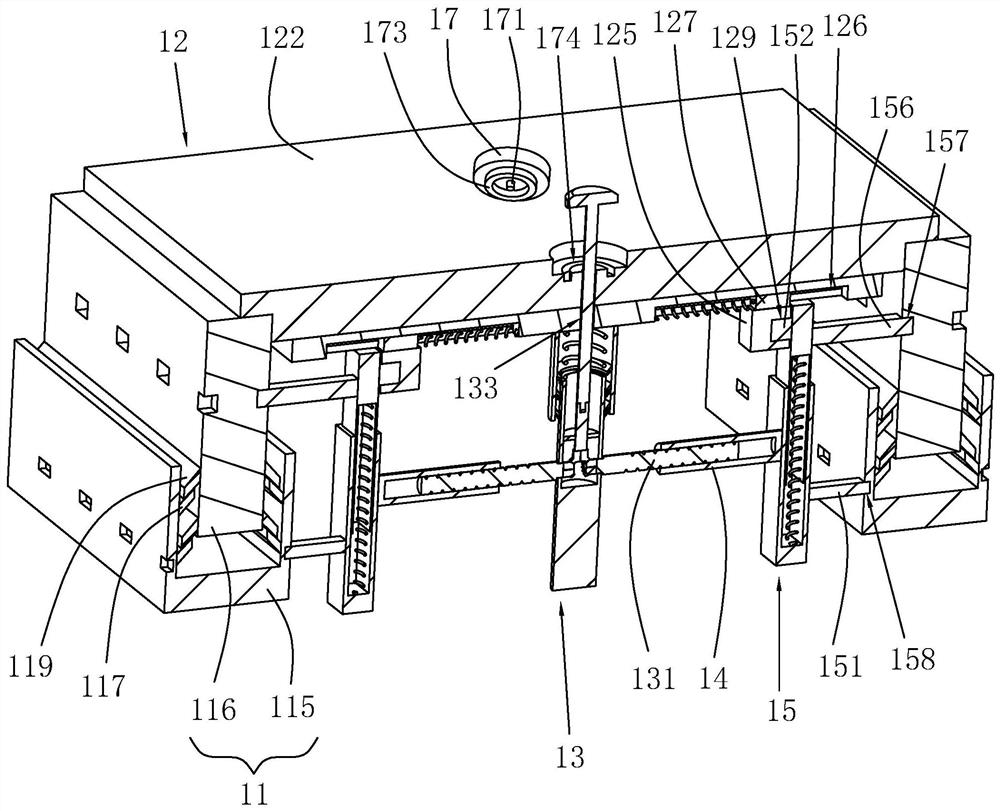

[0042] The embodiment of the present application discloses a ceramic tile laying structure. refer to figure 1 , a tile laying structure, comprising a plurality of fixed bars 1 spaced apart from each other and arranged in parallel, each fixed bar 1 includes a plurality of connecting bars 11 located on the same straight line, the bottom of each connecting bar 11 is along the connecting bar 11 A mounting plate 111 is provided in the lengthwise direction of the mounting plate 111 for abutting against the ground base, and a plurality of mounting holes 112 for bolts to pass through are opened on the mounting plate 111.

[0043] combine figure 1 with figure 2 , a decorative board 12 is placed between every two adjacent fixing strips 1, in order to drive the adjacent decorative boards 12 to abut together, there are holes on both sides of each decorative board 12 for the fixing strip 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com