Anti-wall sticking fermentation device based on combined stirring

The technology of a fermentation device and a stirring device is applied in the fields of fermentation devices and anti-adherence fermentation devices, which can solve the problems of low mass transfer efficiency, etc., and achieve the effects of large dissolved oxygen, avoiding product accumulation and small shearing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

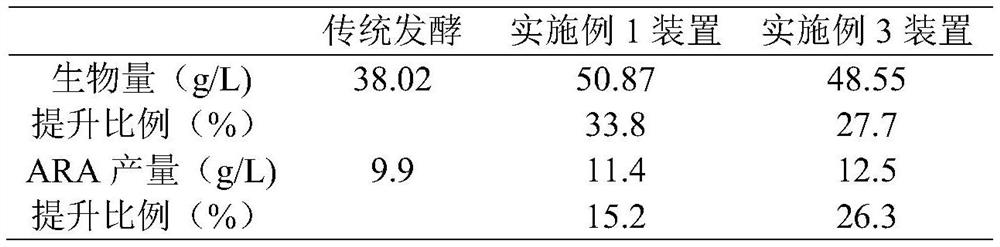

Examples

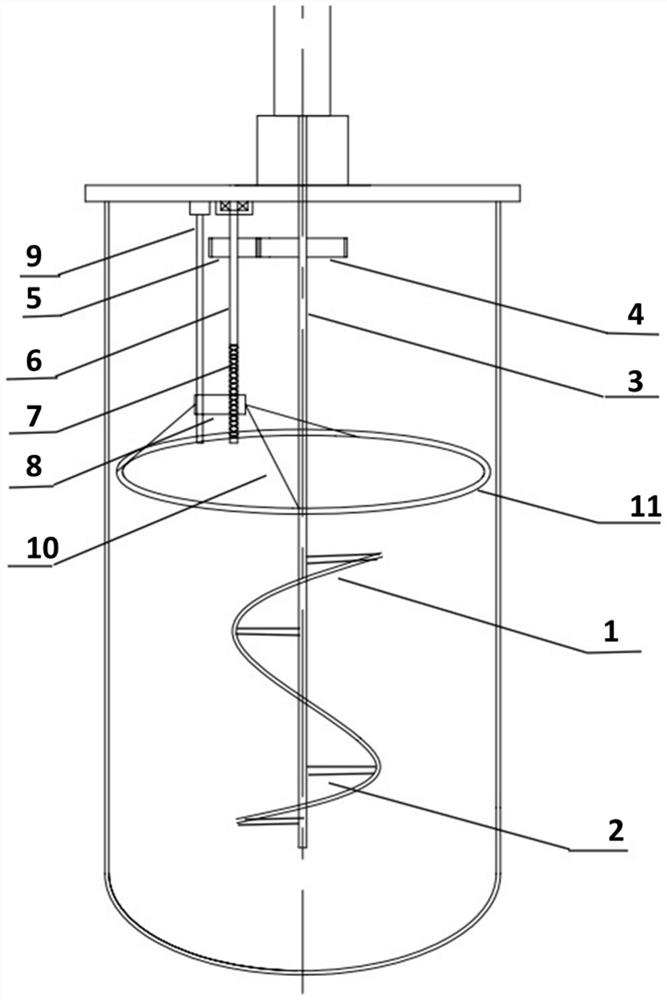

Embodiment 1

[0018] The anti-adherence fermentation device based on combined stirring includes a tank body, a stirring device and an anti-adherence system arranged inside the tank body. The tank radius R is 1 m. The stirring device includes a stirring shaft 3 and a stirring paddle; the stirring shaft 3 is fixedly connected with a driving gear 4, and the driving gear 4 meshes with the transmission gear 5 to obtain power. The stirring paddle is a ribbon-type stirring paddle 1, and the ribbon-type stirring paddle 1 is connected to the stirring shaft 3 through a connecting rod 2. The length d of the connecting rod 2 1 0.8m (0.5-0.8 times the tank radius R). The ribbon width of the ribbon type stirring paddle 1 is 8cm. The pitch d of the screw-type stirring paddle 1 2 is 0.8m (0.5-2 times of D), and the diameter D of the stirring paddle is 1.6m; the rotating speed of the ribbon type stirring paddle 1 is 20-100rpm.

[0019] The anti-adherence system is composed of a transmission rod 6, a sl...

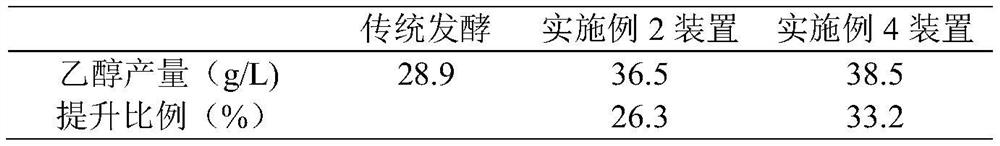

Embodiment 2

[0020] Embodiment 2: Different from Embodiment 1,

[0021] The tank radius R of the anti-adherence fermentation device based on combined stirring is 0.6m. The length d of the connecting rod 2 1 It is 0.48m (0.5-0.8 times of the tank radius R). The ribbon width of the ribbon type stirring paddle 1 is 5cm. The pitch d of the screw-type stirring paddle 1 2 The diameter D is 1.92m (0.5-2 times of D), and the diameter D is 0.96m; the rotating speed of the ribbon type stirring paddle 1 is 20-100rpm.

[0022] The annular scraper is inclined upward in the vertical direction, and the angle between the edge of the annular scraper 11 and the side wall of the tank body is 30°. The radius ratio between the transmission gear 5 and the driving gear 4 is 20. A plurality of circular holes with a diameter of 2 cm are arranged on the ribbon-type stirring paddle 1, and the distance between the adjacent circular holes is 30 cm. The ratio of the length to the pitch of the two-way thread 7 is ...

Embodiment 3

[0023] Embodiment 3: Different from Embodiment 1,

[0024] The tank radius R of the anti-adherence fermentation device based on combined stirring is 1.5m. The length d of the connecting rod 2 1 1m. The ribbon width of the ribbon type stirring paddle 1 is 7cm. The pitch d of the screw-type stirring paddle 1 2 The diameter is 1.2m (0.5-2 times of D), and the diameter D is 2m; the rotating speed of the ribbon stirring paddle 1 is 20-100rpm.

[0025] The annular scraper is inclined upward in the vertical direction, and the angle between the edge of the annular scraper 11 and the side wall of the tank body is 35°. The radius ratio between the transmission gear 5 and the driving gear 4 is 2. A plurality of round holes with a diameter of 1 cm are arranged on the ribbon-type stirring paddle 1, and the distance between the adjacent round holes is 38 cm. The ratio of the length to the pitch of the two-way thread 7 is 50:1; the distance between the tip of the annular scraper 11 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com