Cold feed metal removing device

A technology of cold feeding and metal, which is applied in the field of cold feeding metal removal equipment, can solve the problems that it is difficult to ensure the removal of metal foreign matter, difficult to remove, and easy to detect metal, so as to achieve reliable removal of metal foreign matter, high work efficiency and low labor cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

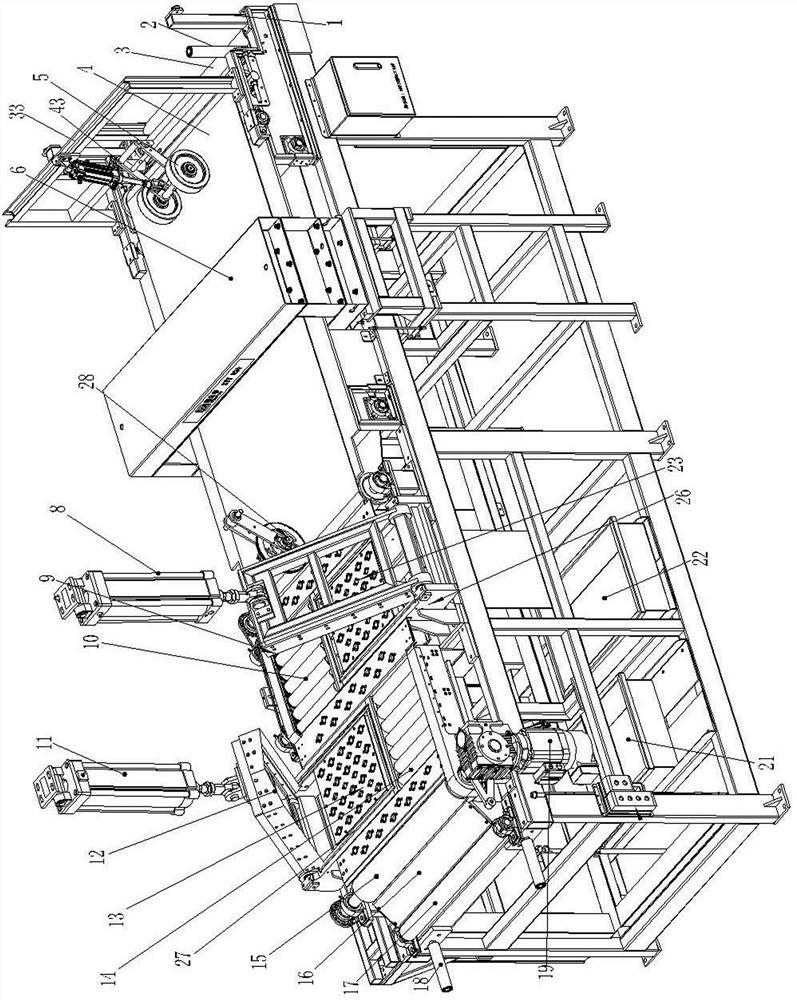

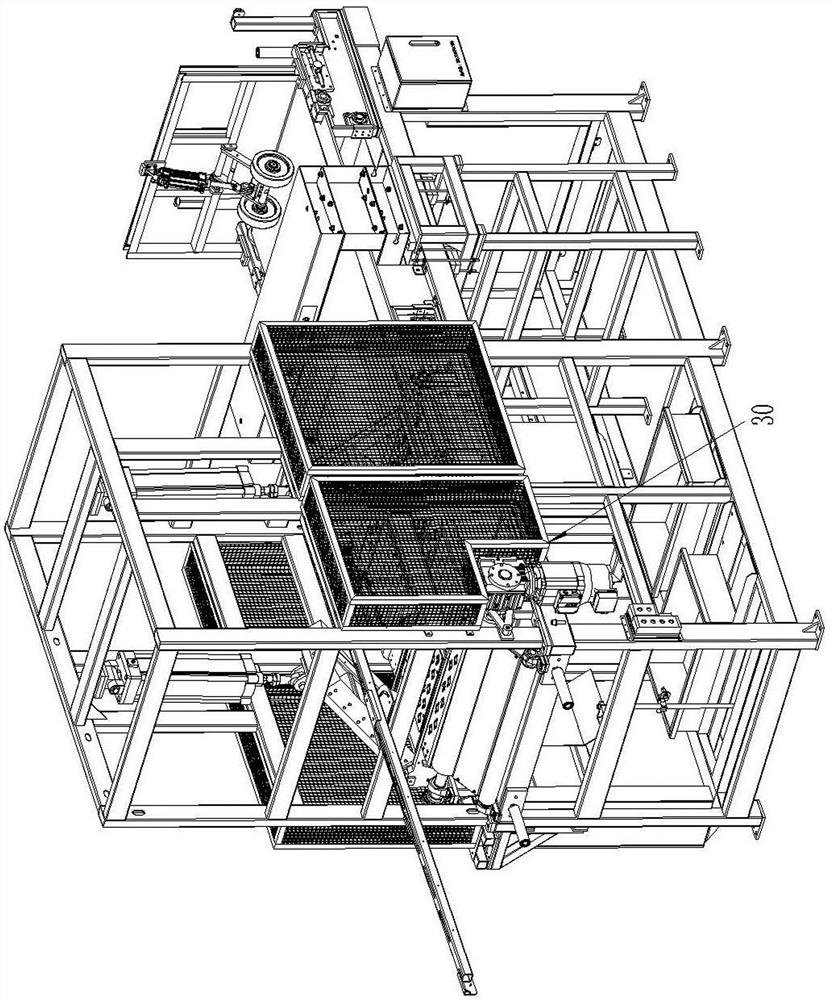

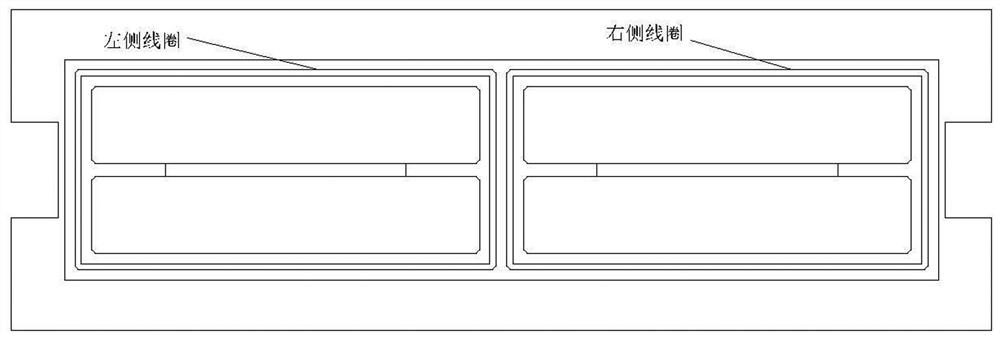

[0033] As shown in the figure, the present invention includes a main frame, on which a transport part is arranged, and the transport part carries the transported parts so that the transported parts pass sequentially through the metal detector 6 on the main frame for judging the location of metal impurities on the rubber compound , A cutting mechanism used to cut off the rubber material where the metal impurities are located.

[0034] The metal detector 6 is arranged on the upper end of the independent bracket of the metal detector.

[0035] The conveying parts include a conveying belt at the front and a driving roller at the rear, the conveying belt passes through the metal detector 6, and the driving roller is arranged on the side of the cutting mechanism.

[0036] Both sides of the front end of the conveyor belt are provided with vertical entrance rubber rollers 2, the lower end of the front part of the entrance rubber roller 2 is provided with a horizontal entrance rubber r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com