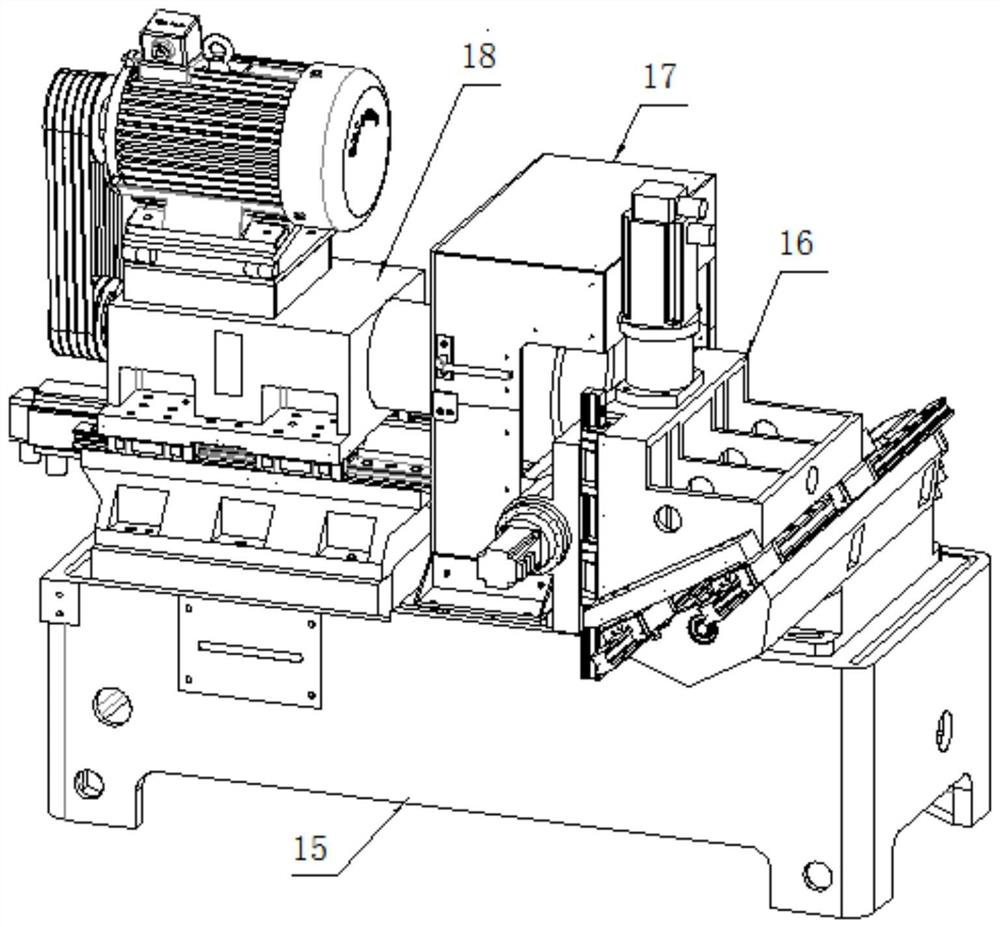

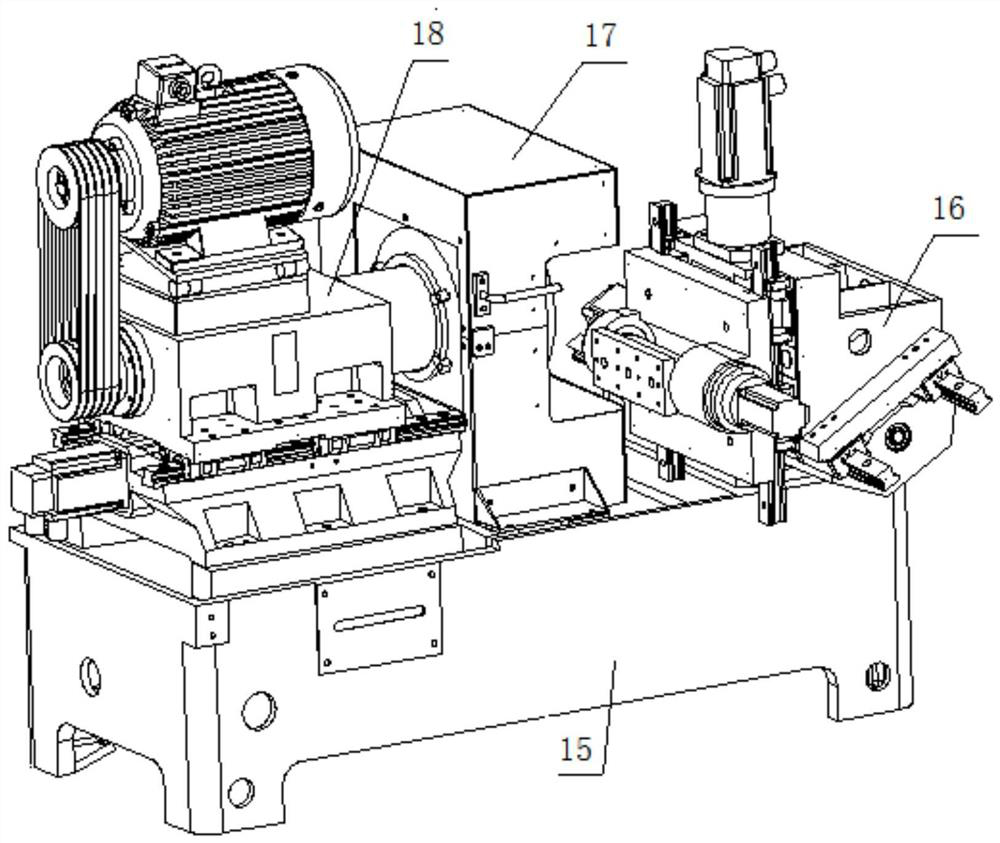

Four-axis linkage lifting type numerical control end face tool sharpener

A four-axis linkage, lifting technology, applied in the direction of grinding frame, grinding bed, grinding slide, etc., can solve the problems of low running accuracy, inability to adapt to high-precision CNC operation, slow response speed, etc., to achieve The structure is compact and stable, the cost of assembly labor is saved, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

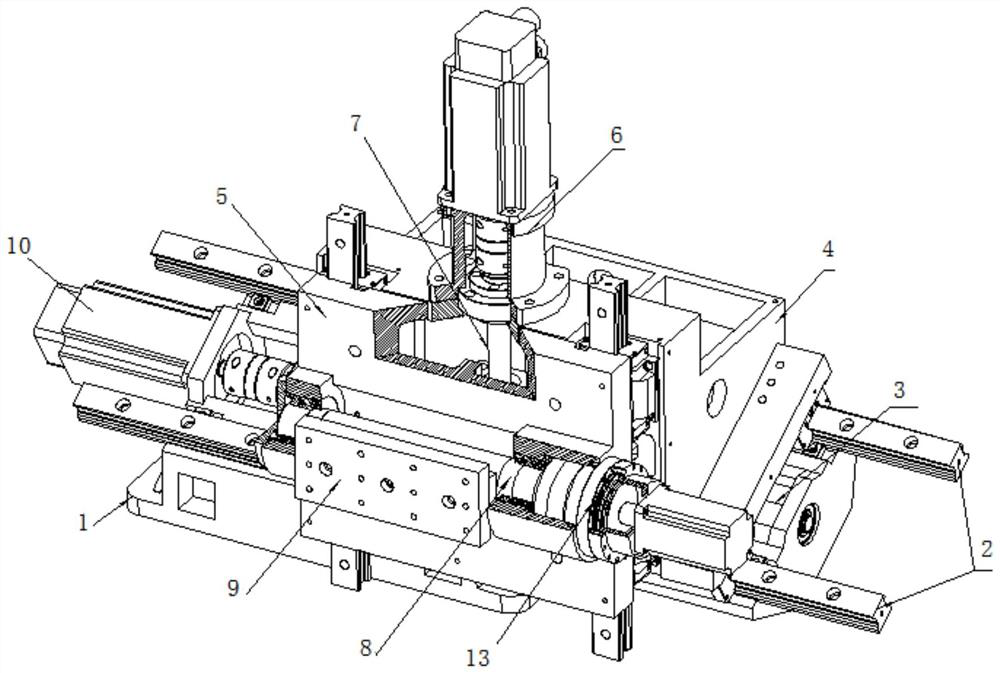

[0038] When the present invention is used, the following functions can be realized by matching with the CNC machine tool control system of the prior art for control;

[0039] When the X-axis is running, the X-axis servo motor 10 drives the X-axis screw 3 to rotate, and the screw nut is connected to the middle carriage 4, so that the middle carriage 4 runs left and right along the linear guide rail 2;

[0040] When the Y-axis is running, the Y-axis servo motor 11 drives the lifting screw mandrel 7 to rotate, so that the lifting slide plate 5 and the linear guide rail 2 fixed on the lifting slide plate 5 are lifted together.

[0041] When the Z-axis is running, the Z-axis servo motor 23 drives the Z-axis screw 22 to rotate, and the screw nut is connected with the headstock mount 21 to make the headstock mount 21 run back and forth along the Z-axis guide rail 20 .

[0042] When the A shaft was running, the A shaft servo motor 12 drove the A shaft RV speed reducer 13 to rotate, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com