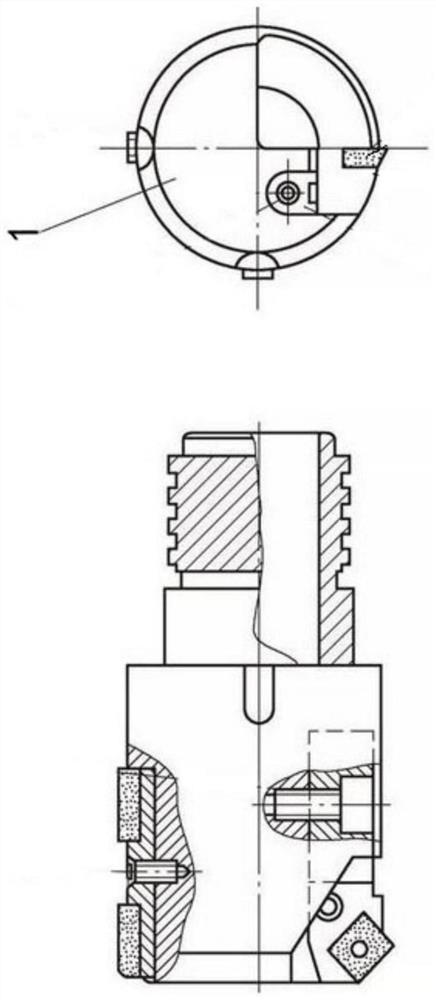

Numerical control large-diameter deep hole semi-fine boring head device

A semi-finish boring and large-diameter technology, which is applied in the direction of boring head, turning equipment, tool holder accessories, etc., can solve the problems of workpiece size change, inconsistent inner hole size inlet and outlet, and old structure of large hole boring tools, etc., to achieve The effect of stable processing size, lower skill requirements and saving consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Other objects and advantages of the present invention will become clear by explaining the following preferred embodiments of the present invention.

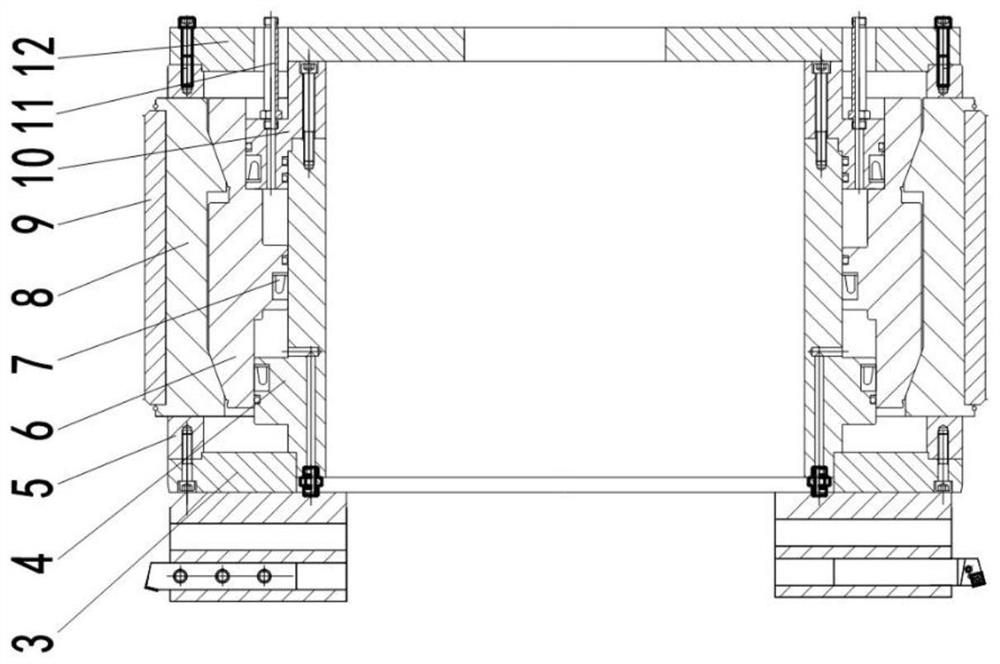

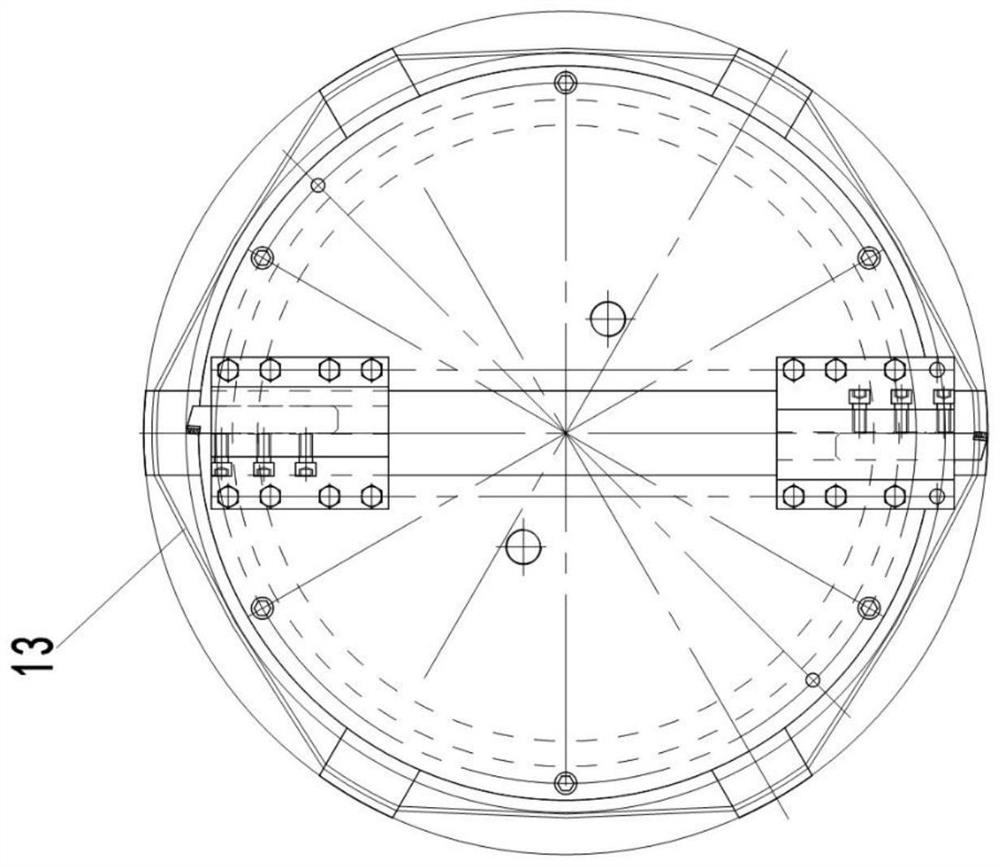

[0033] Figure 1-Figure 13 It shows a structural schematic diagram of a CNC large-diameter deep-hole semi-finishing head device proposed by the present invention. For the convenience of description, the "up", "down", "left" and "right" referred to below are consistent with the up, down, left and right directions of the drawings themselves, but do not limit the structure of the present invention.

[0034] Such as Figure 1-Figure 13 As shown, a CNC large-diameter deep-hole semi-finishing boring head device includes a boring head body 5, a cutter body 17, a support bar compensation structure and a cutter body compensation structure, wherein: the support bar compensation structure includes a fixed piston 4, a drive member and The moving body 8, the fixed piston 4 is fixedly connected to the boring head body 5, the driving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com