A kind of inorganic energy storage ceramic luminous material and preparation method thereof

A technology of luminescent materials and luminescent materials, which is applied in the field of inorganic energy storage ceramic luminous materials and its preparation, can solve the problems of multi-light energy, the influence of continuous luminous ability, and damage to the luminous performance of luminescent materials, so as to improve the application range and good absorption. Thermoluminescence, good light absorption and luminescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

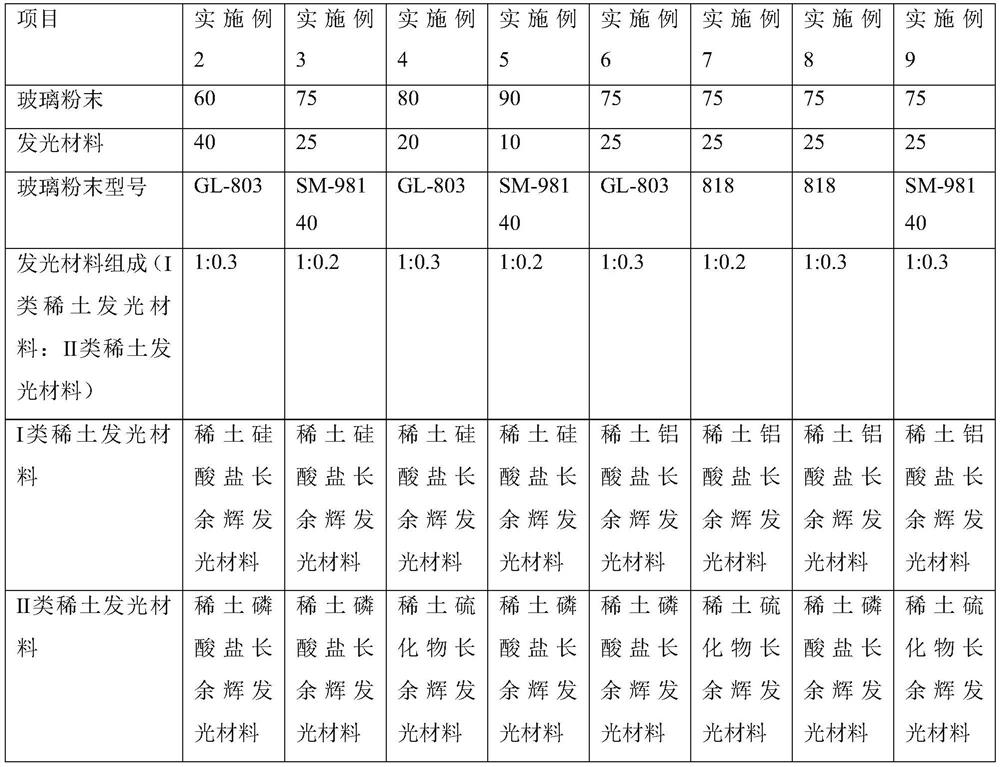

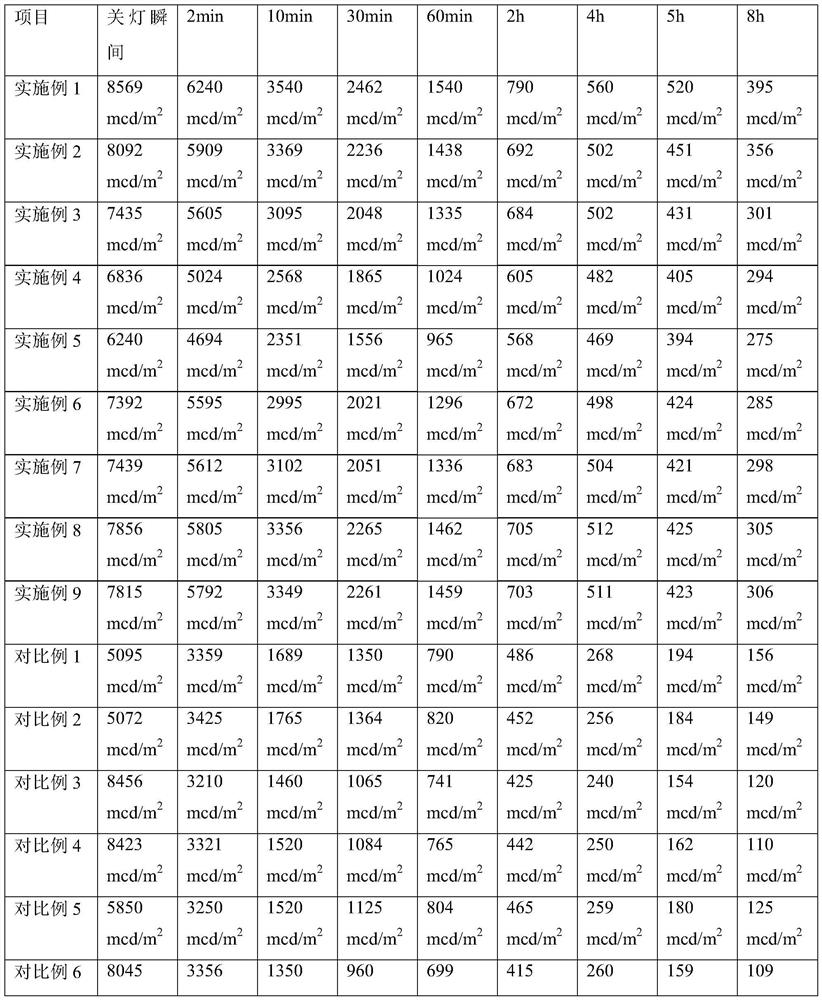

Examples

Embodiment 1

[0036] An inorganic energy-storing ceramic luminous material is prepared from 50 parts of glass powder and 50 parts of luminescent material, wherein the model of the glass powder is SM-98140, and its particle size mesh is 100 meshes; the luminescent material is made of rare earth silicate The long afterglow luminescent material and the rare earth phosphate long afterglow luminescent material are mixed in a weight ratio of 1:0.2, and the particle size of the luminescent material is 100 meshes.

[0037] The inorganic energy storage ceramic luminous material is made according to the following steps:

[0038] 1. Mixing and stirring: transfer the glass powder and luminescent material into a mixer, and stir for 15 minutes at a stirring speed of 500 r / min to obtain a well-mixed mixture.

[0039] 2. Baking: Put the mixture into the mold, where the thickness of the mixture in the mold is 10mm, and then put the mold into the automatic heating rotary kiln for heating, baking and cooling....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com